Buildings don’t work the way they used to.1 Folks are always saying stuff like this. But let me make the case regarding just one factor and you decide. There are other factors of course, but I want to focus on only one for the moment. This one over-arching factor is the amount of energy exchange across the building enclosure.

I think that higher levels of thermal resistance and reduced heat gain across building enclosures has forever changed the performance of buildings—and not necessarily in a good way. And things are going to get worse before they get better. Sound familiar?

The lens I am going to use to look at this factor is moisture. Why? It is one of the principal damage functions acting on materials along with heat and ultra-violet radiation.2 I think moisture is the key to understanding the performance of buildings in general—and in this particular case—in specific.

The consequence of this reduced energy exchange is beginning to be seen all over the place: mold, part load humidity problems, rot, and corrosion. Highly insulated building enclosures with reduced heat gain have low drying potentials and increased interior moisture loads. When they get wet they don’t dry. Stuff is beginning to stink, rot, break and annoy.

There are two things to look at here. Levels of insulation and airtight assemblies and heat gain through glazing as well as roof assemblies and interior loads. Adding insulation and providing airtight assemblies reduces energy flow. That is a good thing right? Well, no—not always. Less energy flow from the inside to the outside, the colder things on the outside of the building get in the winter. The colder these things get, the wetter these things get and the wetter they stay. This is not good. The less energy flow from the outside to the inside in the summer and the less heat that is generated inside in the summer means the less the air-conditioning system runs. This is a good thing right? Well, no—not always. We create something called “the part load humidity problem.”

Higher Levels of Thermal Resistance

How do we dry wet wood? We kiln dry it. We heat the wood so that the water in the wood is warmer than its surroundings. We add energy to the water and it evaporates. There is a huge exchange of energy. When we put warm wet coffee beans in a room with very cold surfaces we call it freeze-drying. The moisture leaves the coffee beans and accumulates on the cold surfaces. There is a huge exchange of energy. The greater the rate of energy exchange the greater the rate of moisture movement. Drying cannot happen without an exchange of energy.

When my Mom and Dad bought their first house in Toronto, Canada in 1957 there was no insulation in the walls and the house was leaky to air—it had a high air change driven by a traditional chimney. We lived in a 1,200 square foot house and in January, when the outside temperature dropped to 0 degrees F., Momma cranked up the 300,000 Btu oil furnace to maintain an interior temperature of 70 degrees F. The energy flow across the building enclosure was enormous, but oil was cheap, and we were comfortable and happy. The energy flow was so enormous the building enclosure was simultaneously kiln dried and freeze-dried. In fact, the drying potential was so high, we were uncomfortably dry. As a result Poppa insisted that the furnace have a new fangled gadget attached to it—called a humidifier. How things have changed.

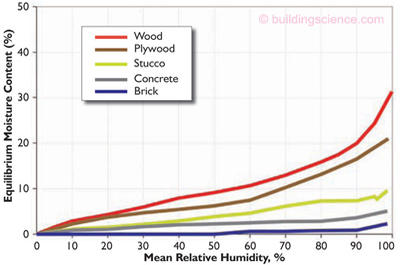

Well what changed? We’ve begun to insulate—and insulate exceptionally well—and we’re getting the assemblies “tighter” to air change and convection. That results in two things—less energy exchange therefore less drying potential—and things on the exterior side of the enclosure are colder in the winter. Things being colder on the outside lead to something most folks don’t consider. Many building materials are hygroscopic (Figure 1). This means they absorb moisture based on relative humidity. Even more strangely, they don’t care about vapor pressure except if it affects relative humidity. This is a big deal. In fact it is a huge deal.

Figure 1: Sorption Curve for Common Building Materials—Note that moisture content goes up as relative humidity goes up. There is no temperature dependence or vapor pressure dependence except where temperature affects relative humidity or where vapor pressure affects relative humidity.

Quick, snap quiz, psychrometric chart stuff….as the temperature drops, and vapor pressure is kept constant, what happens to the relative humidity? Buzz/Clang/Bell. Yes, folks, you are correct, the relative humidity goes up. The implications are staggering. Just making things on the outside of your building cold, hygroscopic things, makes them wetter. Period, end of story. But, but, the moisture content of the outside air in the wintertime is low. Yes, grasshopper, it is, but its’ relative humidity is high. The amount of moisture in the absolute sense is low, but in the relative sense it is high. And hygroscopic materials don’t care about the absolute sense; they only care about the relative sense. Why? Second Law stuff—isn’t it always?

Check out Photograph 1. Nice, normal, everyday type of house in Cleveland, OH. Twenty years old, no insulation in the wall cavities, built in 1965 (yes, the photograph was taken in 1985—we did have camera’s back then...). The house was perfectly happy at this point for twenty years. Then the homeowner decides to do something crazy, he decides to insulate the exterior walls to save energy and has the cavities blown with dry cellulose. What a dumb idea in 1985 eh? But, never the less, it was a beautiful job, no voids, yes it can be done, and yes it was done. No voids, no convection (Photograph 2—notice how young this engineer once was). Next thing you know, the paint falls off, and the siding gets smelly, moldy and begins to decay (Photograph 3). Huh? The insulation did this? Yup. The drying potential is reduced due to the addition of the insulation so that the moisture entering the cladding assembly from the exterior due to rain and capillarity does not evaporate and this is further exacerbated by the colder siding having a higher local relative humidity and thus a higher equilibrium moisture content due to the sorption properties of wood. Bummer. How to fix this? Easy, wedges were used to create a gap at the overlaps of the siding reducing capillary uptake at the laps and increasing evaporation despite the cladding being colder (Photograph 4). This early lesson in sorption and drying potentials taught this engineer to drain and back-ventilate claddings –especially those on highly insulated assemblies (Photograph 5).

Photograph 1: The “Typical House”—Built in 1965 in Cleveland, OH with no cavity insulation in the exterior wood frame walls. No problems for twenty years. Insulation added to exterior walls in 1985 and within one year the paint begins to fail.

Photograph 2: Retrofit Cellulose Cavity Insulation—Dry blown cellulose packed into exterior wood frame walls. Injected from the exterior at top of cavity. This author, very young at the time, amazed at how well the insulation worked. Cavities were dry when opened.

Photograph 3: Wet Cladding—Problems with mold and decay were worse on north and east elevations. Problems with peeling paint were worse on west and south elevations. Solar radiation cycled the cladding moisture content more on the west and south elevations stressing the paint. UV cross-linked the paint making it less flexible. Less flexibility, more movement on the south and the west led to the peeling paint. Less energy on the north and the east led to the mold and the decay.

Photograph 4: Wedgie—So simple and so obvious. After the problem is understood. Wedges created gaps that reduced capillary uptake of surface water, promoted drainage and back ventilation.

Photograph 5: Drainage and Ventilation Matt Behind Cladding—This is easy for new construction and re-cladding. Existing buildings are going to be a problem. Don’t say you weren’t warned.

Let’s extend this discussion to cavity insulation in general. The same thing happens to the cavity side of sheathing when we insulate cavities. It gets worse when the cavities also have no air flow or convection.3 Sheathings get colder. If the sheathing is hygroscopic, its equilibrium moisture content also goes up. Why take the risk? Insulate on the exterior of the sheathing. This makes the problem go away. The risk is so high in cold climates that folks are no longer insulating the cavities in steel stud walls in places like Ottawa and Montreal—all of the insulation goes on the outside.

This is why insulating sheathing is pretty much the name of the game for highly insulated wall assemblies—or at a minimum claddings should be back ventilated and back-drained—or better, do both. This is easy for new construction. The problem is what to do with the existing building stock? What are we going to do if oil ever goes above $100/barrel? Dumb comment. Yes, but now we have a real problem. Folks cannot just go and blow/spray/fill cavities with a bunch of insulation without appreciating the consequences. This is not just a cold climate problem. It is a problem everywhere. In fact it gets worse when we go far south. Read on McDuff…

Reduced Heat Gain

I am going to let you in on a little secret that us mechanical engineers don’t often share with the rest of the world—air conditioning systems only dehumidify when they run. Yup, when they don’t run, they don’t dehumidify. If there is no load, there is no dehumidification.4

Well, just make them run longer. How? They still make the air cold no matter how you run them. That is good if you need cold air. But what if you don’t need cold air? What if you only need dry air? Well, you still have to make the air cold to get it to drop its water, and when you are done you still have cold air. So now what? Well, you have to heat it back up if you want to use it. This is sometimes called cooling with re-heat. There are other tricks we can do—read on—but at the end of the day we have to add energy back to the air that we cooled. There is no other practical way to do it.

It gets worse when we over-ventilate with humid air—especially when it is cloudy and not so hot. Now all you are doing is bringing in moisture. But you are doing it when there is not much of a load—not much of a “sensible load” (heat gain across the enclosure and heat gain from lights and appliances and people—the load you can “sense”) to run the air conditioning system. This moisture that you are bringing in with the ventilation air is also a “load”—but it is a different kind of load that we have pretty much been ignoring up till now and getting away with it. The operative phrase to note is: “getting away with it.” Mechanical engineers like me call this the “hidden load” or the “latent load” (as in “latent defect” or “hidden defect”) and our heads explode when we try to explain this problem to the indoor air crazies who think that only dilution is the solution to indoor pollution. I mean how can too much outside air be bad?5 Arrargah…

To take the water out of the air you need to use energy. To make the air comfortable/useful the air can’t be too cold after you have taken the water out of it. Typically heat (energy) has to be added back to the air. Traditionally this heat (energy) was available through lousy glazing systems, too much glass, black roofs with no insulation, poorly insulated walls, energy inefficient lights, and crappy appliances. Well, this traditional “re-heat” due to inefficiency and poor practice is disappearing. Now we are stuck. If we don’t warm up the air after we dry it we are going to get into trouble. We haven’t been, and we are getting into trouble. The buildings are now getting too cold or too humid or worse, both.

Ah, this is easy you say. Just make the air conditioning systems smaller—“right size” them. Don’t make me scream. I am getting tired of being told by energy weenies that my equipment is too big.6 I still have to satisfy the “full load” requirement. If you make the equipment too small it doesn’t satisfy the cooling requirements under full load. Let the people be uncomfortable you say. People should suffer you say; we have had it too good you say. Yeah, sure, another greenie weenie value judgment that also makes me scream. I don’t think we should suffer. I like it being good. I don’t have a problem with using energy. I have a problem with wasting energy. Until now we have gotten pretty good at dealing with this part-load problem with face-bypass, run-around coils, hot gas bypass and heat pipes but we have reached our limits.

Building enclosures have gotten so good, glazing systems so good, interior load management so good, that we can’t use the same equipment to handle the “sensible load” and the “latent load.” Did I mention just how good the glazing systems have become? Did I mention the low SHGC thing? We used to just install air conditioners and only cared about making it cold inside. We used one piece of equipment to handle the sensible and latent load. The reason this worked is that the latent load was small compared to the sensible load. Not any more. The sensible load has gotten smaller big time. And, much to my chagrin, the latent load has gone up due to over ventilation. The old systems can’t handle the new sensible to latent ratios. We have to separate the two loads.

We need separate systems for the sensible load and the latent load. This is a big deal and it results from the low heat gain in the modern enclosure. In other words energy conservation and good construction practice is biting us on the butt. We sometimes refer to this second separate latent load control system as supplemental dehumidification—and we need it when we have a low heat gain enclosure and efficient lighting and appliances. Others call it “preconditioning” of outside air since the largest component of the latent load is the ventilation air or the outside air. Whatever you call it, we need this second system. We don’t often get it and it hurts us.

But, but these systems use energy. Yes, as the saying goes—there is no thermodynamic free lunch. You need to use energy to make air cold and you need to use energy to make air dry. We have been very good at making air cold. We now have to get good at making air dry. Think of it this way. For every 100 units of energy you save on the efficiency and on the cooling side, you are going to have to give back about 20 units of energy to be dry. You are still 80 units ahead. Problem is, if you are greedy and want the entire 100 units your building fails and your occupants get very uncomfortable and probably very annoyed.

It is pretty amazing to me but the hotel industry figured this out first. They pretty much had the problem first, so it stands to reason that they would also figure it out first. Think about the typical hotel room. The drapes are pretty much closed all the time, the room is empty during the day, and you know the unit has been sized for the full load, with the drapes open, and the room full, and everything on and you know that someone in some bureaucracy somewhere wants way too much outside air. Most of the time your latent load dwarfs your sensible load. So what do you do? You reduce the amount of outside air by installing timers on the exhaust fans and you pretty much ignore the faceless bureaucrat. Then you only run the through-wall unit to control the temperature (i.e. make it the “sensible” system) and install a dehumidifier in each unit to control the humidity (the “latent” system) (Photograph 6). A pretty primitive but effective “fix.” In new design we just “hide” the dehumidifier better—or better still make it part of the ventilation system.

Photograph 6: Hotel Room Fix—The through-wall unit controls the temperature (the “sensible” system). The dehumidifier controls the humidity (the “latent” system).

Guess where this technology is now making an impact—condos and apartments. Small houses are next. We are already separating the latent from the sensible on most commercial design—after all it is the sensible thing to do.

North versus South

So how come it is worse in the south than the north? Besides the south losing the Civil War? In the north, it still gets cold and the outside cold air is pretty dry—and walls tend to dry to the outside in the north - so the size of the moisture drying “sink” so to speak—has not changed. But in the south, walls also dry to the inside—and if the inside is humid because of the part load problem—the walls stay wetter because the moisture drying “sink” is smaller. Additionally, in the south the moisture drive from the exterior into the wall is greater while at the same time the moisture drive from the wall into the interior is smaller as compared to the corresponding drives in opposite directions in the north. Let me translate. It is easier to get wet from the outside in the south than it is from the inside in the north. It is also easier to dry to the outside in the north than it is to dry to the inside in the south. With less energy available, it gets worse in the south faster than in the north.

Good air conditioning design leads to dry interiors and dry interiors allow walls to dry to the inside. Part load humidity problems lead to wetter walls. Higher levels of thermal insulation and lower heat gain lead to part load humidity problems. Not good.

Now What?

OK, everybody relax. We want and we need much higher levels of thermal control (air tight, insulated assemblies) everywhere. We just have to be smart about it. We want and we need ultra efficient glazing, lights, appliances, and reflective surfaces everywhere. We just have to be smart about it. And we want and we need the right amount of outside air whenever we need it. We just have to be smart about it. This is neither expensive nor difficult, just different. We have to modify our building enclosure and mechanical system paradigms. Get used to it or be steamrolled by the change.

Insulate on the outside. Back ventilate and drain your cladding. Separate your sensible load from you latent load. Don’t over ventilate. Existing buildings are going to be a bear. And have a nice day.

Footnotes:

Yes, I know, pretty arrogant for a relative youngster to say. I am in my 50’s, but when you get to this age you spend as much time looking back as you do looking forward. My mentors tell me that it helps with perspective. It has been said that in order to understand the future you have to understand the past. I am not so ambitious. I am only thinking of today. I think in order to understand the present you have to understand the past…

Someone once said that 80 percent of all building related durability problems are due to three principal damage functions (water, heat and UV radiation) with 80 percent of the 80 percent being water. I don’t know who said this. Can someone help me out? I might have just made it up, but I have been saying it so long I no longer remember if I did or not. Aren’t footnotes great…

Air flow—air change and convection—increases energy exchange therefore increases drying potential. My Canadian friends' heads are now going to explode because they have been taught that air leakage leads to “wetting” from interior sources. Yes, in extreme climates with high interior moisture loads. Think humidified buildings in Canada. Not everywhere else. Come visit the United States, the dollar exchange now works for you and air leakage improves drying potentials.

Sensible load. I know you knew that I knew this, but some of the emails I have been getting from you folks have been quite picky, which is good, but I want to head off the obvious emails, so continue to be picky, but not on this…

Some folks don’t seem to care about the energy thing either. I mean health is paramount and we should always err on the side of caution. How can we argue against health? Easy, when the “healthy” measures are “unhealthy.” Over-ventilation can be unhealthy—and energy wasteful. Read on. This is leading to interesting discussions in the Standard 62 committees. Apparently the Standard 62 committees are not about energy. Apparently energy security is not a 62 problem nor is climate change nor are operating costs. Apparently, it is some other committee’s problem. How about the energy committee (Standard 90.1)? Except that the energy committee does not want to touch ventilation. Cowards. My insider’s perspective (on 62.2 at least) is that there is a lot of mileage to be made by scaring people about under ventilation, and folks are rising to the occasion. Unfortunately, over ventilation in hot humid climates and in mixed humid climates has led to more indoor air problems due to mold resulting from part load issues than under ventilation anywhere else—in my not so humble opinion. And speaking of health and under ventilation where are all the dead bodies? Where is the causal link between health and specific levels of specific indoor contaminants? In my not so humble opinion all of the rates have been just wild assed guesses without a sound epidemiological basis. But the resulting mold from over ventilation is real and demonstrable. Just to make it clear, I have been guessing at “rates” as well, but I have not been afraid to call them “guesses” or tried to hide the guesses behind a lot of bad science. And one more thing, this LEED stuff is making me crazy, the part where you get extra points when you ventilate at an even higher rate than what Standard 62 calls for…what a bunch of green sustainability hypocrisy…doesn’t anyone at the US Green Building Council know anything about energy and part load humidity?