Condensation within walls during cold weather is a common performance problem. Most such condensation is due to air leakage, not diffusion. Although air barrier and vapor control layers can reduce the quantity and occurrence of condensation due to both mechanisms, the use of exterior insulation (even if that insulation is a vapor barrier and/or air barrier) can warm sensitive surfaces within a wall and thereby eliminate or reduce condensation risks. This digest provides the background for designers to select the insulation levels need to reach specific levels of condensation control.

Cold-weather condensation is primarily the result of outward air leakage. Diffusion usually does not move sufficient quantities of water vapor fast enough to generate a problem. To control damaging condensation inside enclosure walls and roofs, air barriers are used to stop airflow and vapor control layers (vapor diffusion retarders or barriers) are used to limit diffusion flow.

Air leaking outward through the enclosure wall in cold weather will contact the back of the sheathing in framed walls. This condensation can accumulate as frost in cold weather, and subsequently cause “leaks” when the frost thaws and liquid water drains down, or cause rot if the moisture does not dry quickly upon the return of warmer and sunnier weather.

In walls with sufficient exterior insulation, the dewpoint temperature of the interior air will be below the temperature of the back of sheathing: therefore condensation due to air leakage cannot occur within the studspace. If an assembly is shown by calculation to be safe against air leakage condensation (using the method described below), then diffusion condensation cannot occur, even if absolutely no vapor resistance is provided inside of the sheathing (i.e., no vapor barrier or other control layer), and even if the sheathing is a vapor barrier (such as foil-faced insulations).

The occurrence of interstitial condensation is in itself not usually an indicator of a design flaw: if air leakage condensation occurs only under extreme conditions (e.g., the 99% design condition listed in the ASHRAE Handbook of Fundamentals or other sources), air leakage during the many hours following this rare event will actually dry the wall when sheathing temperatures rise above the interior dewpoint. Hence, the choice of conditions for the analysis is very important. Although data for outdoor air temperatures is readily available, even north-facing walls will have some exposure to diffuse solar radiation, which will warm the cladding (and hence the wall), above the outdoor air temperature for many hours of cold winter months.

It is difficult to choose the exterior temperature to design for, since any level of condensation protection can be chosen by the analyst, from none to total. For materials with some resistance to moisture (e.g., glass-mat faced exterior-grade gypsum sheathing is quite resistant to moisture), and/or with some capacity to safely store moisture (e.g., plywood and OSB sheathing), a much less stringent design criteria is justified than for materials with no storage (e.g., foil-faced insulation) or high moisture sensitivity (paper-faced gypsum). Some judgement is therefore called for. The average winter (average of the coldest three months) temperature is considered a reasonably safe value (and is readily available). For especially high performance systems (or walls that are highly sensitive to moisture damage), a more conservative value can be chosen, such as the coldest month, 10°F/6 °C less than the monthly average or 9 °C/15°F above the 99% design temperature.

The interior conditions within a building during cold weather are critical variables in understanding the risk of condensation, and must be known if predictions and calculations are to be made. Interior temperatures are often in the 70 °F / 21 °C range, but relative humidity levels, and thus air moisture content, can vary significantly. In most office, school, and retail occupancies, ventilation rates are high enough that the RH during winter months is in the range of 25 to 35%. In some residential occupancy, the interior moisture generation is higher and exterior air ventilation rate lower than commercial occupancies, and hence the RH will often be higher. In special occupancies, such as swimming pools, both the interior temperature and relative humidity levels will be higher (78°F/25 °C and 60%RH), resulting in very high absolute humidity levels.

The moisture content of the exterior air always drops at very cold conditions as the maximum air moisture content drops. As outdoor conditions become colder, the interior RH drops because interior moisture is diluted by increasingly dry exterior air. This effect provides some protection against condensation, as the coldest week of the year is likely to coincide with some of the lowest interior humidity levels.1

The interior moisture content is usually defined by a combination of temperature and relative humidity. More direct metrics are absolute humidity or humidity ratio, usually expressed in grams of water per kg of dry air (or grains of water per pound of dry air). However, practically speaking, the most useful measure is the dewpoint temperature of the interior air.

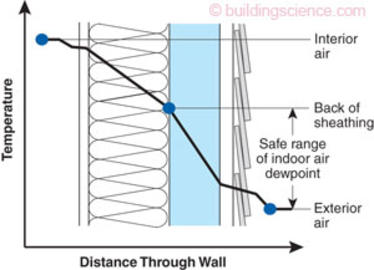

Given an agreed upon set of interior and exterior design conditions, it is easy to calculate the level of insulation required outboard of the framing space or sheathing to control air leakage condensation. Condensation can be avoided by ensuring the temperature at the back of the sheathing is warmer than the interior air dewpoint temperature. If one assumes that interior finishes and exterior cladding have little thermal resistance (almost always a reasonable assumption) then the back of the sheathing temperature can be found from:

Tback of sheathing = Tinterior – (Tinterior-Texterior) * Rbatt/Rtotal

This concept is shown graphically in Figure 1. It should be clear from this analysis that any amount of insulated sheathing on the exterior of framed structures will provide better protection against air leakage condensation in cold weather than no exterior insulation. For a fixed R-value of exterior insulation, the risk of condensation will also drop as the interior insulation R-value drops. Thus, if there is no insulation in the stud bay at all (reducing the inboard R-value to that of the interior finish and empty studspace only, approximately R-2) almost any reasonable level of exterior insulation R-value provides complete protection from air leakage condensation and diffusion during cold weather.

Figure 1: Insulating sheathing reducing air leakage condensation

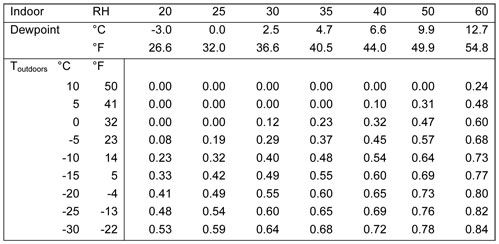

Table 1 provides the level of insulation (sheathing plus airspace and cladding) that should be provided outside of a studspace filled with air permeable insulation (i.e., batt or blown fibrous insulation) to prevent cold-weather exfiltration condensation. It can be seen that mild temperatures and dry interior air require little exterior insulation to control condensation, whereas a museum maintained at 50% in Fairbanks, Alaska or Yellowknife, Northwest Territories should have essentially all of the insulation on the exterior.

More specifically, consider a house in Toronto. We will choose a winter average temperature as a design criteria and a design interior RH of 35%. The December, January, and February temperatures for Toronto are -1.9, -5.2, and -4.4 °C respectively, leading to a wintertime average temperature in Toronto of -3.8 °C (25 °F). From the table, the interior dewpoint can be read as being approximately 40°F/5°C, and therefore somewhat less than 37% of the total insulation value of the wall should be on the exterior in the form of insulating sheathing, air gaps, and cladding.

Targeting a total enclosure R-value of 20 would require 0.37 * 20 = of the total, or R-7.5 on the exterior to avoid condensation if air leakage occurred. This leaves R-12.5 on the inside, which could be comprised of an R-12 batt and interior finish. The exterior cladding and airspace add some R-value on the exterior, but these can be conservatively ignored. This solution, R-12 batts between 2x4 studs with R-7.5 exterior insulation sheathing, is very safe against air leakage condensation for this Toronto example. If R-30 were the target, 0.37*30= R-11 of exterior sheathing and R-19 stud space insulation would be one solution. More detailed calculations including the resistance of wood cladding and an air gap, and properly interpolating the results between an outdoor temperature of 0 and 5 °C show that sheathing insulating value of R-5 over an R-12 batt will control condensation as well.

Table 1: Ratio of exterior-interior insulation to control air leakage condensation

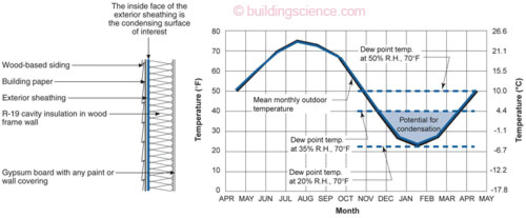

This type of simple analysis can be conducted on a monthly basis and plotted to help visualize the condensation risk. An example of a wood-framed wall in the Chicago climate is shown in Figure 2.

Figure 2: A monthly analysis of the condensation potential of two walls in the Chicago climate

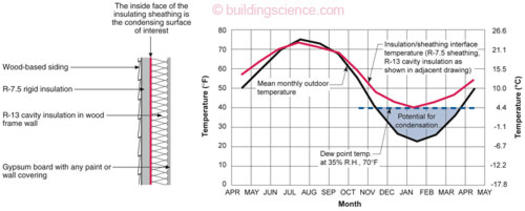

Adding more air-permeable insulation to the stud bay (e.g., if a 6” stud is required structurally, a well-intentioned contractor may fill the stud cavity with an R-20 batt) will of course lower the safety against condensation—dangerously in this case. Adding significantly more insulation to the exterior (going from R-7.5 to R-15 for example), will significantly reduce risk. Regardless of the wall assembly, exterior climate and indoor humidity, the same trends will always hold: adding insulation value to the exterior decreases condensation risk, adding air-permeable insulation value to the stud space increases the risk of condensation.

It is important to note that the R-values used on the analysis are the center of stud bay R-values, as condensation will occur at the coldest part of the sheathing, and this will be between the studs. Hence, although the actual overall wall R-value of an R-13 batt between 3.5” steel studs at 16” o.c. (90 mm studs at 400 mm spacings) will be around R-5 due to thermal bridging at the studs, the batts will be effective over the middle of each stud bay. Therefore, condensation fed by air leakage or diffusion will first begin to occur between the studs, and in most cases, condensation will never occur on the studs.

Given the results of the condensation analysis method described, and the knowledge that steel studs with insulated stud bays provide overall wall R-values of only around R-5 to R-7, it is generally recommended that all of the desired insulation value be placed on the exterior of such light-gauge steel enclosures.

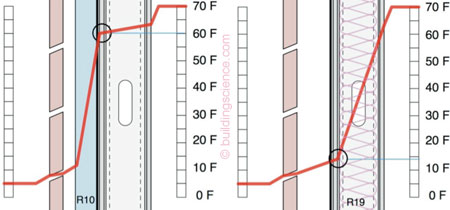

Consider the two steel stud framed wall designs shown in Figure 3 during a period of cold weather. Applying R-10 (RSI 1.76) of insulating sheathing (continuous insulation of any type) on the exterior of the framing will result in a sheathing temperature of above 60 °F (15 °C) everywhere within the stud space, including at the sheathing, during a night when the outdoor temperature drops to 4 °F (-15 °C). Hence, condensation is practically impossible within the stud space or on the sheathing (typically one of the moisture sensitive components in the assembly). This is true even if air leakage occurs, as all the surfaces are above the dew point temperature of the interior air.2 If R-19 (RSI3.5) insulation is placed between the framing, the sheathing temperature will be approximately 10°F (-12 °C), well below the temperature at which condensation can occur. The latter design relies on perfect air barriers (air impermeable spray foams are one solution) to avoid air leakage condensation. If the cavity fill is highly vapour permeable (e.g., fiberglass, rockwool, or open cell, half-pound density foam), a vapour control layer (Class II) is also necessary to reliably manage vapor diffusion.

Figure 3: Insulating sheathing as condensation control measure. Continuous exterior insulation on the left, framing cavity insulation on the right. The red line plots the temperature through the two assemblies on a 4°F (-15°C) night. Blue line shows back side of sheathing temperature.

The design with all of its heat flow control as a continuous layer of insulation on the exterior can perform very well even if air leakage occurs, and requires no special care in the selection of interior layers for vapour control. It should also be recalled that the wall with only exterior insulation would have an overall R-value of around R-12 (RSI2.1), whereas the wall with framing cavity insulation would have an overall R-value of between R-6 to R-8 (RSI 1.1 to 1.4) (depending on floor and wall framing intersection details and the type of cladding).

In many situations, a hybrid of exterior insulating sheathing and stud cavity insulation may be considered. Figure 4 plots the temperature through two hybrid solutions under the same conditions considered previously. Installing R-12 (RSI2.1) of insulation within the stud space will improve the thermal performance of the wall by about R-6 (increasing the assembly to a total R-value of over 16 / RSI2.8), but will reduce the sheathing temperature to 35 °F (2 °C) on this cold night. In many commercial occupancies, the interior dew point temperature will fall below 35 °F (2 °C) during cold weather and so condensation is unlikely, but far from impossible. If the R-12 were added in the form of air impermeable spray insulation (e.g. SPF), air could not practically reach the sheathing and there would be no risk of air-leakage condensation.

R-17/RSI 3.0 Total R-18/RSI 3.2 Total

Figure 4: Hybrid insulation approach—Although riskier, particularly in cold climates and higher interior humidities, hybrid walls offer slightly higher R-value and can be moisture-safe in many applications. Note that the ratio of exterior insulation value to the framing cavity R-value defines the cold-weather condensation risk.

If R-19 (RSI3.5) of air permeable insulation was added to the stud space, the R-value of the assembly would rise by about R-7 over the empty studspace scenario: that is, almost 2/3 of the insulation value of the R-19 batt would still be lost. However the sheathing temperature would drop below 30 °F (-1 °C) and the risk of condensation would be higher. The relatively small increase in heat flow control provided by the batt insulation is achieved at the cost of much increased condensation risk.

The same solutions that avoid air-leakage condensation will also completely solve cold-weather condensation due to vapor diffusion even if the exterior sheathing is a perfect vapor barrier (e.g., foil-faced or plastic faced insulation boards). If the selected sheathing layers (including structural sheathing, water control, and insulation) are somewhat vapor permeable (such as expanded polystyrene over building paper and plywood), less R-value can be used and diffusion condensation will still be controlled (because much of the vapor that diffuses or leaks with air into the stud bay will pass harmlessly through to the outside by diffusion). If the sheathing layers are very vapor permeable (e.g., rockwool over fiberboard or gypsum sheathing, and housewrap) then very little insulation value is required outboard of the stud bay. However, while these permeable layers can essentially eliminate vapor diffusion condensation risks with lower exterior sheathing R-values, the risk of air leakage condensation does not drop as much: air leakage may still deliver more water vapor to the back of the sheathing than can be removed by diffusion through the sheathing, and hence condensation could still occur and accumulate.

For important projects or situations in which the design team has little historical experience, investigation using widely available computer models such as WUFI-ORNL would be prudent if the necessary time and skills are available.

Footnotes

The correlation of indoor humidity levels and outdoor temperature would be much more direct if not for the moisture storage capacity of the building fabric, and the changing moisture production rates within a building. Sharp sudden drops in outdoor temperature are much more likely to result in condensation because the building stores a higher interior moisture level. If the temperature outdoor slowly drops over a period of days, the building interior slowly becomes drier as cold outdoor air enters.

This conclusion is valid even for high humidity interior environments, such as museums, as 70°F/50%RH air has a dew point of about 50 °F/10°C. Only through-fasteners such as screws, brick ties and roof screws would be at risk in such high RH environments. Swimming pools may have dew points exceeding 60°F/15°C and hence would require more R-value on the exterior to avoid interstitial condensation in cold climates.