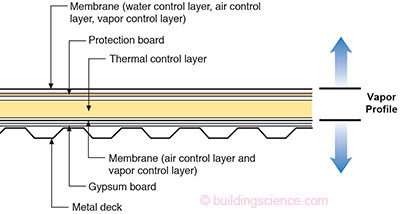

Huh? Blasphemy. Yeah, well, in some assemblies, it is actually a pretty good idea. The most famous "double vapor barrier" of them all is a classic compact flat roof. Check out Figure 1. The roof membrane on the "top" is clearly a vapor barrier. In fact, it is almost a "perfect" vapor barrier. And the membrane on the "bottom" is also a vapor barrier. The "bottom" membrane's primary function is that of an air barrier but it's material characteristics are such that historically it has also been a vapor barrier.

Figure 1: Classic Compact Flat Roof—The most famous "double vapor barrier" of them all. The roof membrane on the "top" is clearly a vapor barrier. In fact, it is almost a "perfect" vapor barrier. And the membrane on the "bottom" is also a vapor barrier. The "bottom" membrane's primary function is that of an air barrier but it's material characteristics are such that historically it has also been a vapor barrier.

The misunderstanding of the difference of this "vapor barrier" versus "air barrier" function in compact flat roofs goes back generations. We still have, to this day, roofing consultants, manufacturers and architects referring to this lower membrane as a vapor barrier rather than an air barrier. In fairness, it actually has been a vapor barrier, but its more important function has been that of an air barrier.1

So, in classic compact flat roofs we have double vapor barriers. And we have had them for a long time. And in millions upon millions of square feet of roofs. How come they work? Easy. They are pretty much "perfect" double vapor barriers and double air barriers. The upper and lower membranes are both airtight and vapor tight. Note that the airtightness is more important.2 Moisture can't get into the assembly from the top and moisture can't get into the assembly from the bottom and that is why these roofs work.3

Compact flat roofs have some interesting history. When they were "black" and fully adhered they did not need air barrier "bottom" membranes in most climate zones. You could get away without a "bottom" membrane up to International Energy Conservation Code (IECC) Climate Zone 5 in commercial office buildings and warehouses – places with low interior moisture loads – if you had a "black" membrane. Note we are not talking museums, hospitals, indoor swimming pools and the like.

Interior moisture would travel upward hit the underside of the black roof membrane stop and then be driven back down when the black membrane got hot. And that back membrane would get real hot. Real, real, real hot – 180 degrees F hot. That thermonuclear sphere 93 million miles away gives off quite a bit of energy. We had pingpong water. It went up and then got bounced back due to solar radiation. Life was easy. Then membranes became “white”. They didn’t get so hot. White membranes were “cool” – 120 degrees F cool. The interior moisture that traveled upwards didn’t get bounced back as much and we began to have problems even in office buildings and warehouse roof assemblies. We now needed air barriers. We put them in and the problems disappeared. Note that these air barriers were almost always vapor barriers.

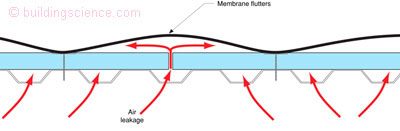

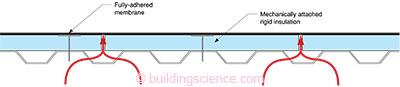

So where does the fully adhered part come into play? Check out Photograph 1 and Figure 2. We were here way back when (BSI-019: Uplifting Moments—Roof Failures). With a mechanically attached membrane and no bottom side air barrier the roof membrane “flutters”. This does not happen with a fully adhered membrane (Figure 3) or with a bottom side air barrier. With a bottom side air barrier the wind load that a roof membrane “sees” is now “shared” between the lower membrane and the upper membrane. Blow-offs are reduced. This is a good thing.

Photograph 1: Missing Air Barrier—With a mechanically attached membrane and no bottom side air barrier the roof membrane “flutters”.

Figure 2: Fluttering Roof Membrane—When a mechanically attached roof membrane experiences suction or uplift from wind air is pulled into the roof assembly from the building interior if an underside air barrier is not present.

Figure 3: Fully Adhered Roof Membrane—The suction wind load is taken almost completely by the fully adhered roof membrane if an underside air barrier is not present.

So lets go back to Figure 1. The “vapor profile” clearly is one of a “double vapor barrier” and it works. It works fabulously well and has done so for a very, very long time in all the climate zones. So much for the “common wisdom” of never having “double vapor barriers”. Yeah, but roofs don’t count4. What about walls?

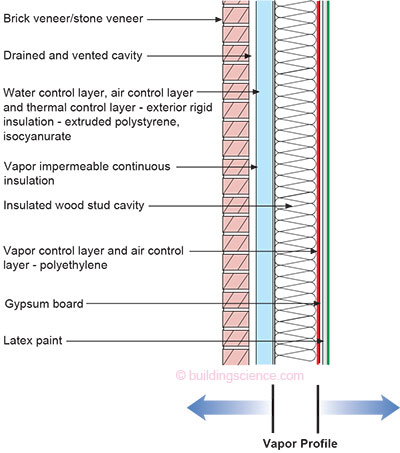

Let’s look at walls with “double vapor barriers”. Some work, some do not. The reasons why are important. Check out Figure 4. A “classic” wood frame wall with foam sheathing – a wall that we have been building in cold climates for 40 years. The foam sheathing on the exterior is clearly a vapor barrier. And the sheet polyethylene on the interior is also clearly a vapor barrier. The “vapor profile” is that of a “double vapor barrier”. I grew up with this wall in Ontario - 2x6 wall with R-5 foam sheathing (Photograph 2) coupled with unfaced fiberglass batt cavity insulation covered with an interior 6 mil poly air/vapor barrier (Photograph 3). This wall is currently being built all over Minnesota and Wisconsin. It is still being built in Ontario. And it works. We know that it works because we have been building it for so long without problems. So why does it work? The reasons are somewhat different than the discussion we just had with compact flat roofs. Not completely different, but somewhat different.

Figure 4: Double Vapor Barrier Wall Assembly That Works—The “vapor profile” is that of a “double vapor barrier”. We know that it works because we have been building it for so long.

Photograph 2: “Classic” Wood Frame Wall With Foam Sheathing—A wall that we have been building in cold climates for 40 years. The foam sheathing on the exterior is clearly a vapor barrier. The “vapor profile” is that of a “double vapor barrier”. I grew up with this wall in Ontario—2x6 wall with R-5 foam sheathing and a plastic interior air/vapor barrier.

Photograph 3: Interior Polyethylene Vapor Barrier—The sheet polyethylene on the interior is clearly a vapor barrier. In this assembly it is also acting as an air barrier (air control layer).

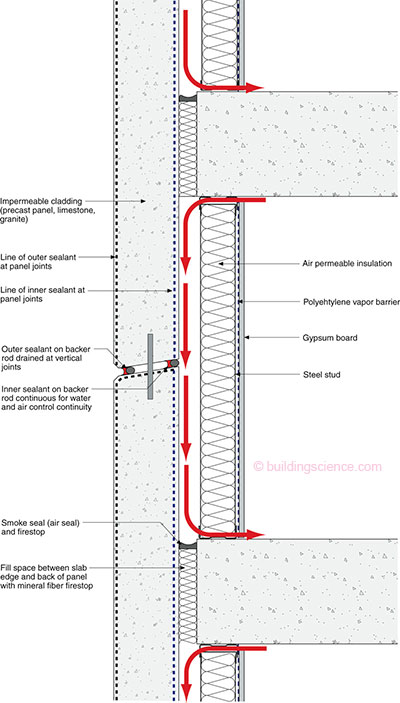

The best place to start on understanding this wall is look at walls with double vapor barriers that do not work. We were also here way back when (BSI-054: High Risk Walls). Figure 5 illustrates a double vapor barrier wall that does not work. So what’s going on in this wall? The outer precast (the exterior vapor barrier) is significantly more airtight than the interior polyethylene sheet (the interior vapor barrier). It gets worse. The interior surface of the outer precast is also “cold” during the heating season as it has pretty much no thermal resistance. We have an “air leakage” problem coupled with a cold “condensing surface” problem. Note that we did not have the air leakage problem in the compact flat roof assemblies we looked at.

Figure 5: Double Vapor Barrier Wall Assembly That Does Not Work—The outer precast (the exterior vapor barrier) is significantly more airtight than the interior polyethylene sheet (the interior vapor barrier). It gets worse. The interior surface of the outer precast is also "cold" during the heating season as it has pretty much no thermal resistance. We have an "air leakage" problem coupled with a cold "condensing surface" problem.

It is not typically possible to the make both the inside and outside of walls perfectly airtight. This is different than our ability to make the top membrane and bottom membrane of compact flat roofs more or less perfectly airtight. Walls are more complex than roofs. If we built walls the same way we built roofs it would be a different story. We do not. We have windows. We have architects. We have gazillion claddings. Argh!

If the outside is “leakier” than the inside we reduce the risk. And if the condensing surface temperature is warmer we reduce the risk. And finally, if the interior moisture loads are not extreme, we reduce the risk. So houses with foam sheathing in cold climates with interior vapor barriers with good interior air sealing that are not humidified and pressurized to hospital and art gallery performance metrics work.

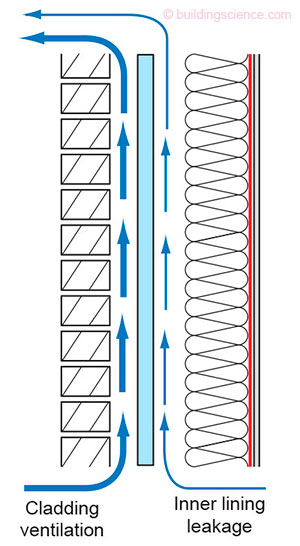

Figure 6 illustrates what is typically going on. The interior poly is never “perfect” but it is pretty, pretty darn good. You don’t believe me go visit some building sites in Minneapolis and Mississauga and Menomonie. Note that the exterior foam is never “perfect”. It is pretty darn good, but not as good as the interior poly. And even better, the foam has a thermal resistance. Not much moisture condenses and the stuff that condenses dries outward. We know this because the walls have been working. And we have been measuring them. In lots of places over many decades.5

Figure 6: Why The Wall Works—The interior poly is never “perfect” but it is pretty, pretty darn good. Note that the exterior foam is never “perfect”. It is pretty darn good, but not as good as the interior poly. And even better, the foam has a thermal resistance. Not much moisture condenses and the stuff that condenses dries outward.

Let me remind everyone once again that the key to these walls is the airtightness and vapor tightness of the interior lining. If you don’t have an “interior” air barrier and an “interior” vapor barrier your exterior vapor barrier is going to have to have a lot more thermal resistance to control condensation. We were here before (BSI-049: Confusion About Diffusion). The model codes recognize this and provide guidance on how to construct walls without interior vapor barriers or air barriers in cold climates.

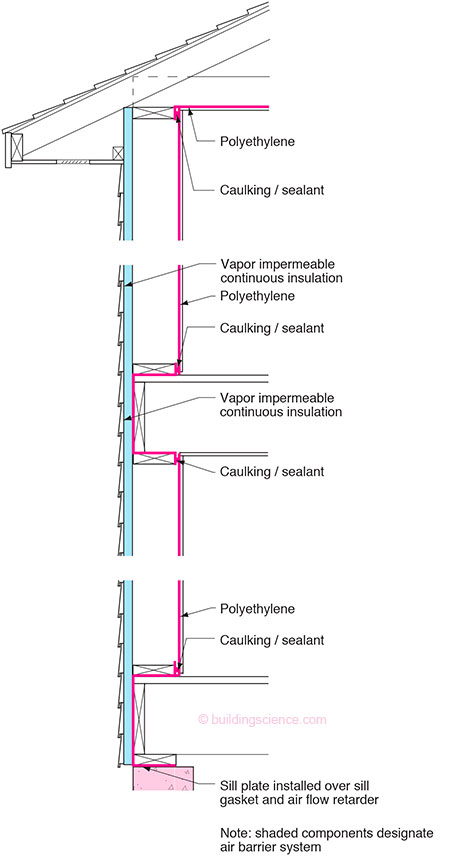

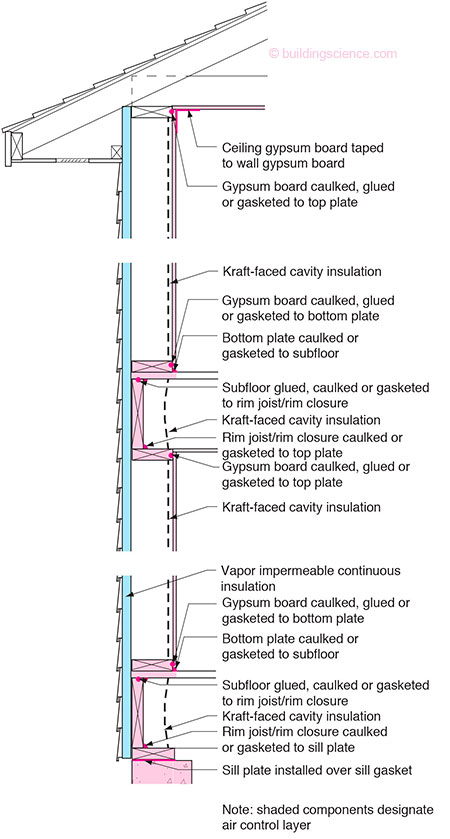

Let’s look at two wall assemblies with “double vapor barriers” that have powerful historical track records (Figure 7 and Figure 8). The difference between the two is that one uses polyethylene as both the air barrier and vapor barrier (in “Joe speak” this is would be the air control layer and the vapor control layer) and the other uses the interior gypsum board as the air barrier (air control layer) and the facing on fiberglass batt cavity insulation as the vapor barrier (vapor control layer).

Figure 7: Poly Air/Vapor Barrier (above left)—This assembly uses polyethylene as both the air barrier and vapor barrier (in “Joe speak” this is would be the air control layer and the vapor control layer).

Figure 8: Drywall Air Barrier (above right)—The interior gypsum board is the air barrier (air control layer) and the facing on fiberglass batt cavity insulation is the vapor barrier (vapor control layer).

Using the kraft facing (Photograph 4) on the fiberglass cavity insulation as the vapor control layer takes advantage of the change in vapor permeance of this layer as a function of relative humidity (Figure 9). Kraft-faced

insulations were the original “smart vapor barriers”.

Photograph 4: Kraft Faced Fiberglass Batts—The facing is the vapor control layer. Note that the Kraft facing does not function as an air barrier (air control layer).

Figure 9: Vapor Permeance vs Relative Humidity—Kraft faced insulations were the original “smart vapor barriers”. During the heating season most homes (and most buildings) have interior relative humidity in the 20 to 35 percent range. In this range the Kraft facing performs as a Class II vapor retarder. During the summer most homes (and most buildings) have interior relative humidity in the 60 percent and higher range causing the Kraft facing to “open” from a vapor resistance perspective.

During the heating season most homes (and most buildings) have interior relative humidity in the 20 to 35 percent range. In this range the kraft facing performs as a Class II vapor retarder. During the summer most homes (and most buildings) have interior relative humidity in the 60 percent and higher range causing the kraft facing to “open” from a vapor resistance perspective. We can accomplish the same thing with some paint systems and some plastic membranes (aka “smart vapor barriers”). With this approach we only have a “double vapor barrier” during the winter – we don’t have one during the summer.

Note that the kraft facing does not function as an air barrier (air control layer). This approach needs to be coupled with “fastidious” air sealing of the interior gypsum board (“the air drywall approach”). We were here earlier as well (BSI-084: Forty Years of Air Barriers—The Evolution of the Residential Air Barrier).

So where are we with all of this? Yes, double vapor barriers are counter-intuitive but they do work – within the limits noted above – especially the points about humidified and pressurized buildings and control of condensing surface temperatures6. Recall that we have been focusing on cold climates in this discussion. For the record I do not have heartburn with interior vapor barriers in cold climates. Nor should all of you. But I do have heartburn with interior vapor barriers in hot climates and mixed climates and pretty much any place with lots of air conditioning.

Footnotes:

- Semantics are important here. If you misname things you don’t understand things. This lower layer can be vapor open and the roof assembly would still function in the majority of applications but there is no way that this layer can be air leaky and function in the majority of applications.

- OK, OK, the upper membrane also has to be watertight. Yes, I know that is the point of having a roof. In making the upper membrane watertight you also make it airtight. The same folks who install the upper membrane also usually install the lower membrane and do it just as fastidiously. Note that “fastidiously” is the new “anal”. The vast majority of flat roofs don’t leak water and therefore the vast majority of flat roofs also don’t leak air – when they also have a lower membrane.

- Yeah, but what happens when they leak? They get wet, that’s what happens. And they can’t dry. So what happens? Well, you walk the roofs every couple of years and find if or where they are wet and leaking and take them apart and dry them and fix them and move on. We have been doing this longer than I have been alive and I remember when Elvis was thin and the Maple Leafs won Stanley Cups.

- I love the “roofs don’t count” comment from folks when you crush them with an obvious fact that destroys their argument. Apparently, the physics are different in roofs and walls. Actually, not, but the assemblies are somewhat different as we shall see.

- This is another place where field experience and field measurements disagree with most hygrothermal analysis if the air component is not included. See “BSI-089: WUFI—Barking Up the Wrong Tree?”.

- One final point, and this goes for all wall assemblies not just ones with double vapor barriers, don’t close them up when they are wet. Ah, without the poly on the inside the wall can dry to the inside you say. Do you seriously think covering up a wet wall with a paper-faced sheathing like drywall is a good idea?