Civilians seem to think that we have the technology to go into a space, do a test, and determine what is in the air. As simple as that sounds we can’t do it. We don’t have the technology.1 You cannot go into a space and ask a simple question such as what is in the air? There could be a million things in the air–literally. You have to ask a much more narrow question such as is “this” in the air? Or is “that” in the air? The trick is to know what to ask. For that you need a hypothesis.2

To be certain about what is in the air you have to ask about everything. That of course is impractical because of the gazillion things that you could test for. When someone says we tested the air and there was nothing in the air they are being less than forthcoming. What they are really saying is that we didn’t find what we tested for within the limits of accuracy of the test procedure we used. That is a whole lot different than saying there is nothing in the air. The only people who like air testing are people who make money doing air testing.

Saying you should never start with air testing gets you nowhere with civilians. I never win this argument. There is always some “expert” that comes in and does a bunch of air tests. I am the one usually stuck with having to explain what they mean. More precisely, I have to explain what they don’t mean.

Let’s start with some of the tests that are run and what they mean. Then we will get into other tests and what they don’t mean.

I don’t have a problem with measuring CO2—it is sometimes, not always, a pretty good surrogate for ventilation rates. I prefer to determine ventilation rates more directly, but I am a geek. What hypothesis are you testing with a CO2 test? Is the ventilation rate too low or too high according to ASHRAE Standard 62.1?

I also don’t have a problem with measuring temperature and relative humidity—I can tell a lot from measuring temperature and relative humidity. Again what is the hypothesis? Do I have a part load humidity control problem that could lead to mold?

At this point I typically stop with the testing. Why? Almost everything else is pretty much a waste of time. The most popular waste of time are tests for volatile organic compounds (“VOCs”).

VOC testing. I love the name. It sounds so technical, so Star Trek-ish. How does it work? You suck on air for about a minute and draw the air through magic powder (the sorbent) and send it off to a lab. The idea is that the powder absorbs “stuff” in the air. You then desorb the “stuff” and run it through a mass spectrometer/gas chromatograph to get a spectral “fingerprint.”3 You then compare the spectra of the “stuff” to a “library” of available spectra.

Think about this for a minute. You sample for about a minute. Is it a representative minute? Where do you sample for this minute? Let’s say you can deal with all of this minute stuff or you feel you can make something up that sounds semi-believable to get others to ignore the issues with this minute stuff. Now what?

Here is where it gets out of control. What is in the “library”? Depends on the lab. Folks tend to look at the “most common 40 spectra” which typically means the most common 40 in the lab library.4 So the typical voc test looks to see if those specific 40 things are in the air.

If your “stuffs” spectra are not in the labs top 40, too bad, you are out of luck. Maybe it’s close to one of the top 40? Does the lab say that it is close? Ah, it depends. If it is not close to your top 40 do you look farther? How do you look? Do you even know you should look? Sorry, looking further is not going to happen unless you pay, and pay and pay. You can ask NASA.5 But why look even in the first place? Or why look this way? More about that later.

So lets say that some of your “stuff” matches some of the “top 40.” What are the odds? High. Why? Well, if you selected the EPA’s BASE list as your comparison “stuff” you are going to find stuff because the whole point of that study was to look for stuff that you are likely to find.

Now you get to ask the question civilians ask all the time. Are the levels too high or too low? ou pretty much have nothing to go on. We don’t have acceptable or unacceptable levels for most of the stuff. Can BASE help us out? Nope, the study just said what the levels were, not whether they were too high or too low. Is BASE even representative? Sure, ask an easy question. Some folks say that it is, some folks say that it is not. What do I say? It was probably representative then, it is probably not representative now.

Oh, we have some Threshold Limit Values (TLV’s) for some occupational stuff. But that is occupational stuff. If you are factory worker and you are working with a particular chemical that we know a great deal about NIOSH probably has an exposure limit for that particular chemical. But, TLV’s only apply in factories (i.e. “occupational exposure”); they do not apply in office buildings and certainly not in houses.

I am an order of magnitude kind of a guy and I sometimes divide the occupational numbers by “ten” when pressed for an opinion for office and residential exposure. But this is an arbitrary guess on my part. There is no health data that I have to go on. Why not divide by a “hundred”? Some folks do. Are they more “right” than me? They seem to think so. The point is that we are “making this stuff up.” All of us.

So lets say you test for some VOCs and you get a “hit.” Lets even say that it is a pretty well known VOC that has a TLV associated with it. And lets say you divide the TLV by “ten” or a “hundred” or whatever strikes your fancy and your top 40 hit is above your own particular arbitrary “action level.” Now what? Where did it come from? Isn’t that the fundamental question?

The VOC test report from the expensive lab has big words that mean absolutely nothing because you don’t know where the stuff is coming from. How helpful is that? So what is the typical recommendation from one of these reports? Increase the ventilation rate. That will reduce the concentration. Aaragghh. Dilution is not the only solution to indoor pollution. We can’t ignore the effect of ventilation rates on energy and part load humidity. We can’t just turn up the crank and ventilate like crazy. Whatever happened to “source” control? Here is the rub. Source control only works if you know the source. Duh.

I have a completely different approach to this problem. Now there’s a surprise. In my experience contaminants are usually associated with materials breaking down. The breakdown products are typically gases and particulates that can get into the air. The most common “damage functions” are water, heat, ultra-violet radiation and ozone.6 Let’s put this information to use.

What is the hottest, wettest, most exposed to UV and ozone component of a building? The roof. Picture a sunny day in July, mid afternoon, and you are standing on a black EPDM membrane. What temperature is the membrane? Oh, 170 degrees F, give or take 10 degrees. Take a deep breath. What do you smell? The roof. You are smelling the VOCs that are being emitted as the roof breaks down due to the damage functions previously mentioned. Now, bend down and rub your hand over the surface of the room membrane. Little pieces of it come off. When these particles get into the air with the VOCs you have more contaminants. That is why it is always a good idea to put your buildings fresh air intake up on the roof so you can suck all of these VOCs and particulates right into the building and inject them into the breathing zone of the occupied space.

How hot do walls get? Depends on the cladding and the orientation; anywhere from 100 degrees F to 130 degrees F. Let’s install a dropped ceiling return plenum that is not isolated from the exterior walls so that we can suck these wall VOCs right into the building. You get the picture. Do walls get wet? Are they exposed to UV? Same pathway.

Now, lets play with Arrhenius. Every 10 degrees C doubles the off-gassing rate. Increase humidity and UV exposure and the same happens. It’s all exponential, it’s synergistic and it’s all bad. So things that are both hot and wet are really, really bad. Add UV and ozone and someone is going to have a very bad day.

So, most indoor air quality investigations for me start with looking for the wet spot, the hot spot, the spot that sees UV and ozone and asking if the “spot” is connected to the breathing zone of the occupants with a flow path and air pressure relationship—they do not start with VOC testing.7

Let’s look at a simple example of this approach at work. A retail space had odor complaints—a jewelry store on Newbury Street in Boston (Photograph 1). If you have ever had to deal with odor complaints you know how difficult they can become. People describe smells differently and certainly imprecisely. So, off I go to Newbury Street thinking hot, wet, UV and ozone. Well, I wasn’t thinking ozone; I was thinking hot, wet and UV.

Photograph 1: Jewelry Store on Newbury Street—No odor problems in neighboring retail spaces above, below or on either side.

Ozone only becomes a consideration if the first damage functions are off the table.

Inside the space there was a very, very faint odor that seemed to be both everywhere and nowhere. It kind of smelled like body odor, but that was my description. My female co-investigator had different adjectives. The store staff had even more different descriptors. The female staff had different views from the male staff. Typical. It was looking like it was going to be a long day. We all became adapted pretty quickly and then no one could smell anything.

It was pretty clear from looking at the space that we were not dealing with a water problem or UV. Nothing was wet, no humidity issues, no plumbing leaks and no solar aperture (no UV). This quick and dirty review took all of 15 minutes. So what is left? Hot spots.

The retail space had lots of display cabinets (Photograph 2) each with a light (Photograph 3). The individual lights generated heat—enough to warm each case compartment to about 140 degrees—a bunch of hot spots by anyone’s standard. So now I have a hypothesis. I bet the lights are generating enough heat to cause the cabinetry to smell. The cabinetry was some kind of “was-wood-once” composite with a “who-knows-what” finish.

Photograph 2: Retail Space—Long, narrow space with lots of display cabinets and lots of jewelry. Hold on to your wallet.

Photograph 3: Display Cabinets—Each cabinet “compartment” has a display light. The individual lights generate heat—enough to warm each case compartment to about 140 degrees. The working hypothesis is that the lights generate enough heat to cause the cabinetry to smell. The cabinetry is some kind of “was-wood-once” composite with a “who-knows-what” finish.

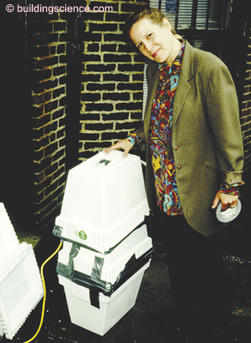

Time to test the hypothesis. Being a Canadian I never go anywhere without beer coolers and duct tape—it really is a cultural thing. This allows me to construct a portable environmental chamber in the parking lot in the rear of the store (Photograph 4). The environmental chamber has a “trouble light” inside of it to create heat. A portion of the cabinetry was disassembled in placed into the chamber and heated to around 140 degrees. This got the cabinetry to “stink.” We were able to recreate the reported odor inside the chamber (Photograph 5).

Photograph 4: Portable Site Constructed Environmental Chamber—Duct tape holds together some foam coolers containing a light bulb attached to an extension cord. Disassembled cabinetry is placed inside the chamber and heated to the operating temperature of the cabinets.

Photograph 5: Portable Human Mass Spectrometer—“Honey, does it smell in there the same as in there?” “Um, can you ignore the smell of the heated duct tape and foam cooler while you are sniffing?” Try getting a mass spectrometer to do what a human female can do: cancel out odors and describe them accurately at a parts per billion sensitivity—of course it might be easier to live with a mass spectrometer.

Now what? Source control. Getting rid of the cabinets would work but would be expensive. Rewiring the lights and replacing with LED’s would work but would also be expensive (besides, at the time, this technology was not available to us). The solution we chose was to depressurize the cabinetry relative to the retail space using an exhaust fan vented to the outside. We drilled holes in the individual display “chambers” connecting them to one another creating a single “pressure field.” Each bank of cabinets got its own fan.

We regularly store hazardous chemicals in laboratories in cabinets maintained under a negative pressure—we used the same approach here. After all, jewelry is hazardous to the pocket book.

How did we know the approach worked? The odor problems disappeared. But we never identified the specific “thing” that caused the odor. So? Who cares? The problem is gone. Well, it could have been bad stuff that caused health problems. Sheesh. How are you going to prove that? Ok, just for fun, let’s go down that road a little bit.

Let’s say that my client had this uncontrollable desire to spend more money to prove or disprove a health problem how would I have helped him in his cause? I would have sent a sample of the cabinetry to a lab and got the lab to heat the sample to drive off some VOCs and then do a mass-spec on the VOCs that were driven off. I would then collect an air sample in the retail space and do a mass-spec on the air sample. I would then compare the two spectra’s. The question to ask is a very basic one: is this the same as this? That is very different from “what is this?” I would then try to stop. What we will have done to this point is nothing more than a more expensive version of my beer cooler environmental chamber test.

Of course my client, wanting to spend more money is going to want to know the answer to “what is this?” Now what? Go to NASA and any other database available and try to find a match. Good luck. Let’s say you are now lucky and you get a match. What are the odds that NIOSH has a TLV associated with it? Hah. If so, divide by 10 or a 100 and try to find someone to say it is dangerous or not dangerous. If there is no TLV the approach also pretty much the same: try to find someone to say that it is dangerous or not dangerous. And for those of you who are still interested in playing this game: Good luck getting past Daubert.8

Joe’s Hard Lessons Learned and Short Incomplete List of Things To Do To

Stay Out of Trouble

If it smells bad it is probably bad.

If it smells at all it is probably bad.

Not everything that is bad smells.

Not everything smells when you decide to smell it.

Vent combustion sources.

Don’t suck on the ground—especially if you poison the ground.

Don’t do stupid things in your building.

Construct a tight enclosure to keep bad things out and good things in.

Keep things from getting wet, hot or exposed to UV— those that do—isolate them from the occupants.

Control indoor humidity.

Don’t build your building out of stinky things.

Don’t put stinky things in your building.

If you have to have stinky things or stinky places in your building, suck on them.

Bathrooms and kitchens are stinky, so are elevator shafts and trash chutes.

Keep things clean. A messy space is an unhealthy space.

Bugs and critters like food and water. Deny them the food and water. Be cruel.

Filter for people not just for equipment.

Ventilate for people, not for the building—source control will handle the building.

Footnotes:

This is not the Six Million Dollar Man—where is Lee Majors when you need him?

The fingerprint analogy now sucks in the CSI junkies. CSI is the current societal source of science information since Star Trek went off the air. It’s certainly not the educational system. We no longer teach anything useful in school like science or basic physics. But we do teach the kids how to feel good about themselves while they are unable to function in the modern world.

According to whom? Usually whatever 40 spectra the lab has handy, or 30 or 20... That really annoys me—the list is usually completely arbitrary and capricious. Now, some folks are a little bit more logical and look at the 40 VOCs that were sampled by the EPA in their BASE study a decade ago to at least look at some kind of a benchmark. That sounds pretty reasonable. Except for the next part. Who decided on the stuff the EPA tested for? Well, the best I can figure the EPA tested for stuff you would expect to find. So they looked for stuff that they expected to find and, yes, you guessed it, they found it. What about stuff that you wouldn’t expect to find? Nobody looked. With respect to air testing you have to already know what you are looking for before you find it. Because if you don’t already know, the odds of finding something useful are against you.

NASA has the most comprehensive spectra data set of anyone. When they first started sealing folks in aluminum capsules on the top of rockets NASA found that stuff off-gassed from the stuff inside the space capsules and affected the ability of the astronauts to function. The astronauts got “stoned” on the VOCs. NASA tested everything that went into a space capsule for off gassing and over time developed an impressive database of “stuff.” NASA discovered “source control” before anyone else. Dilution was not the solution to indoor pollution in the vacuum of outer space. Standard 62 committees take note – sometimes it is rocket science.

When we design buildings for “sensitive clients” we typically put material samples in a bell jar and put them outside in the sun for a couple of days and let the clients “sniff” them. We repeat the process with a little bit of water in the jar. If they don’t bother the client, they go in the building. Much better than trying to get anything useful from a MSDS sheet.

Actually, they start with me playing the odds. In my almost three decades of doing this I typically find that 50 percent of building complaints are because the building space is too hot, too cold, too wet, too dry or way too under-ventilated. These “first” 50 percent-ers are pretty easy to check out. The next 20 percent are humidity or moisture problems. And the 15 percent after that are due to stupid maintenance or cleaning practices. So 85 percent of building complaints typically are due to comfort, under-ventilation, poor maintenance and cleaning practices, and moisture problems. None of these issues require any type of sophisticated testing or analysis to diagnose or resolve. The last 15 percent have no obvious pattern and can be a real pain to deal with. I start on the last 15 percent after I have taken the other 85 percent off the table. One of the places to start dealing with issues in the last 15 percent category is the wet spot, hot spot, the spot that see UV and ozone approach.

US Supreme Court opinion, Daubert v. Merrell Dow (1993), the “junk science” test for the admissibility of “scientific evidence.”