In cold climates, the primary purpose of attic ventilation is to maintain a cold roof temperature to avoid ice dams created by melting snow, and to vent moisture that moves from the conditioned space to the attic. In cooling dominated climates, the primary purpose of attic ventilation is to vent hot air, heated by solar gain on the roof, thus reducing the cooling load contribution from the roof. The magnitude of the roof cooling load contribution is often in the area of ten percent of the total cooling load for an occupied house.

Introduction

Traditionally, building codes have required that attics of residential buildings be vented. The ventilation requirement varies between one square foot of net free ventilation area per 300 square feet of attic floor area (1:300) to one square foot per 150 square feet (1:150). In cold climates, the primary purpose of attic ventilation is to maintain a cold roof temperature to avoid ice dams created by melting snow, and to vent moisture that moves from the conditioned space to the attic. In cooling dominated climates, the primary purpose of attic ventilation is to vent hot air, heated by solar gain on the roof, thus reducing the cooling load contribution from the roof. The magnitude of the roof cooling load contribution is often in the area of ten percent of the total cooling load for an occupied house. The need for attic ventilation in hot and hot-humid climates has recently come into question. It has been suggested that by moving the ceiling air barrier and thermal barrier to the plane of the roof, that better building airtightness can be more easily achieved, and that the elimination of heat gain to the attic air distribution ducts would more than offset the additional heat gain caused by not venting the attic. To investigate this further, both a computer modeling study and an experimental study in Las Vegas, Nevada were carried out.

Computer Modeling Study

A computer modeling study was performed to determine the effects of sealed residential attics, in hot climates, on space conditioning energy use and roof temperatures (Rudd, Lstiburek 1996). Results showed that, when compared to typically vented attics with the air distribution ducts present, the sealed “cathedralized” attic (i.e. sealed attic with the air barrier and thermal barrier [insulation] at the sloped roof plane) can be a good way to minimize or eliminate attic moisture accumulation potential in hot-humid climates, without an energy penalty. In addition, use of the sealed “cathedralized” attic in hot climates can be a successful approach to avoiding pervasive problems associated with ducts located in attics and air leakage at the ceiling level, without energy penalty.

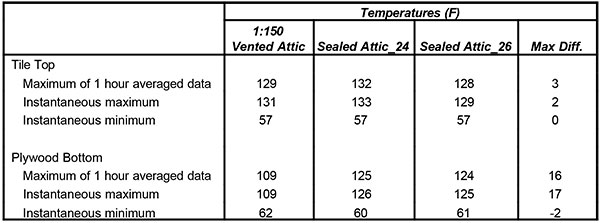

Peak summer day simulations for Las Vegas showed that the temperature of black roof shingles did not vary by more than 8°F, whether the attics were sealed or vented. The maximum predicted black roof shingle temperature for the sealed “cathedralized” attic was 204°F. For white tile roofs, the tile top temperature was, at maximum, 3°F hotter for the sealed attic compared to the vented attic. The maximum predicted white roof tile temperature for the sealed “cathedralized” attic was 132°F.

Annual simulation results for Las Vegas showed that the sealed “cathedralized” attic, compared to the vented attic with the air distribution ducts in the attic, could save 4% on space conditioning energy, with no duct leakage assumed. When typical duct leakage was modeled (10% return leak, 5% supply leak), the sealed “cathedralized” attic could save 10% on space conditioning energy.

Experimental Setup

In a Las Vegas subdivision, constructed by Pulte Homes, three houses, all of the same floor plan, elevations, and cardinal orientation, where chosen for the experimental study. Two of the houses were constructed with a sealed attic and with the ceiling insulation installed tightly under the plywood roof deck. The reference house had a conventional vented attic, designed for 1 square foot of net free vent area per 150 square feet of attic floor area, with the ceiling insulation installed normally above the ceiling gypsum board. Temperature sensors (special limits of error Type T thermocouples) were installed according to Table 1. The output from these temperature sensors, and the solar radiation sensor, were recorded by a datalogger with one microvolt resolution. Energy use measurement of the outside condensor-compressor unit of the vapor compression cooling system was accomplished by a compact current transducer and voltage datalogger located inside the units wiring compartment.

Table 1: Temperature measurements and solar radiation measurement for vented and sealed attic study

| 1:150 Vented Attic | Sealed Attic #24 | Sealed Attic #26 |

| Tile top Plywood bottom Attic air Insulation top Ceiling bottom Inside air | Tile top | Tile top Plywood bottom Insulation bottom Attic air Ceiling top Ceiling bottom Inside air Solar radiation |

Results of Experimental Study

Two days of monitored data, September 22 and October 5, 1996, were selected for analysis. Other days were available, but were invalidated due to interruptions by construction trades or unusually cool weather. Both days were similar, in that they were weekend days, the outside temperature peaked at 92°F, and solar radiation peaked between 700 and 800 W/m2.

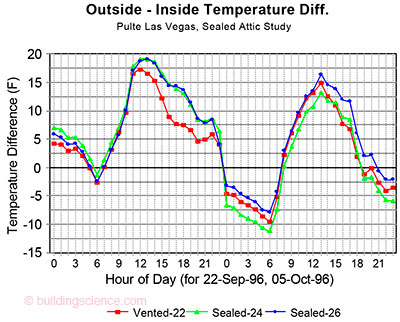

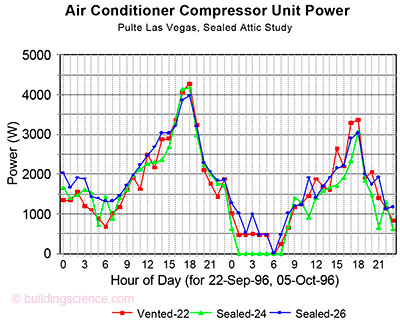

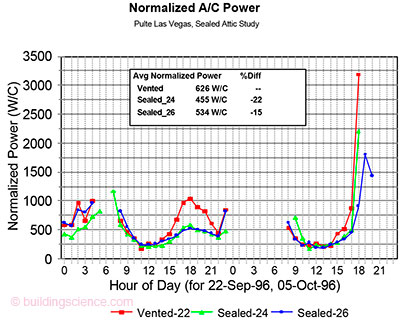

It was not possible to keep exactly the same thermostat setpoint between the houses during the test period. Figure 1 shows the outside to inside temperature difference for each house. In order to properly determine the percentage difference in cooling energy use between the houses, the cooling power, Figure 2, was normalized for the actual outside-to-inside positive temperature difference. The normalized results, shown in Figure 3, indicate that the two sealed attic houses used an average of 19 percent (between 15 and 22 percent) less cooling energy than the reference 1:150 vented attic house. The sealed attic houses, being part of an advanced building program sponsored by the U.S. Dept. Of Energy, also had higher performance windows with a low-e coating. This building envelope improvement may have been responsible for as much as 3% of the cooling energy use difference, leaving the substantial portion of the savings being due to the sealed attic with the air distribution ducts inside the air and thermal barrier.

Figure 1: Outside to inside temperature difference for the vented (1:150) and sealed attic houses

Figure 2: Power draw of outside compressor-condenser unit of cooling systems for vented (1:150) and sealed attic houses

Figure 3: Temperature normalized cooling power draw for vented (1:150) and sealed attic houses (where outside to inside temperature difference was greater than or equal to 1 C).

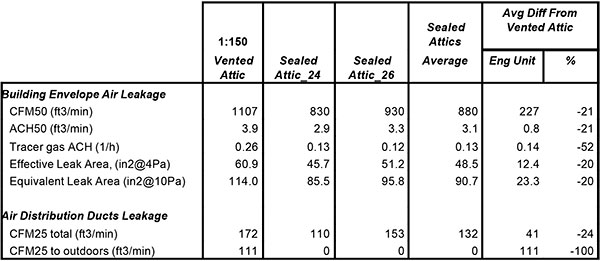

Table 2 lists the air leakage test results for each of the houses. As shown, the sealed attic houses had lower air leakage. The duct systems for the sealed attic houses had an average of 41% less total air leakage, and, most importantly, no measurable air leakage to the outdoors.

Table 2: Air leakage test results

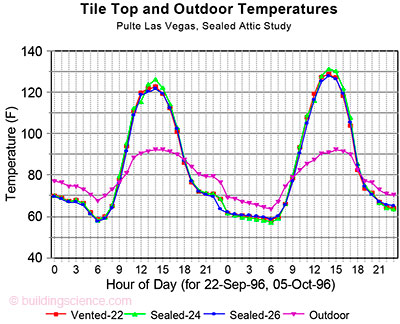

Temperature measurements showed that the top of the red roof tile did not vary by more than 3°F between the 1:150 vented and sealed attics. This agreed well with the 3°F modeled prediction for white tile roofs on the peak cooling day (110°F outdoor air). The measured temperature at the bottom of the plywood roof sheathing was, at maximum, 17°F hotter for the sealed attic roofs. Table 3 summarizes these roof temperature results. Figures 4 and 5 show the times series data for the comparison of tile top temperature and plywood bottom temperature for the sealed and vented attics.

Table 3: Summary of tile top and plywood bottom temperature extremes

Figure 4: Tile top and outdoor temperatures for the vented (1:150) and sealed attic houses. . .

Download complete report here.