Spain gave Florida to the United States in exchange for the United States giving up any claims on Texas. We all know how that turned out. Nobody really wanted to live there except the Seminoles until air-conditioning was invented. It took a New York boy by the name of Willis Carrier to make the state habitable for the rest of us.1

The good news was that air-conditioning came to Florida. The bad news was that air-conditioning came to Florida. With air-conditioning came people. Also with air-conditioning came mold.2

When you air-condition you make things cold. When things get cold they sweat if it is humid. What are the odds that it gets humid in Florida? So let’s build air-conditioned boxes in Florida lined with paper. What could possibly go wrong? Oh I forgot to mention the part about rain. It also rains in Florida. Oops, one more thing, Florida is pretty much a swamp. This air-conditioned paper lined box also gets rained on while it is sitting on wet ground. We’re not done yet. Occasionally there are hurricanes and wildfires.

This Florida box gets wet from underneath, from the sides and top and sometimes blows away. Thank god that most of them are so wet they can’t burn, they just smolder.

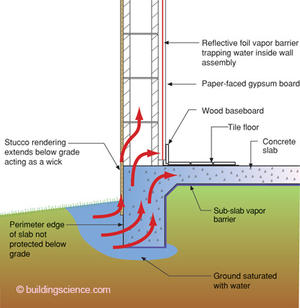

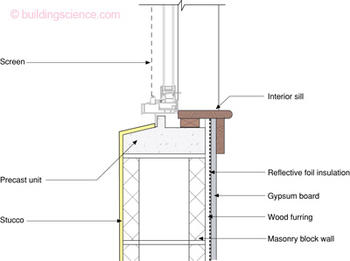

It’s not like we don’t understand the physics of building on wet ground. You build on top of it and you prevent water from wicking into the building by capillarity. But in Florida we seem to go out of our way to do it wrong. We use capillary active materials like concrete and block and stucco and configure them in such a manner as to maximize damage (Figure 1a). We don’t wrap a sub-slab vapor barrier capillary break around the perimeter of the foundation and we extend a stucco cladding into the ground in order to suck every last available drop of water in the ground into the structure. But we’re not done yet, we line the interior with a reflective insulation foil-faced vapor barrier reinforced with mold food (a.k.a. “kraft paper”).3 There’s more. We rain on the sides of the structure (Figure 1b). We apply the stucco directly to concrete block and assume that the stucco (oh, I forgot, also the paint on the stucco) keeps the rain out. We call this “faith-based rain control.” The stucco leaks, the paint leaks, the block leaks, and the wall can’t dry to the interior because of the reflective insulation foil-faced vapor barrier.

Figure 1a: Maximizing Damage—Wicking water inward at perimeter while trapping water in the assembly with an interior reflective insulation foil faced vapor barrier.

Figure 1b: Rain Penetration—There are only two kinds of stucco – stucco that leaks and stucco that will leak… Notice that the reflective insulation foil faced vapor barrier traps water in the wall.

Photograph 1: Unique Florida Experience—Baseboard gets moldy, gypsum board at baseboard gets moldy, kraft paper facing of reflective foil gets moldy…

Couple the capillary active materials, wet ground, rain, the mold sensitive materials, air-conditioning and wrong-side-of-the-assembly vapor barriers and we get a unique Florida experience (Photograph 1).

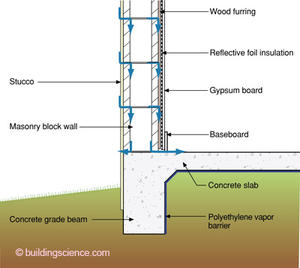

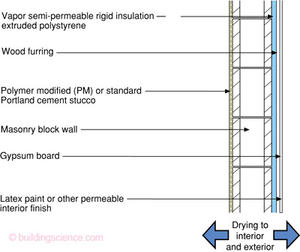

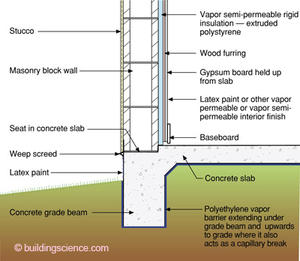

It does not take much to make these problems go away. Construct a flow-through assembly from non-water sensitive materials, and also use the same non-water sensitive materials to protect the water sensitive materials inboard of them (Figure 2a). Install a plastic vapor barrier and capillary break completely under the perimeter foundation grade beam (Photograph 2). Use a vapor semi-permeable rigid foam insulation that water does not hurt to replace the foil reflective insulation vapor barrier (Photograph 3). This same rigid foam insulation protects the interior water-sensitive paper faced gypsum lining. Then don’t extend the stucco into the ground and construct the slab with a perimeter “seat” that acts as a concrete flashing that drains rainwater penetrating the painted stucco rendering out of the block wall at its base and protect the exposed concrete slab edge with a hygrophobic vapor permeable coating – a.k.a. “latex paint” (Figure 2b).

Figure 2a: Vapor Flow-Through Assembly—Wall dries in both directions. Interior vapor semi-permeable rigid insulation is not moisture sensitive and also protects the water sensitive interior paper faced gypsum lining.

Photograph 2: Perimeter Capillary Break—Plastic sheet extends out under perimeter of slab edge foundation. Plastic skirt is attached to perimeter form boards protecting below grade portion of exterior slab edge.

Photograph 3: Vapor Semi-Permeable Rigid Insulation—Note the steel stud interior wall framing is supported by brackets that do not penetrate the foam insulation but are installed over the top of the foam insulation.

Figure 2b: Exterior Wall Done Right—Seat in the slab, vapor semi-permeable non-water sensitive interior rigid insulation, stucco not extending into the ground, latex paint on the exposed slab – it does not get much better than this.

Not extending the stucco into the ground also improves termite resistance. The little buggers can pass through tiny gaps or flaws that arise from incomplete adhesion of the stucco to the concrete slab edge of the foundation perimeter.

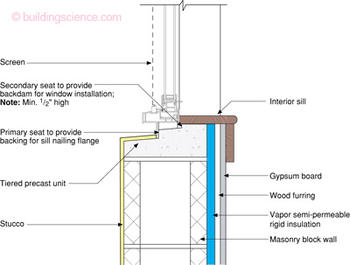

Because we clearly want to maximize the water entry into Florida buildings we do things to window openings that even surprise me – the fact that me, a noble-faired, long haired leaping gnome – should be surprised, mmmm….but there I was4…. For good structural engineering reasons, but for bad water management reasons the bottom of masonry window openings in Florida are typically lined with precast elements that are manufactured with a vertical ridge (Figure 3a) that serves to inadvertently direct rainwater that leaks through a window unit or that penetrates the window-to-wall interface inward (Photograph 4). And the reflective foil-faced vapor barrier once again does not help matters by trapping the water in the wall. Makes you want cry.

Figure 3a: Rainwater Injection System—Ridge on precast designed to structurally resist wind pressures during hurricane events. Unfortunately this ridge results in water draining inward into the building rather than outward. Notice that the reflective insulation foil faced vapor barrier traps water in the wall.

Photograph 4: Leakage Path—Yes, they all really do leak; at the window-to-wall interface and through the window itself.

Again it does not take much to make this type of problem go away. Just “tier” the precast unit at the bottom of the window opening by adding a secondary seat thereby draining penetrating rainwater back to the exterior (Figure 3b).

Figure 3b: Drain the Rain—Tiered precast element draining water to exterior while providing structural load resistance.

With the exterior walls wet through such previously described clever practices can we apply any other innovative technology that can suck moisture deep into the structure and draw any associated mold into the breathing zone? Easy, as we who reside in the Republic are a clever bunch. Why not configure the air-conditioning systems in such a manner as to develop interior negative pressures while simultaneously locating the systems in the most severe environmental conditions possible to minimize their life while maximizing energy consumption?

First, vent the attic space so that during rain events when it is particularly windy5 rain can enter through roof vents – a particular form of rainwater harvesting common to Florida. Note to folks who don’t know much about hurricanes, you can’t keep rain out of vented attics during hurricanes, but you can keep rain out of attics that are not vented during hurricanes.

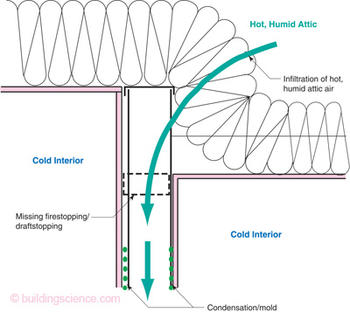

Second penetrate the ceiling with lots of service penetrations, framing drops, trey ceilings and every conceivable change in height.

Third, locate the air-conditioning air distribution system in the vented attic. What is the hottest and most environmentally inhospitable location in a building where surface temperatures can exceed 150 degrees F.? Yes, you guessed it, a vented attic. The extreme temperatures just ruin equipment and ductwork.6

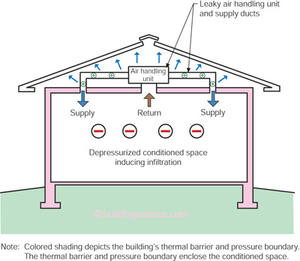

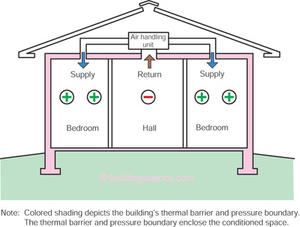

Finally, and most importantly, make this air distribution system leaky (Figure 4a). The resulting negative pressure in the conditioned space draws humid air from the attic into the belly of the beast (Figure 4b). We can enhance this negative pressure by not providing return paths to the air handlers and closing doors (Figure 4c).

Figure 4a: Going Negative—Leaky duct distribution system in a vented attic is a recipe for problems.

Figure 4b: Leakage Path—Unfortunately a common experience.

Figure 4c: Door Closure—Closing doors magnifies the effect of pressures. All we need is a dependable return path and this particular problem goes away.

These negative pressure fields draw attic air not just into interior framing but also down exterior walls humidifying surfaces along the flow path while simultaneously picking up available contaminants along the way. These negative pressure fields also draw air from under the slab into the occupied space through slab penetrations (I particularly like the bathtub plumbing trap opening) and from the garage (the “Kevorkian Option”).

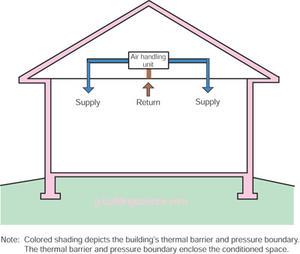

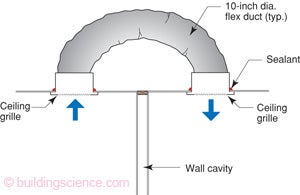

Wow, how to fix this mess? Once again pretty simple approaches work well. Construct the attic as a conditioned space thereby locating the air distribution system within the conditioned space and reducing the major adverse effects of system leakage (Figure 4d). The technology of choice is spray foam applied directly to the underside of the roof deck (Photograph 5). This approach also handles the rain penetration through attic vent problem. It also addresses the durability problem of the ductwork. It is also energy efficient. There are clearly a lot of things not to like about this approach. The next step is to install “jump ducts” (Figure 4e) to provide adequate return paths when doors are closed without sacrificing noise transmission performance.

Figure 4d: Moving the Boundary—Locate the ducts inside by moving the air barrier and thermal barrier to the underside of the roof deck. Ducts are now inside. Duct leakage does not lead to major problems. Save some energy, be nice to the planet.

Figure 4e: Jump Ducts—Provide dependable return path without noise transfer.

Photograph 5: Unvented Roof—Spray foam insulation applied to the underside of the roof deck bringing the attic and the ductwork inside the conditioned space.

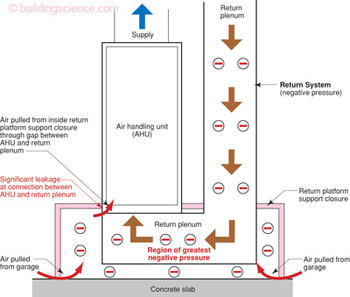

What other innovative technology is available to hurt us in Florida? My absolute favorite because it is so subtle and nefarious is the return platform in the garage (Photograph 6). The return platform encloses the return duct. The return duct within the return platform leaks leading to a negative pressure within the return platform (Photograph 7 and Figure 5). You get to suck air out of the garage and you get to suck air from under the slab - the return platform creates an elegant capture chamber for radon, soil gas, herbicides, termiticides and other good stuff.

It is not impossible to build in Florida. It is not even difficult to build in Florida. It is just different. The rain, humidity, swampland, and Canadian émigré’s make it an interesting place, not a bad place. I didn’t want to cast aspersions after all I’m just a soul whose intentions are good: Oh Lord, please don’t let me be misunderstood.7

Photograph 6: Garage Return Platform—After a vented attic what is the worst possible place to locate an air-handler? Yes, you guessed it, the garage. Florida HVAC at its best.

Photograph 7: Pressure Measurement—Return platform goes negative due to return leakage.

Figure 5: Nefarious Return Platform—The fix for this is to make the return side tight and “bleed” the pressure in the return platform enclosure by installing a “grille” through the enclosure connecting the platform enclosure to the space it is in.

Footnotes

Yes, I know that John Gorrie, a legendary Floridian, invented an ice-making machine to cool his hospital patients in Apalachicola, Florida in the 1840’s but the idea of what we consider modern air conditioning was never fully developed until Willis Carrier came along.

Everybody take a Valium. Yes, there was lots of mold in Florida buildings before the advent of air-conditioning, but hyperbole is allowed in a column written by me. Think of air-conditioning as the fertilizer that helped improve mold yield per acre of floor area.

This radiant barrier insulation nonsense is getting out of hand. If you think that it provides any thermal benefit on the inside of the typical mass wall I have some swamp-land in Florida that is for sale…

I just love Eric Burdon, founding member and vocalist of the Animals. This non-verbatim quote comes from Spill the Wine and his subsequent band Eric Burdon & War.

My favorite Nobel Prize winner at it again: Svante Arrhenius.