This paper describes a hygrothermal modeling study, including all of the US climate zones, a range of interior humidity levels and numerous arrangements and types of insulation. The results showed that so long as airtightness is provided, and wintertime humidity is controlled, numerous unvented solutions using either or both spray foam (open and closed cell) and fibrous insulation (cellulose and mineral fiber) can be successful. Climate, the solar properties and exposure of the roofing, the air and vapor permeance of the insulation(s) and interior humidity are the most important factors to be considered in the design of moisture-safe unvented roof systems. For more information about roofs, see Popular Topics/Unvented Roof/Attic.

Wood-framed pitched roofs have traditionally constructed with fibrous insulation laid on the ceiling plane, and the large volume above this insulation well ventilated with exterior air. However, there is a growing trend toward insulating the underside of the sloped roof deck so that the volume between the ceiling plane and the sloped roof plane can be conditioned and contain HVAC systems, duct distribution, storage and even living space. In this insulation arrangement, ventilation below the deck is more difficult, expensive, and/or impractical to achieve, and so unvented solutions have attracted significant interest (i.e., unvented cathedralized attics).

The primary concern with the use of unvented roofs is the potential for moisture build up at the underside of the roof sheathing during cold weather. Rain leaks are just as dangerous. Research has shown that the good field experience with ventilated attics is due to the removal of moisture that passes through the ceiling plane by diffusion and accidental air leaks.

This paper describes a hygrothermal modeling study, including all of the US climate zones, a range of interior humidity levels and numerous arrangements and types of insulation. The results showed that so long as airtightness is provided, and wintertime humidity is controlled, numerous unvented solutions using either or both spray foam (open and closed cell) and fibrous insulation (cellulose and mineral fiber) can be successful. Climate, the solar properties and exposure of the roofing, the air and vapor permeance of the insulation (s) and interior humidity are the most important factors to be considered in the design of moisture-safe unvented roof systems.

Introduction

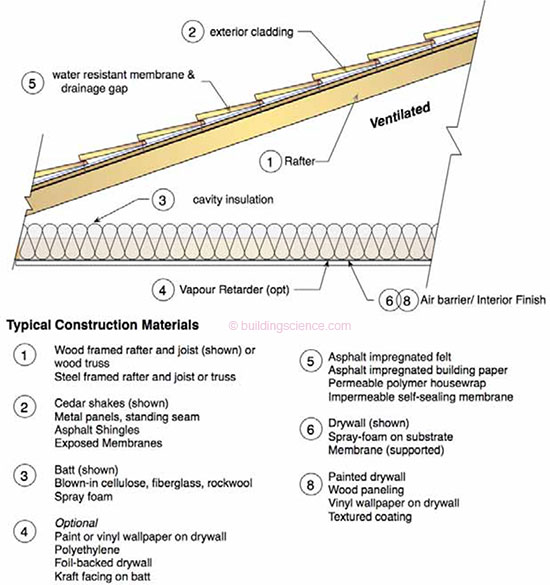

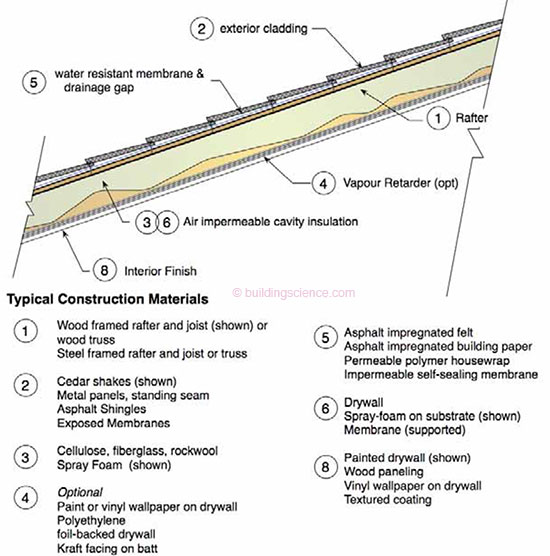

Wood-framed pitched roofs have traditionally been constructed with fibrous insulation laid on the ceiling plane, and the large volume above this insulation well ventilated with exterior air (Figure 1). However, there is a growing trend toward insulating the underside of the sloped roof so that the volume between the ceiling plane and the sloped roof plane can be conditioned and contain HVAC systems, duct distribution, storage and even living space. In this insulation arrangement (Figure 2), ventilation is difficult, expensive, and/or impractical to achieve, and so unvented solutions have attracted significant interest. This approach to insulated pitched wood-framed roofs is termed an unvented cathedralized attic.

Figure 1: Typical ventilated attic insulated at ceiling plane

Figure 2: Typicaly unvented cathedralized attic

The primary concern with the use of unvented cathedralized attics is the potential for moisture build up at the underside of the roof sheathing during cold weather. Research has shown that the good field experience with ventilated attics is due to the removal of moisture that passes through the ceiling plane by diffusion and accidental air leaks during cold weather. Despite common beliefs, field research and theoretical studies have shown that there is almost no impact on roofing temperatures by using an unvented roof approach.

A study was initiated to assist in the development of scientifically-based moisture control recommendations for installers of insulation products in unvented cathedralized attics. This paper describes this study, including its approach, results and interpretation.

Approach

A series of detailed computer simulations were conducted of the moisture performance of unvented cathedralized-attic wood roofs. Several different insulation products, ranging from highly vapor and air permeable fibrous insulation to air impermeable vapor retarding foam insulation were considered. The influence of different types of roofing materials and interior environments were considered alongside the primary variable of climate zone.

The study focused on the worst-case scenarios to define the upper limit of application for each combination of materials. Hence, the results are intended to be conservative guidance for practitioners. Nevertheless, homes may sometimes be operated at higher moisture levels than recommended in the Boundary Conditions section (see later in this paper) and this may result in moisture failures.

The WUFI Pro 4.0 hygrothermal computer model was used [Kuenzel & Kiessl 1997, Kuenzel 2006] with special enhancements [Kuenzel et al 2002] that allowed us to model back ventilation of the concrete tiles and the impact of night-sky radiation in some of the southwestern climates where this is quite important.

Roof Topology

The roofs modeled were comprised of a roofing material (either concrete tiles, wood shakes, light-colored membrane or steel, or composite shingles depending on the market) over OSB sheathing on 2x8, 2x10, or 2x12 rafters depending on climate zone. The roof was a 3-in-12 pitch roof oriented to the north for most cases. This is the worst-case scenario, as little solar radiation warms the roof during cold weather. South-facing orientations are always warmer in the northern hemisphere. Snow accumulations will add insulation values to the exterior of the sheathing and hence tend to warm the roofs, resulting in safer cold weather results. The worst-case situation would be a very thin layer of snow (little insulation) that remains on the north-facing roof: this would be similar to the case of light-colored metal roofing.

The roofing materials were chosen to cover the range of those with high solar absorption (granulated, dark colored asphalt shingles, absorptance=0.85) to those with low (smooth light colored materials such as a metal roof, light beige in color, absorptance=0.30). Because of the very different amounts of solar radiation absorbed by different roof claddings, the difference in performance can be significant, even though the chosen orientation was north-facing.

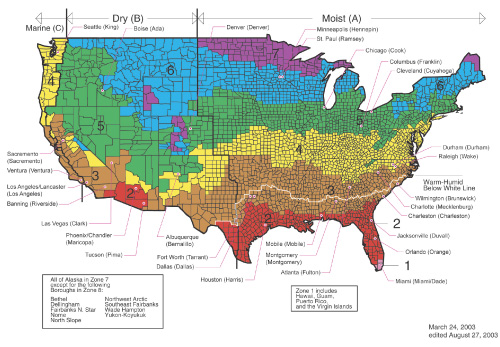

At least one set of simulations was run for each of seven climate zones in the continental United States and Alaska. These zones also cover most of the populated areas of Canada: Vancouver and area is in Zone 4C, southern Ontario (including Toronto) is in Zone 6 and most of the rest of Canada is in Zone 7. Large urban centers with available weather data were chosen for simulation.

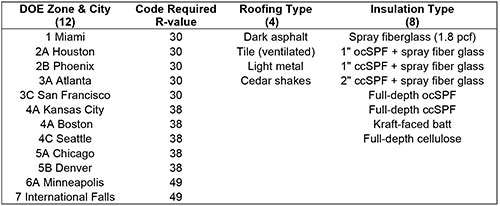

Table 1: Matrix of climate zones, roofing, R-value, and insulation types modeled

Note: ocSPF is 1/2 pound per cubic foot open cell spray polyurethane foam, ccSPF is 2 pound per cubic foot closed-cell polyurethane foam

The roof rafter space was assumed to be filled with sufficient insulation to meet the 2009 IRC code values based the DOE Zone (listed in Table 1). It was further assumed that a large enough rafter space was provided for the insulation used. In the case of Zones 6 and higher, well over 12” (300 mm) of space would be required for all insulations except the ccSPF (which can achieve R49 in a 2x10 rafter space). This places practical limits on the technologies that can be employed. The simplicity of an all closed-cell foam solution may outweigh the costs of using 14” I-joists, counter-strapping on top of 2x12 rafters, or the use of top-side rigid foam to achieve the required high Rvalues using fibrous or ocSPF.

Figure 3: DOE Climate zone map

Material Properties

Most of the material properties were chosen from the WUFI database. However, some properties were specifically developed for this project.

Spray fiberglass of 1.8 pcf density was used in several of the roof designs. The properties were provided by the manufacturer [Johns Manville 2007]. Lower density applications will not change the results of the study provided the same R-value is achieved (i.e., the vapor permeance does not change appreciably with density in such a product).

The permeance of the 1/2 pcf open-cell spray polyurethane foam (ocSPF) was taken from two manufacturers’ datasheets. This same permeance was also built into the WUFI database (R3.8/inch and 23 US perms for a 1” thickness). The permeance and R-value of closed-cell 2 pcf spray polyurethane foam (ccSPF) was based on the current range these products provide (R6.2/inch and 1.2 US perms per inch). Newer foams with a range of densities (between 0.5 and well over 2 pcf) and open cell content have different properties and these may change the results of the simulations.

The RH-dependent permeance of Kraft-facing on batts was taken from the literature [Gatland 2005]. The material properties from this research showed that although a Kraft-facing had a perm rating of less than 1 under the dry-cup test, the permeance increased significantly with increasing RH. The dry cup test procedure in the ASTM E96 standard imposes an average RH of 25%. In more humid climates, e.g. Seattle, the interior RH is much higher (e.g., around 50%) during the winter and the Kraft-facing becomes more permeable for most of the winter under these conditions.

Boundary Conditions

Boundary conditions are critical to the results of any simulation. In all cases we used hourly weather files with full solar, temperature, rain and RH data. For this work we used the 10% cold year (that is 90% of years from 1960 to 1990 have been warmer) for the exterior conditions. It is worth noting that we have previously observed that climates in North America have been warming (the most recent decade is the hottest on record), and the 10% cold year now appears to have a probability of occurrence in any given year of less than 10%. For specific situations the local heating degree days should be compared to the closest large city in Table 1.

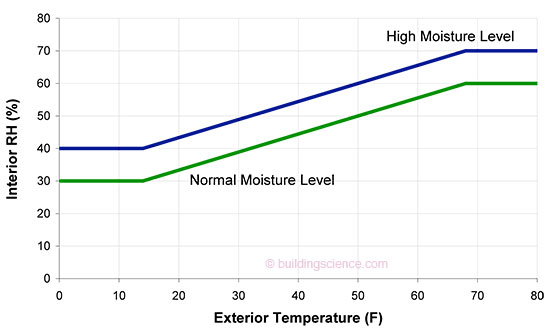

Interior RH conditions can dominate the performance of vapor open insulated systems. In fact, it is our recommendation that safe operating RH limits be provided on a tag attached to the inside of each roof that is insulated. The interior conditions were varied in the simulation from medium to high interior moisture levels. We chose the EuroNorm Standard 15026 [Euronorm 2007] to predict interior conditions. This model considers the outside temperature and adjusts the interior RH (e.g., Figure 4).

Figure 4: EuroNorm Standard 15026 model for interior RH levels

We have found that this represents how many homes behave (provided that a ventilation system according to ASHRAE 62.2 is installed and operated), although there is also a small effect of exterior air moisture content that is not temperature-dependent. For example, Chicago air in winter is noticeably drier than San Francisco (Figure 5). To assess the risk of the worst house, we also investigated the high moisture load condition shown in Figure 4. This level of moisture should be avoided in practice but could occur if the home were not properly operated (i.e., not ventilated while also airtight). High moisture level homes would experience persistent condensation on typical residential windows. . .

Download complete report here.