We looked at exterior spray foam previously (BSI-048: “Exterior Spray Foam”, April 2011). Exterior spray foam typically is used in commercial applications. Most residential applications use interior spray foam. We are going to look at interior spray foam and focus on residential applications.

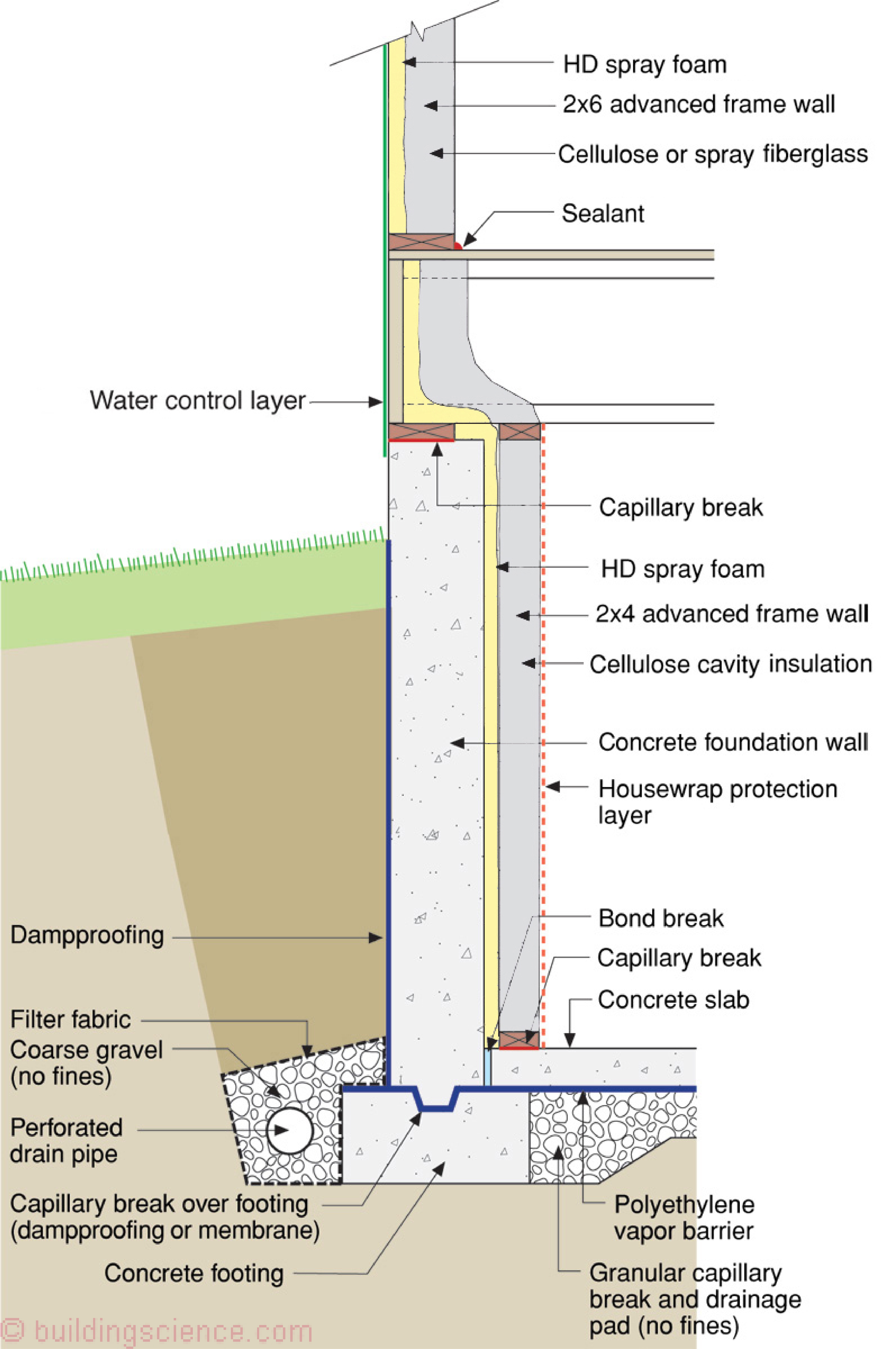

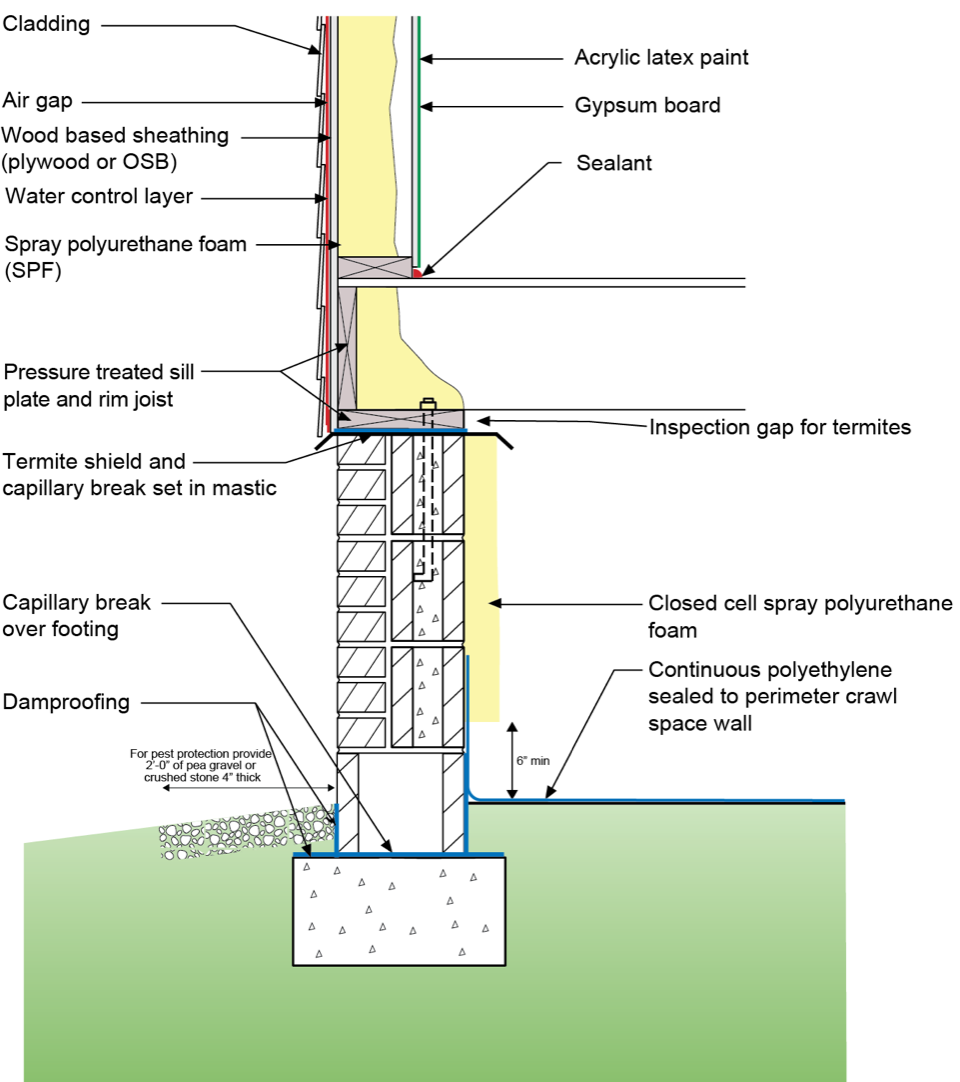

Houses are environmental separators – they keep the outside out and the inside in. Houses have walls, roofs and foundations that each have to be connected to each other (Figure 1). To function as environmental separators the walls, roofs and foundations have to be able to handle water, air, vapor and heat. How they handle water, air, vapor and heat depends on the materials used and the design. Spray foam is unique in that it has the ability to handle all four. However, most typical residential applications do not require spray foam to handle all four – residential water control (rainwater and groundwater) is typically handled by exterior water control layers – not spray foam. We are going to look at spray foam in residential walls, roofs and foundations installed to interior of the exterior water control layer.

Figure 1: Houses have walls, roofs and foundations that each have to be connected to each other providing continuity of the water control layer, air control layer, vapor control layer and thermal control layer.

Walls

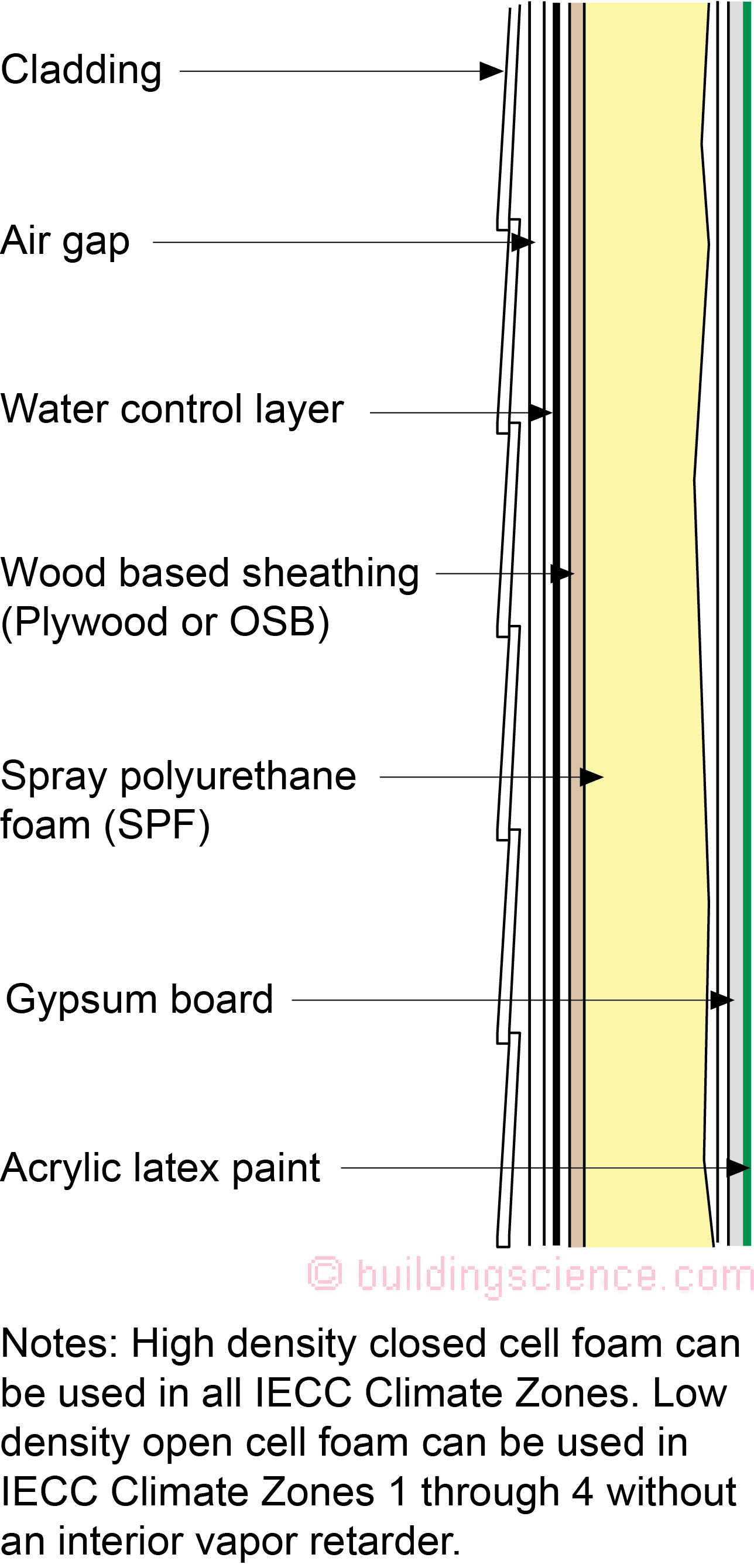

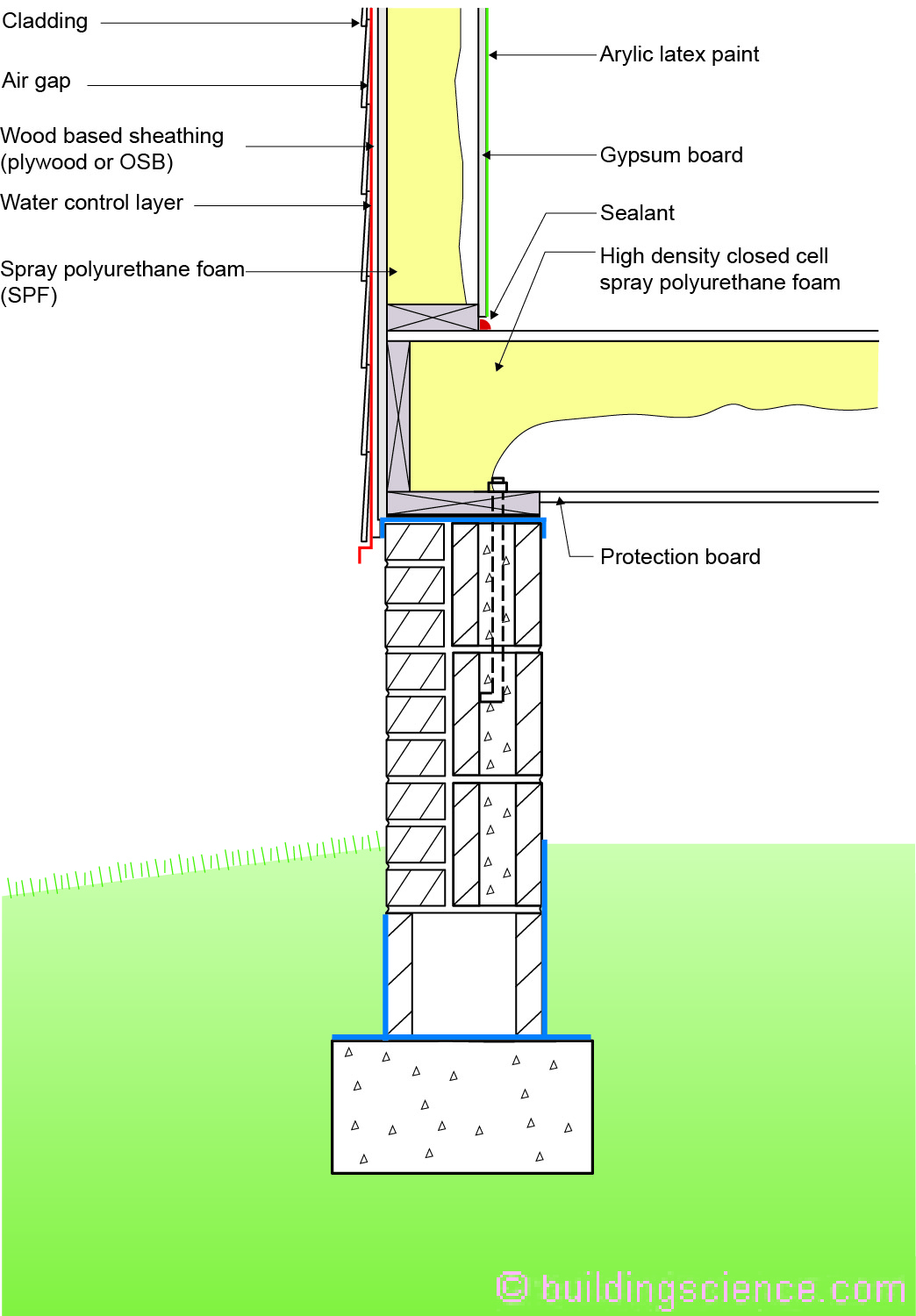

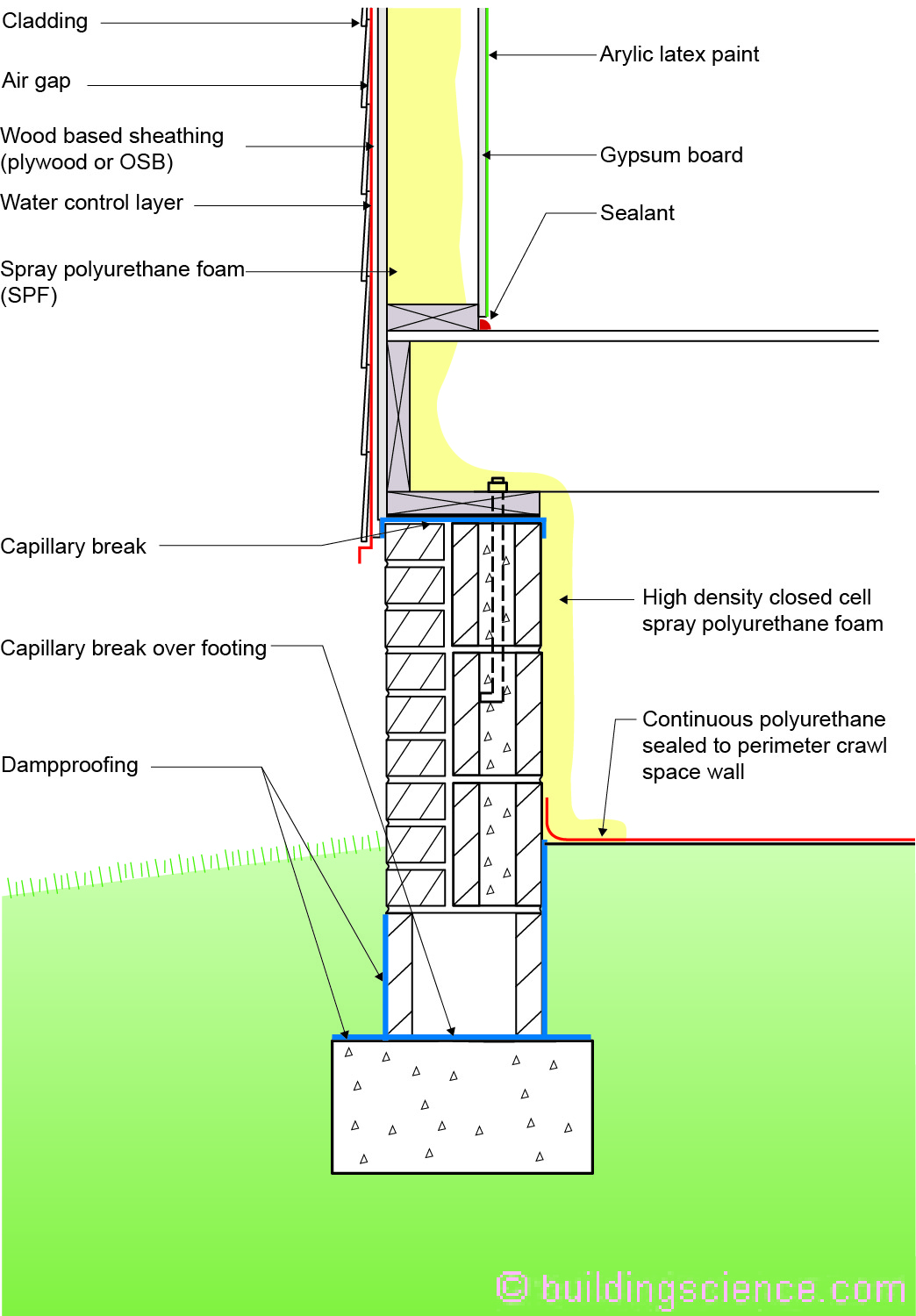

The most common residential wall is a wood frame wall with wood-based sheathing. The wood-based sheathing typically has a water control layer installed on its exterior surface. A cladding is installed over this water control layer. An air gap is provided between the cladding and the water control layer to provide drainage of rainwater that penetrates the cladding and thereby controlling hydrostatic pressure. The cavity insulation can be low density open cell or high density closed cell spray foam[1]. Both foam types work in most climates. As long as spray foam is sprayed to the minimum depth classified as an air impermeable insulation, the foam does not need to completely fill the cavity. Of course, the minimum code requirement for thermal resistance still has to be met.

In the International Energy Conservation Code (IECC) Climate Zones 6 and higher, high density closed cell spray foam provides additional condensation control and will qualify as a Class II vapor retarder at a thickness greater than 1.5 inches (38 mm). Low density open cell spray foam can be utilized with an interior vapor retarder to control condensation – the typical interior vapor retarder in such an application is a vapor retarder paint coating applied to the interior surface of the wall gypsum board lining.

High density closed cell insulation is preferred in cold climates and meets the code requirements for both condensation control for air impermeable insulation and acts as a code prescribed Class II vapor retarder as specified in the International Residential Code (IRC) section R702.7 for IECC Climate Zones 5 – 8 and Marine 4. The interior lining is gypsum board with acrylic latex paint (Figure 2). The water control layer can be a house wrap, a building paper, a fluid applied membrane, a fully adhered synthetic membrane, or it can be a coating that comes on the wood-based sheathing from the manufacturer. The water control layer in this type of wall should not be a vapor barrier – it should be semi vapor permeable – greater than 5 perms. Interior vapor barrier coatings on the gypsum board such as vinyl wallcoverings, oil or alkyd paints should be avoided. The air gap behind the cladding can be provided by using a textured house wrap, a drainage mat or furring strips at least 3/16 inch thick. Roll sill gasket material is an effective furring strip.

Figure 2: Common residential wall using spray polyurethane foam (SPF).

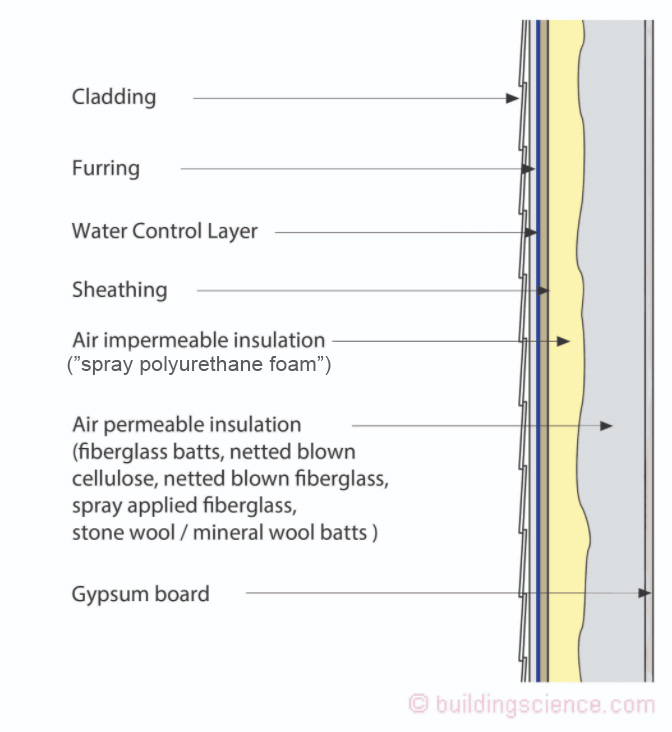

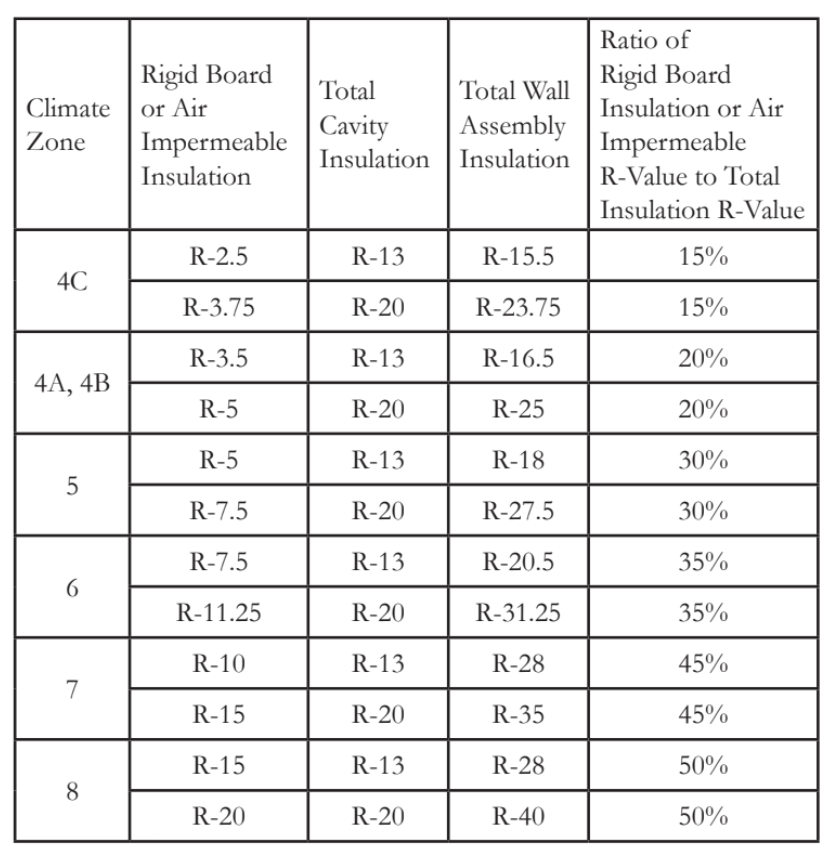

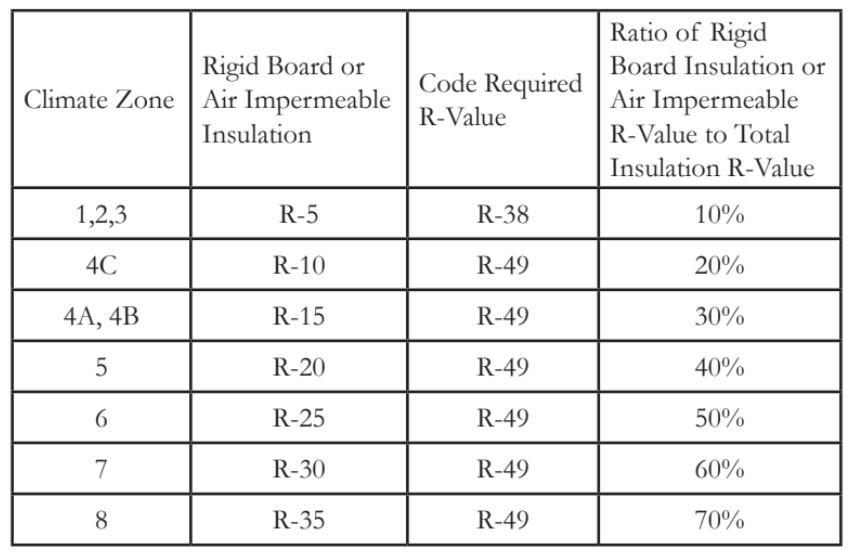

Hybrid walls can be constructed where spray polyurethane foam can be used in conjunction with other cavity insulations such as fiberglass and cellulose. Figure 3 is a variation of Figure 2 where high density closed cell spray polyurethane foam is installed on the interior surface of the wood-based sheathing. The thickness or thermal resistance of the spray foam is specified by the International Residential Code (IRC) based on climate zone and thickness of the wall framing (Table 1). Note that we were here previously as well (BSI-100: “Hybrid Assemblies”, October 2017).

Figure 3: Hybrid walls can be constructed where spray polyurethane foam can be used in conjunction with other cavity insulations such as fiberglass and cellulose.

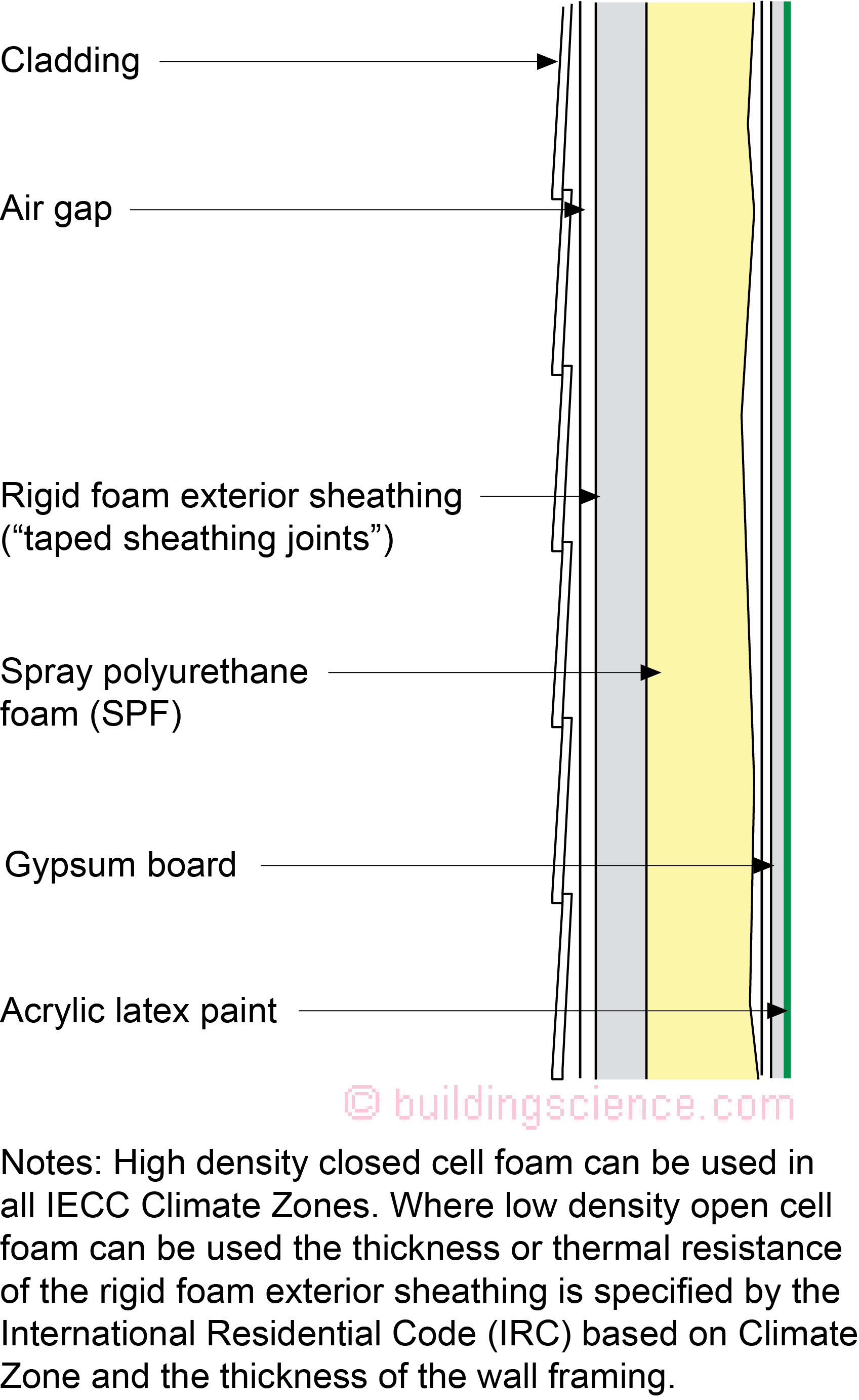

Spray polyurethane foam can also be applied to the interior of rigid foam exterior sheathings such as foil faced isocyanurates and extruded polystyrene (XPS). In these assemblies the water control layer is typically the taped joints of the exterior rigid insulation. The cavity insulation can be low density open cell or high density closed cell spray foam (Figure 4). Where low density open cell spray foam is used, the thickness or thermal resistance of the rigid foam exterior sheathing is specified by the International Residential Code (IRC) based on climate zone and thickness of the wall framing (Table 1).

Figure 4: Spray polyurethane foam can also be applied to the interior of rigid foam exterior sheathings such as foil faced isocyanurates and extruded polystyrene (XPS). In these assemblies the water control layer is typically the taped joints of the exterior rigid insulation. The cavity insulation can be low density open cell or high density closed cell spray foam.

Insulation for Condensation Control*

Table 1 *Adapted from Table R 702.1 2018 International Residential Code

Roofs

The most common residential roof is an attic that is wood framed, typically using trusses. It can be either an unvented conditioned attic or a vented unconditioned attic. Unvented conditioned attics are common in warm climates where basement construction is not common. The absence of basements typically results in mechanical systems and ductwork being located in attic spaces. Locating mechanical systems and ductwork in vented unconditioned attic spaces is a large thermal penalty, and in hot humid and mixed humid climates results in significant condensation issues. Vented unconditioned attics are common in cold climates where basement construction is typical. Mechanical systems and ductwork in cold climates are typically located in basements and interior floor framing rather than in attics, avoiding associated large thermal penalties.

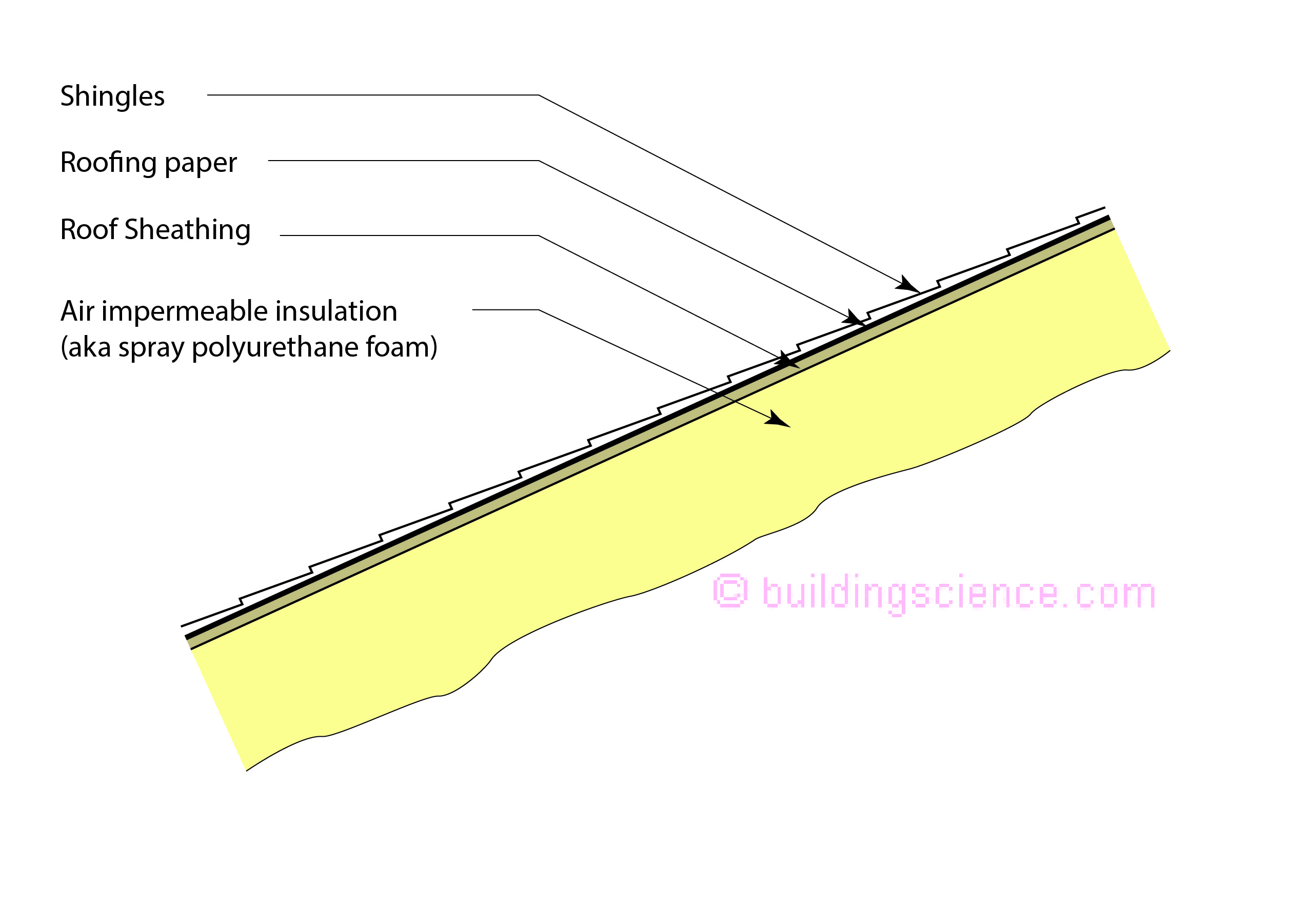

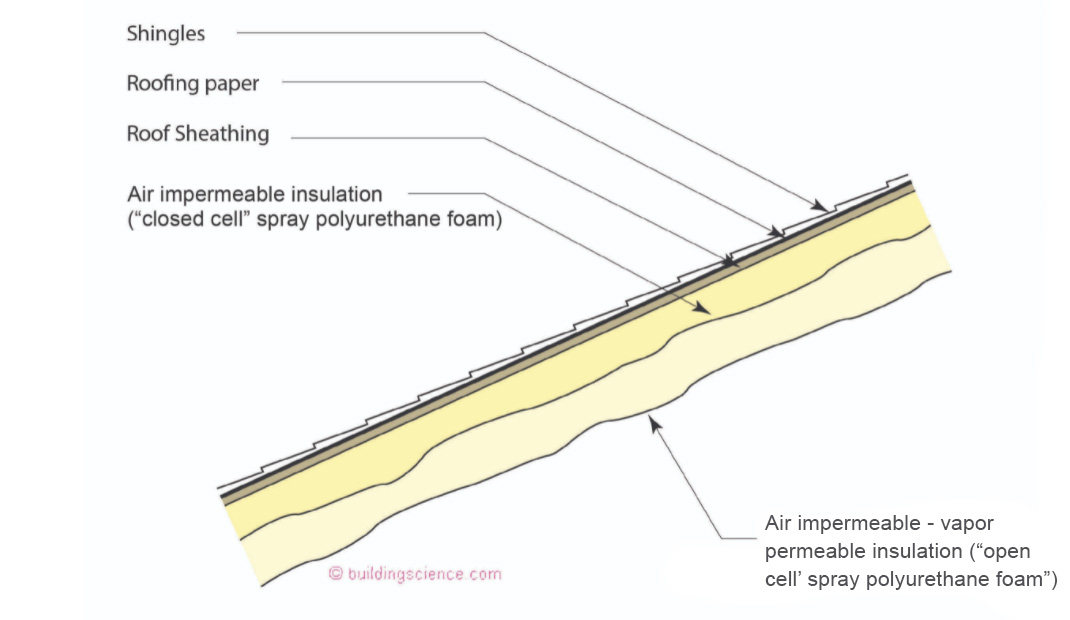

Unvented conditioned attics can be constructed by installing low density open cell or high density closed cell spray foam directly to the underside of the roof deck (Figure 5). Both foam types work in most climates. In IECC Climate Zones 5 and higher only high density closed cell spray foam should be used. The reason is that it is difficult and impractical to install an effective vapor control layer to the surface of low-density open cell spray foam. Vapor retarder paint coatings have had some limited success. Note the words “limited success”.

Figure 5: Unvented conditioned attics can be constructed by installing low density open cell or high density closed cell spray foam directly to the underside of the roof deck.

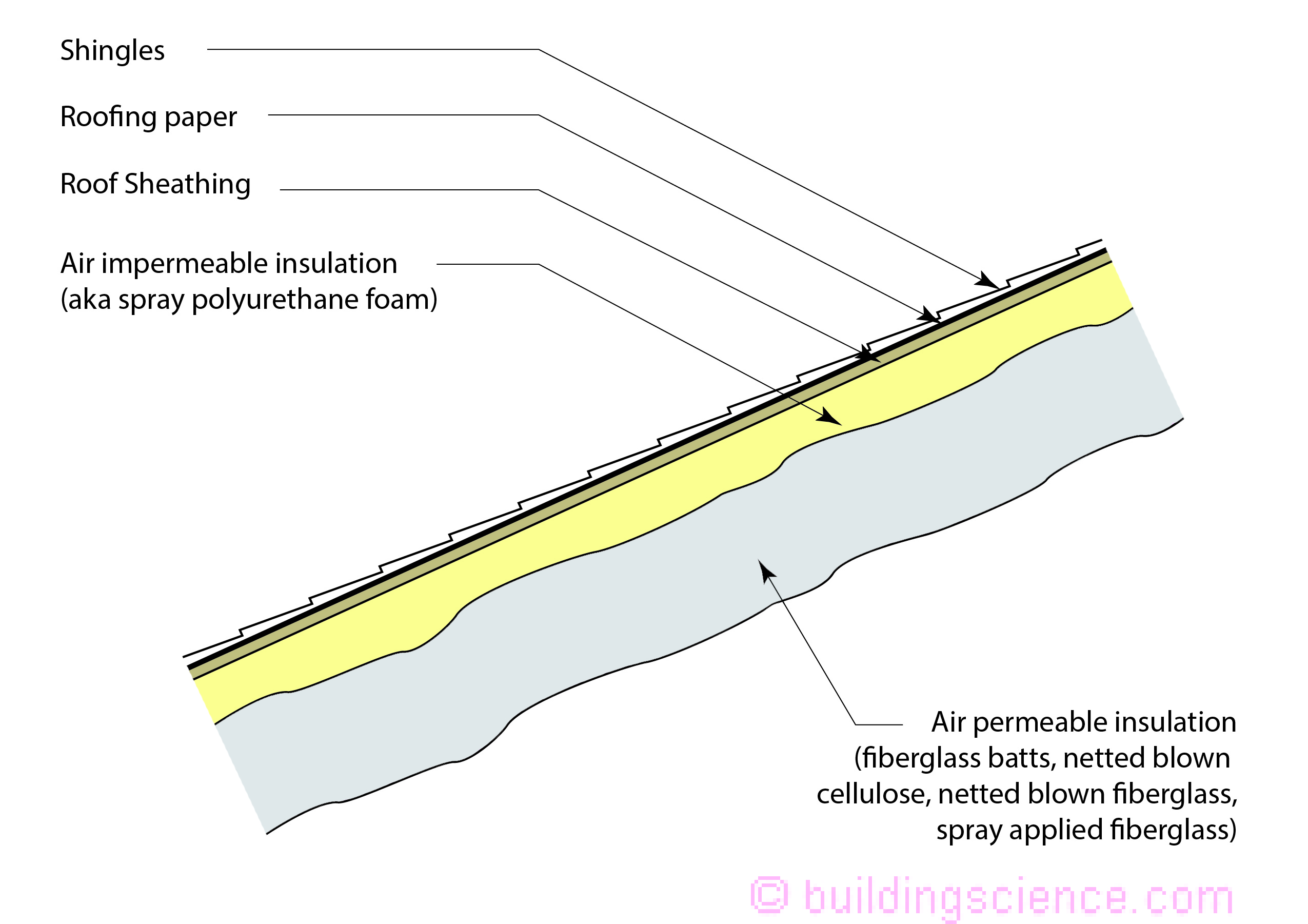

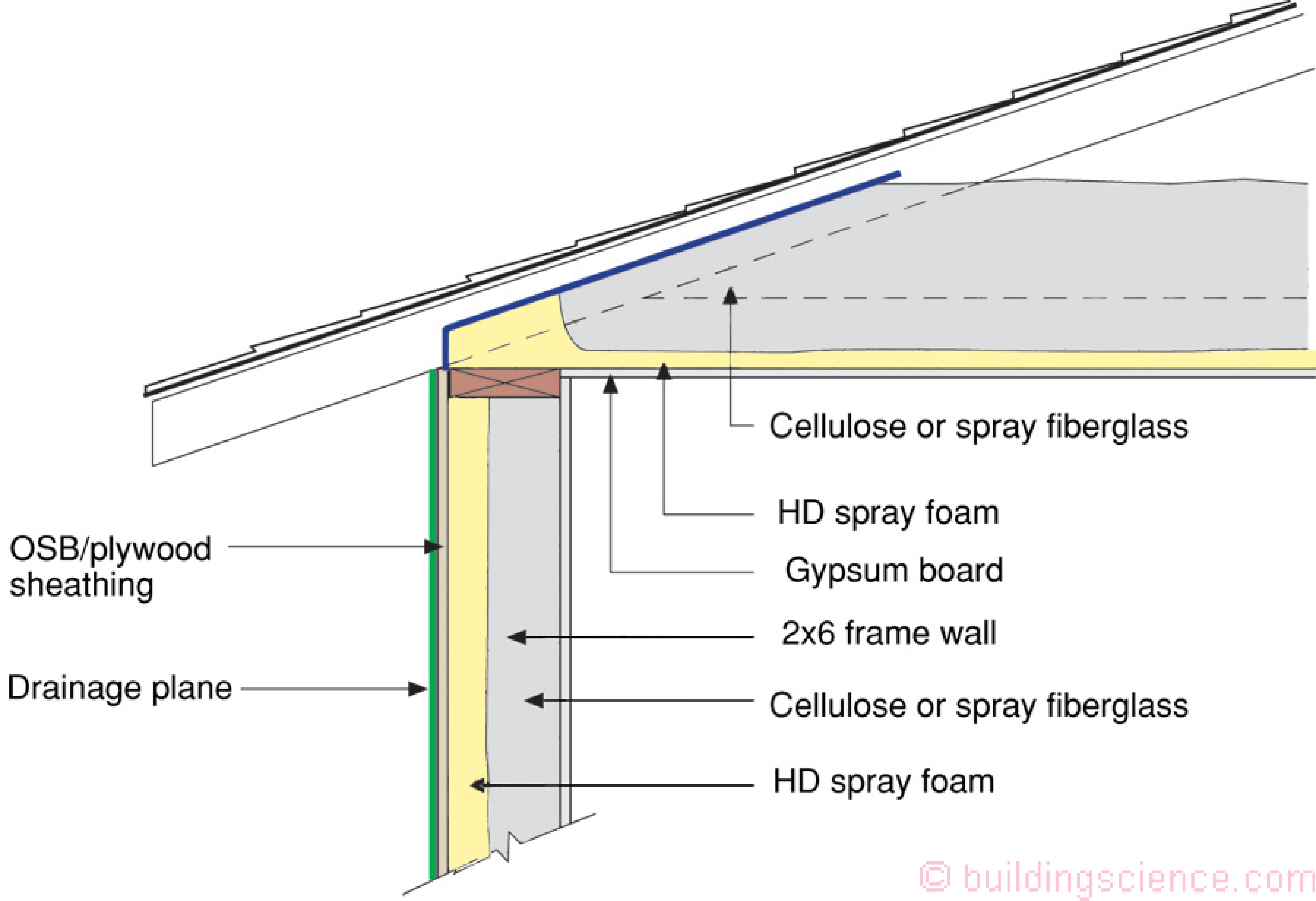

Hybrid attics can be constructed in IECC Climate Zones 5 and higher using a combination of high density closed cell spray foam and low-density open cell spray foam (Figure 6). The thickness or thermal resistance of the high density closed cell spray foam is specified by the International Residential Code (IRC) based on climate zone (Table 2). A further variation is where the low-density open cell spray foam is replaced with fiberglass or cellulose insulation (Figure 7). Again, the thickness or thermal resistance of the high density closed cell spray foam is specified by the International Residential Code (IRC) based on climate zone (Table 2).

Figure 6: Hybrid attics can be constructed using a combination of high density closed cell spray foam and low-density open cell spray foam.

Figure 7: A further variation of hybrid attics is where the low-density open cell spray foam is replaced with fiberglass or cellulose insulation.

Insulation for Condensation Control*

Table 2 *Adapted from Table R 806.5 2018 International Residential Code

Vented unconditioned attics are typically constructed using spray foam in conjunction with fiberglass or cellulose insulation. The key to the performance of vented unconditioned attics is continuity of the air control layer located at the ceiling plane. It is difficult to provide airtightness at the ceiling plane using typical sealants. Spray foam is used to seal the ceiling plane in an airtight manner (Figure 8). It is critical to provide air sealing at the perimeter to control wind washing of air permeable insulation. The spray foam creates an airtight “bathtub” that is then filled with air permeable insulation such as fiberglass or cellulose. Typically, high density closed cell spray foam is used for this application.

Figure 8: Vented unconditioned attics are typically constructed using spray foam in conjunction with fiberglass or cellulose insulation. The key to the performance of vented unconditioned attics is continuity of the air control layer located at the ceiling plane.

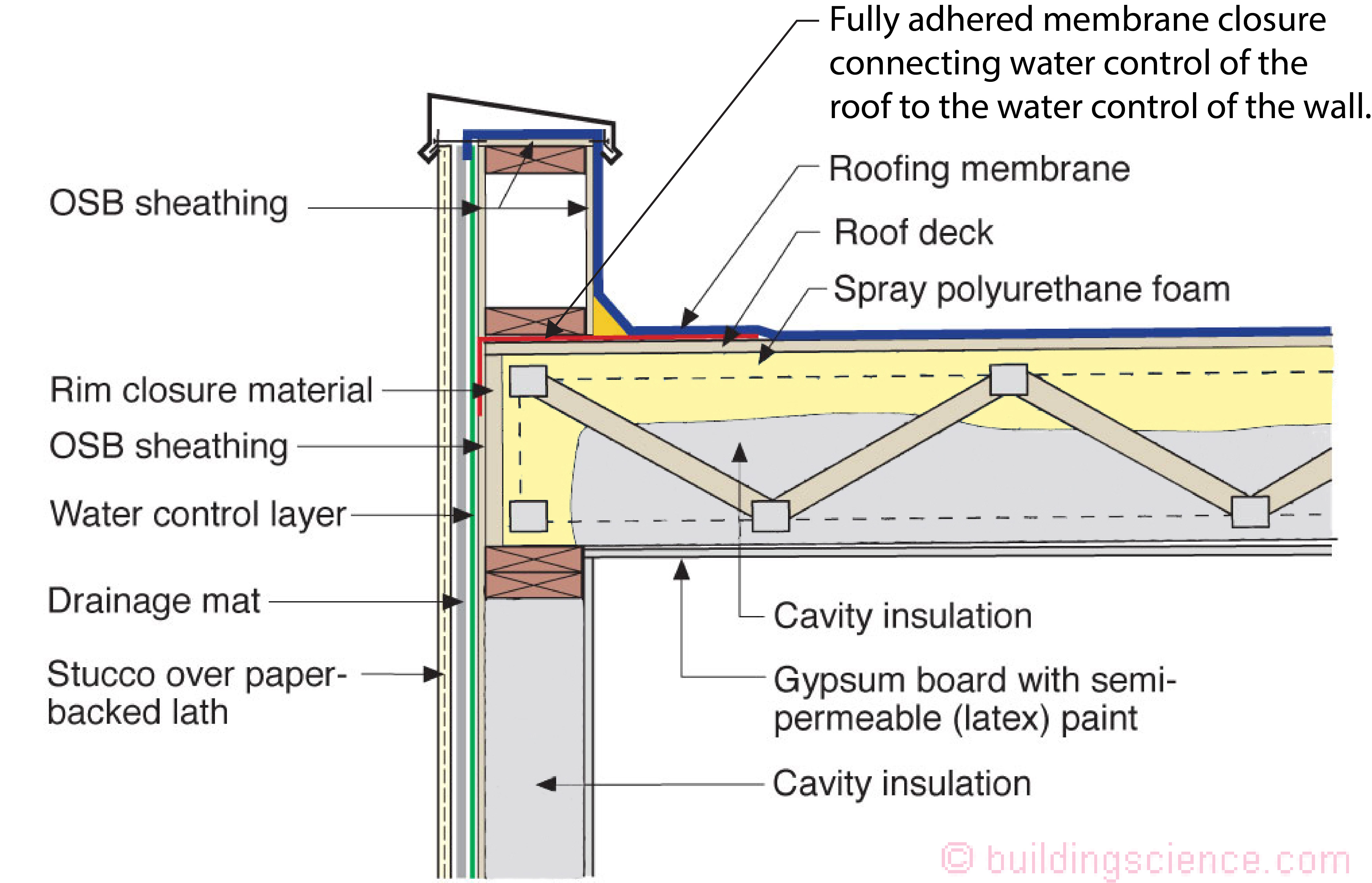

In low slope roof construction similar approaches are used to those used with unvented conditioned attics. Most low slope roof construction using spray foam use a hybrid approach where a combination of high density closed cell spray foam is used with fiberglass or cellulose insulation (Figure 9). Again, the thickness or thermal resistance of the high density closed cell spray foam is specified by the International Residential Code (IRC) based on climate zone (Table 2).

Figure 9: Most low slope roof construction using spray foam use a hybrid approach where a combination of high density closed cell spray foam is used with fiberglass or cellulose insulation.

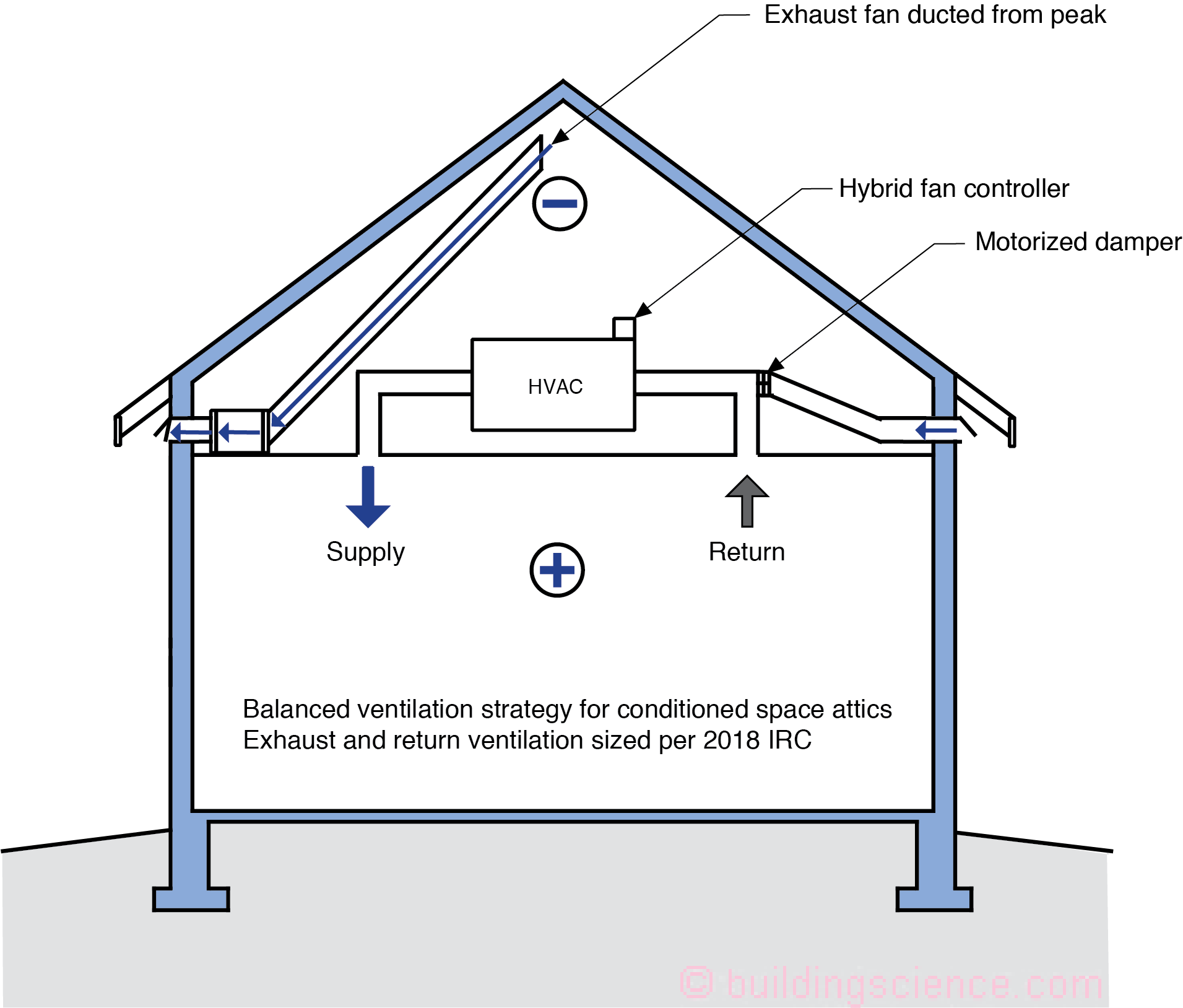

Wherever unvented conditioned attics are constructed, a means of moisture removal from the attic is necessary. The “conditioned” part of unvented conditioned attics is important. One of the best ways to remove moisture from the attic space is to provide air change[2]. In this approach air is exhausted from the peak of the attic using an exhaust fan ducted to the exterior. This creates a slight negative air pressure in the attic, and air is drawn from the house below. To create “balanced’ ventilation in the house, supply air is provided from the outside to the return side of the air handler (Figure 10). The amount of air supplied and exhausted should be the same – hence the term balanced ventilation. The quantity of this air flow should be based on the International Residential Code – 2018. To prevent over ventilation or under ventilation, a motorized damper is installed at the outdoor air supply of the system. The operation of the motorized damper is coupled or linked to the operation of the attic exhaust fan – the attic exhaust fan operates only when the motorized damper is open, and the HVAC system blower is operating.

Figure 10: The best way to remove moisture from the attic space is to provide air change. Air is exhausted from the peak of the attic using an exhaust fan ducted to the exterior.

Foundations

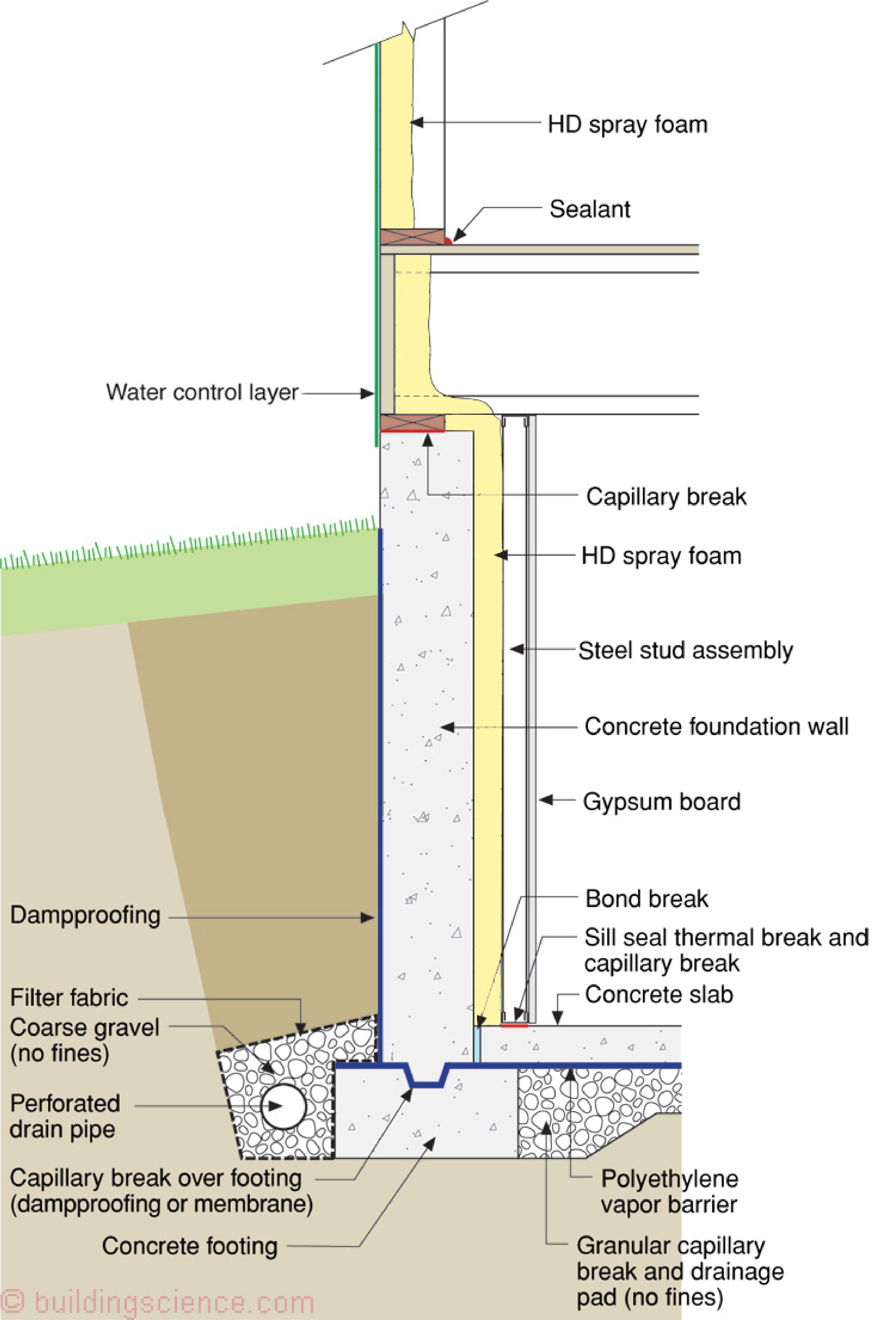

Basement foundations are best insulated on the interior thereby avoiding issues with respect to insects such as ants and termites, issues with respect to protecting exterior insulation during the construction process and protecting exterior insulation above grade during the life of the building.

Spray foam insulation can be directly applied to the interior of concrete foundation walls (Figure 11). In IECC Climate Zones 5 and higher high density closed cell spray foam is recommended. A hybrid approach can also be used in combination with fiberglass or cellulose insulation (Figure 12).

Figure 11: Spray foam insulation can be directly applied to the interior of concrete foundation walls.

Figure 12: A hybrid approach for basement foundations can also be used in combination with fiberglass or cellulose insulation.

There are two common crawlspace foundation approaches - the crawlspace is either “vented” and “not conditioned” and connected to the “outside” …or…the crawlspace is “not vented” and “conditioned” and connected to the “inside”. Of the two approaches, the most energy efficient is the not-vented conditioned approach. However, not all sites are compatible with not-vented conditioned crawlspaces such as areas with high water tables, swamps and flooding concerns.

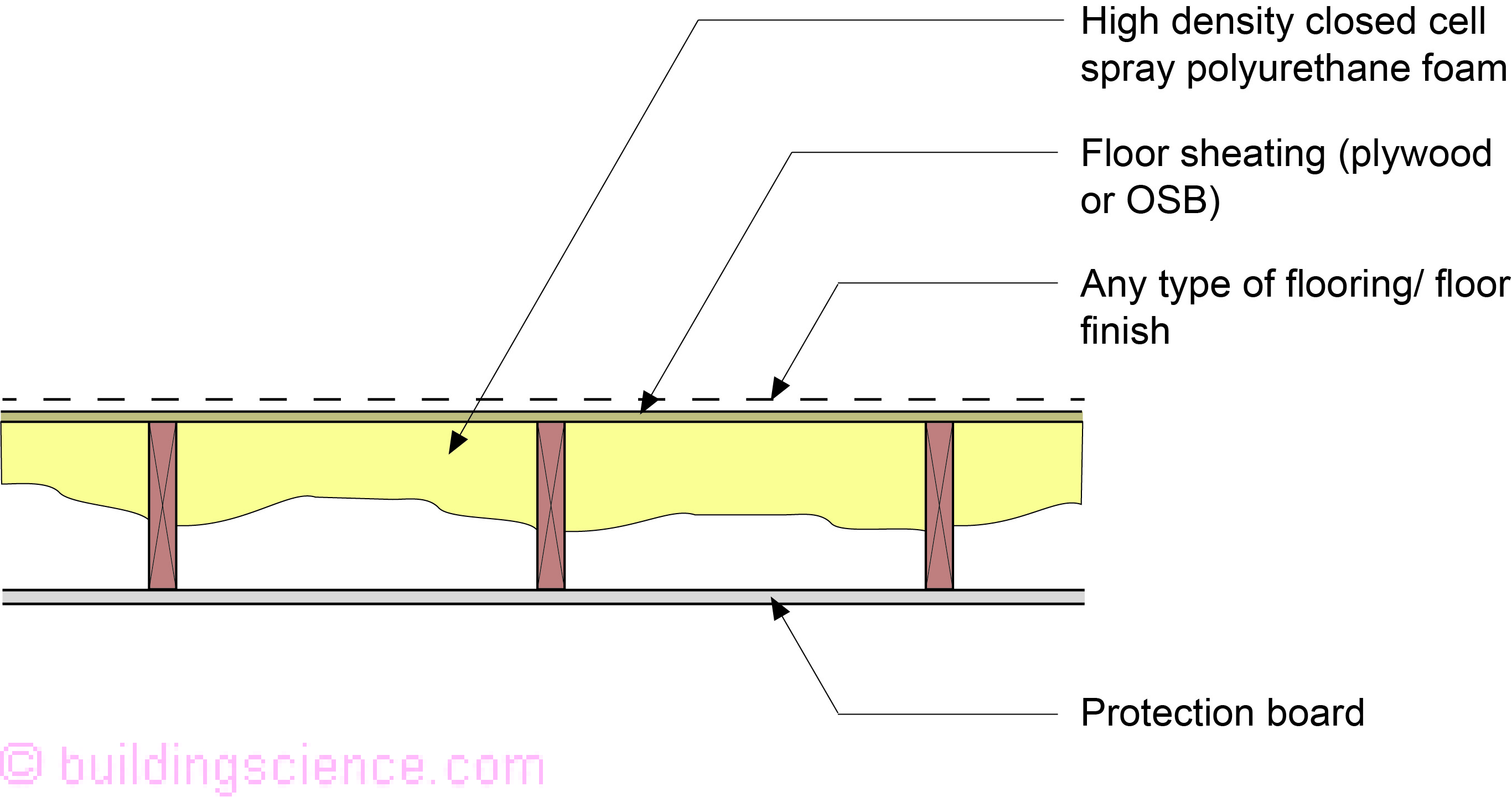

Vented crawlspaces must keep air and vapor out of the crawlspace floor framing. Only high density closed cell spray polyurethane foam should be used in all IECC Climate Zones (Figure 13 and Figure 14). A protection board such as fiber cement should be installed to prevent animals from getting into the floor assembly.

Conditioned crawlspaces should be constructed as “mini” basements and completely connected to the house (Figure 15a and Figure 15b). We looked at how to condition crawlspaces previously (BSI-115: “Crawlspaces - Either In or Out”, March 2020).

Figure 13: Vented crawlspaces must keep air and vapor out of the crawlspace floor framing. Only high density closed cell spray polyurethane foam should be used in all IECC Climate Zones.

Figure 14: A protection board such as fiber cement should be installed to prevent animals from getting into the floor assembly.

Figure 15a: Conditioned crawlspaces should be constructed as “mini” basements and completely connected to the house.

Figure 15b: Conditioned crawlspace with termite inspection gaps for high termite risk regions.

Pretty straightforward up to now…. but there are a few 800 lb gorillas hanging around. Fire is one of those gorillas. Some spray polyurethane foams burn, and some do not. Yup, there are some spray polyurethane foams around that do not burn. You read that correctly. But, most do and therefore require some form of fire protection. You have been warned. Blowing agent ozone depletion potential and greenhouse gas global warming potential characteristics are two other gorillas. Some spray polyurethane foams have very low ozone depletion potential and greenhouse gas global warming potential characteristics…. some do not. You have been informed. As for embodied carbon and carbon accounting…a couple of more gorillas...my view is that if we used the same approaches to calculate our taxes the IRS would make sure we ended up in prison…you can pretty much get any answer you want. For the time being I am focusing on energy efficiency…something I can reasonably measure. Hard to get all the gorillas to behave and dance at the circus.

[1] High density closed cell spray polyurethane foam is typically 2 lb/ft3whereas low-density open cell spray polyurethane foam is 0.5 lb/ft3. The 2 lb/ft3high density foam is also referred to as “closed-cell” spray-applied foam and the 0.5 lb/ft3 low density foam is also referred to as “open-cell”. The “cell” designation relates to vapor control. The 2 lb/ft3high density foam is around 3 perms per inch of thickness and the 0.5 lb/ft3low density foam is around 50 perms per inch of thickness. The difference is a big deal. There is more. The 2 lb/ft3high density foam has a thermal resistance – R-value – of 6.5 per inch, the 0.5 lb/ft3low density foam is around 3.5 per inch.

[2] It is not the only way, coupling the attic to the occupied space of the house is another. Dehumidification is yet another. Balanced ventilation with heat recovery or energy recovery is also an option….and as in Figure 10 when I use heat recovery or energy recovery I prefer to exhaust air from the peak of the attic and supply air to the occupied portion of the house.