Some common locations for large holes in the air barrier include bathtubs, showers, fireplace enclosures, and chimneys. Holes behind tub and shower enclosures are common, as these enclosures are often installed before the interior-side air barrier of the exterior wall. Similarly, the enclosure behind a prefabricated fireplace is often left incomplete. Where the chimney flue penetrates through an insulated assembly, it is critical to maintain clearances to combustibles materials. But a non-combustible, airtight closure around this penetration is also important.

Bathtub and Shower Enclosures

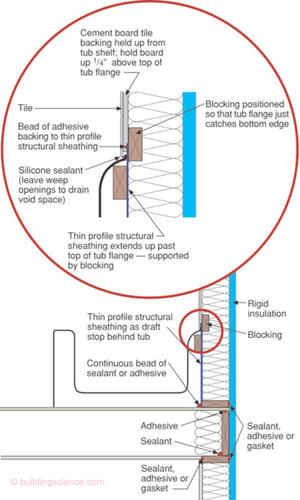

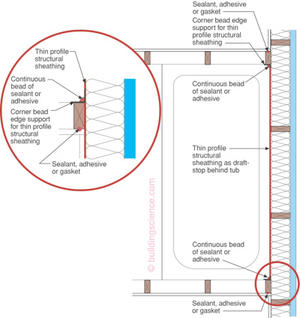

The diagrams below provide an example of draft stopping using thin profile sheathing that is installed before the tub enclosure.

Other air barrier sheathings or membranes may also be used to create an airtight draft stop behind tub and shower enclosures. If spray foam insulation is used to create an air barrier in the framing cavities, the bottom plate must still be sealed to the subfloor.

Fireplace Enclosures

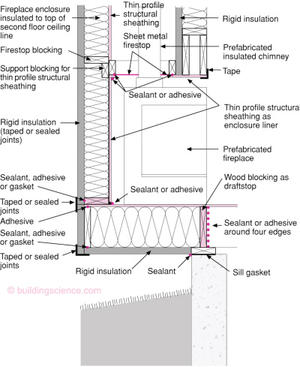

Ideally, chimneys for natural draft fireplaces are located within the interior of the building enclosure. Alternatively, chimney enclosures attached to exterior walls should be insulated full height to keep the chimney flue pipes warm to support sufficient draft.1 If air barrier continuity is not maintained in the chimney enclosure the chimney could create a serious hole in the building enclosure.

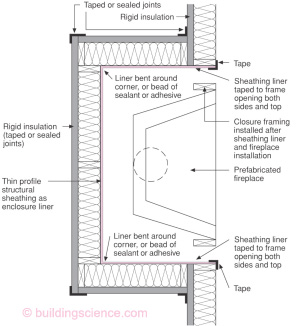

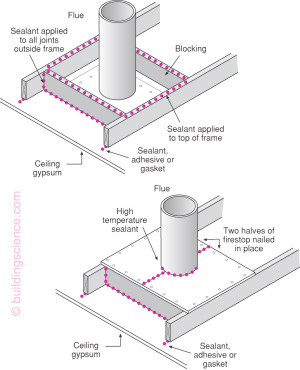

Because finishes are generally brought to the face of prefabricated fireplace units, providing an air barrier in the enclosure behind the fireplace unit can create a sequencing challenge. The diagrams below demonstrate one method of maintaining air barrier continuity by installing airtight draft stopping on the inside of the chimney enclosure and by installing an airtight flue closure.

Air Barriers—Tub, Shower and Fireplace Enclosures Details

Figure 1

Draft Stopping and Air Barrier at Tub Enclosure—Section

- Entire perimeter of draft stop material sealed to framing and subfloor with adhesive or sealant

- Seams in draft stop material sealed

- Bottom plate sealed to subfloor

- lat blocking for draft stop and tub flange support allows cavity insulation to be installed behind draft stop

- Cement board, fiber cement board or paperless gypsum board tile backing is recommended in place of moisture-resistant gypsum board (“green board”)

- Note: cement board is not waterproof; it must be coated with a fluid applied waterproofing, or a water resistive barrier applied behind it and drained

Figure 2

Draft Stopping and Air Barrier at Tub Enclosure—Plan

Figure 3

Fireplace Enclosure—Plan

- Clearances around chimney and fireplace unit to be determined by manufacturer’s recommendations and local codes

- Exterior combustion air with a damper should be provided to all fireboxes

- Draft stopping material is sealed at perimeter to framing or subfloor

- Seams in draft stopping material sealed

Figure 4

Fireplace Enclosure—Section

- Flue closure needed at top of insulated assembly

- Draft stopping material is sealed at perimeter to framing or subfloor

- Seams in draft stopping material sealed

Figure 5

Flue Closure

- Only approved high temperature sealants to be used at firestopping

- Flue closure also needed at the insulated ceiling for chimneys within the interior of the building enclosure

Use of sealed combustion, direct vent gas fireplaces eliminates the need for chimneys.