Crawlspaces should be designed and constructed as mini-basements. Crawlspaces should not be vented to the exterior (see FAQ on Crawlspace Venting). They should have their floors uninsulated, the ground vapor sealed, their walls insulated and air sealed, and their air conditioned with indoor air.

Traditional vented crawlspaces are often damp, mouldy and inhabited with pests. They have almost universally been found to be well connected to indoor air through many small unintentional air leaks in the floors, partitions, and ducts. Therefore, to ensure both durability and indoor air quality (and save energy), a crawlspace must be kept dry, conditioned to control temperature and humidity, and sealed tight to be pest free. This is particularly important for crawlspaces that contain mechanical equipment—a situation that is practically guaranteed in buildings that have a crawlspace. Mechanical systems should not be installed outside of a home in unconditioned space unless there is no practical alternative.

Crawlspaces should have a continuous sealed groundcover of vapor diffusion resistant materials, such as taped polyethylene or, preferably, a thin poured concrete slab over polyethylene with perimeter and control joints sealed. When the crawlspace ground level is below the ground level of the surrounding grade they should have perimeter drainage just like a basement. There must be good drainage away from crawlspaces (refer to Information Sheet 101: “Groundwater Control”). Crawlspace design and construction should also provide drainage for potential plumbing leaks or flooding incidents by sloping the ground level to a drain.

Crawlspaces should be insulated on their perimeters — they should not be insulated between floors. Crawlspaces insulated on the perimeter are warmer and drier than crawlspaces insulated between the crawlspace and the house.

Crawlspace walls should be insulated with non-water sensitive insulation that prevents interior air from contacting cold basement surfaces—the concrete structural elements and the rim joist framing. Allowing interior air (that is usually full of moisture, especially in the humid summer months) to touch cold surfaces will cause condensation and wetting, rather than the desired drying. The structural elements of below grade walls are cold (concrete is in direct contact with the ground)—especially when insulated on the interior. Of particular concern are rim joist areas—which are cold not only during the summer but also during the winter. This is why it is important that interior insulation assemblies be constructed as airtight as possible.

The best insulations to use are foam based and should allow the foundation wall assembly to dry inwards. The foam insulation layer should generally be vapor semi impermeable (greater than 0.1 perm), vapor semi permeable (greater than 1.0 perm) or vapor permeable (greater than 10 perm) (Lstiburek, 2004). The greater the permeance the greater the inward drying and therefore the lower the risk of excessive moisture accumulation.

Up to two inches of unfaced extruded polystyrene (R-10), four inches of unfaced expanded polystyrene (R-15), three inches of closed cell medium density spray polyurethane foam (R-18) and ten inches of open cell low density spray foam (R-35) meet these permeability requirements.

In crawlspaces where the insulation material will need to be covered by a fire/ignition barrier, it may be acceptable to use fire-rated foil-faced insulations. However, such requires careful attention to supplemental moisture management strategies. With vapor impermeable facings on interior insulation, it is possible that water may accumulate between the insulation facing and the inside surface of the foundation wall. The airtightness of the assembly is, therefore, extremely important to prevent the exchange of air between this damp interface and anywhere else in the building.

Consult the resources listed below for specific guidance.

In cold climates or in very low-energy buildings, installing insulation below the ground cover is recommended. When a slab is poured over the ground in this application the temperature and humidity conditions in the crawlspace become very stable and essentially identical to the interior.

To remove any small incidental sources of moisture, it is important that some air circulate from the living space into the crawlspace. It is for this reason the approach is called a “conditioned crawlspace” not a “unvented crawlspace.” Flows of 50 cfm per 1000 sf when the mechanical system operates are recommended.

In all cases, a capillary break should be installed on the top of the footing between the footing and the perimeter foundation wall to control “rising damp.” It is also necessary to install a capillary break between the foundation wall and framing.

If it is not possible to treat the crawlspace as a part of the house such as in flood zones in costal areas or in dry climates where it is not necessary, it is important to construct the house such that the crawlspace is isolated from the house—outside of the building boundary. These situations should follow recommendations for homes built on piers.

Crawlspace Insulation Details

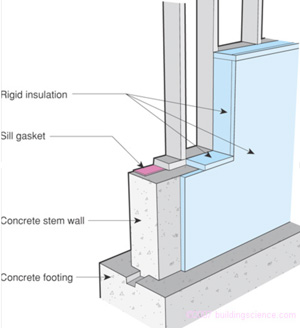

Figure 1

Rigid Insulation Wraps Concrete Surfaces

- Cold concrete foundation wall must be protected from interior moisture-laden air in summer and winter

- Rim joist assembly must be insulated with air impermeable insulation or insulated on the exterior

- Rigid insulation completely wraps exposed concrete preventing interior air from contacting potential concrete condensing surface

- Seams in rigid insulation and joints to other materials sealed to provide air barrier

- Rigid insulation is vapor semi-impermeable or vapor semi-permeable (foil facing or plastic facing not present)

- Rigid insulation provides bond break between foundation wall and slab when insulation is installed before slab is poured

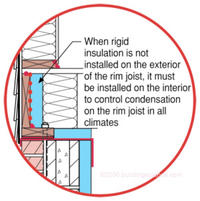

Figure 2

Interior Rim Joist

- Air barrier needed to protect the rim joist from interior moisture-laden air in summer and winter

- Seams in rigid insulation and joints to other materials sealed to provide air barrier

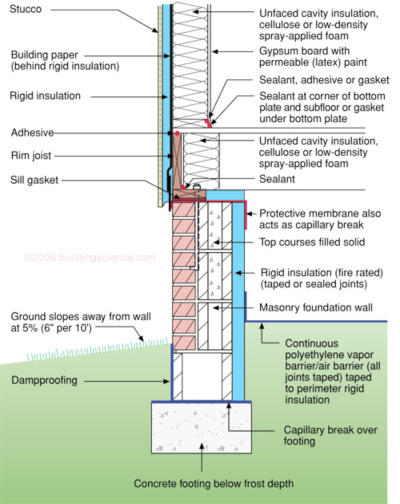

Figure 3

Rigid Insulation with Supplemental Insulated Frame Wall Assembly

- Rigid foam insulation board assembly must provide continuous air barrier and capillary break around concrete foundation

- Rigid insulation is vapor semi-impermeable or vapor semi-permeable (foil facing or plastic facing not present)

- Protective membrane adhered to top of foundation wall and wrapped over top of insulation

- Insulation material non-moisture sensitive and not subject to degradation with ground contact