BSC collaborated with Greencraft Builders in Lewisville, TX on a 2009 prototype house called the TimberCreek Net Zero Energy House. This house demonstrates the energy efficiency and durability upgrades that Greencraft has been promoting for years. The architect for the TimberCreek Net Zero Energy House was William Peck and Associates, out of Lewisville, TX. The TimberCreek Net Zero Energy House is located in Lewisville, TX.

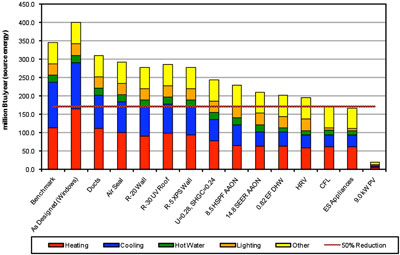

This was Greencraft Builder’s first attempt at a Zero Energy house. The strategy for achieving zero net energy was to lower building consumption through a high efficiency enclosure and mechanical as much as possible and follow up with a photovoltaic installation to generate the remaining amount of energy needed to operate the building over the course of a year.

BSC provided consulting services for Greencraft and recommended numerous efficiency and durability improvements. Key upgrades include an unvented roof with low density spray foam insulation and supplemental dehumidification. Other upgrades that contributed to increased building efficiency and durability are LoE3 next generation spectrally selective glazing treatment and a high efficiency HVAC system.

Project Team: Greencraft Builders, LLC, Building Science Corporation

Location: Lewisville, Texas

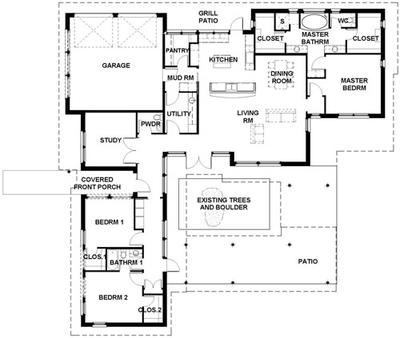

Description: 2,409 ft2 one-story single family home

Completion Date: November, 2009

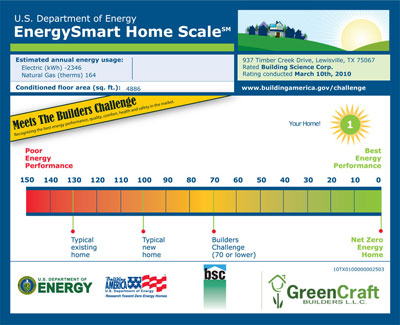

Estimated Annual Energy Savings: Average 53% projected source energy savings relative to the 2009 Building America Benchmark

Project Website: http://timbercreekzeroenergyhouse.com/index.html

Design

Greencraft employed full advanced framing throughout the enclosure. This includes 2x6 at 24” o.c. with stacked framing through the floor joists and roof rafters. A single top plate and 2 stud energy corners minimize thermal bridging in the wall system. The wall and roof are insulated with low density spray foam. One-half inch OSB sheets are installed at the corners for structural integrity. One-inch foil-faced polyisocyanurate is installed as insulating sheathing on the walls. Tyvek® ThermaWrap™ is installed over the insulating sheathing and serves. The enclosure does not contain any impermeable components and this allows accumulated moisture to dry out via vapor diffusion and prevent wetting and subsequent mold.

The TimberCreek Net Zero Energy House was able to procure, with help from BSC, vinyl framed windows with state of the art LoE3 spectrally selective glazing coating. This resulted in an NFRC SHGC rating of 0.28 as well as a U-value of 0.22. This glazing coating, coupled with extensive overhangs in the floor plan, results in a greatly reduced cooling peak load and annual cooling energy use.

Builders Challenge certificate

Enclosure Design

Roof Insulation: Unvented roof with 8.5” R-30 open cell spray foam and fully adhered waterproofing membrane under a standing seam metal roof.

Open cell spray foam in unvented roof

Wall Insulation: Fully advanced framed structure; R-25 wall with R-20 open cell spray foam and 1” foil faced polyisocyanurate sheathing.

Foil-faced polyisocyanurate sheathing

Window Specifications: Fiberglass framed LoE3 double glazed windows: U=0.28, SHGC=0.22.

Air Sealing: The design infiltration rate is 2.5 in2 leakage area 100 ft2 of enclosure area. Low density open cell spray foam installed in wall and roof cavities. Low expanding open cell spray foam installed around windows and mechanical and electrical penetrations throughout the enclosure.

Installing low density open cell spray foam

Foundation Assembly: Slab-on-grade foundation; uninsulated with Termimesh® termite mitigation system and sill gasket between framed wall and slab.

Mechanical Design

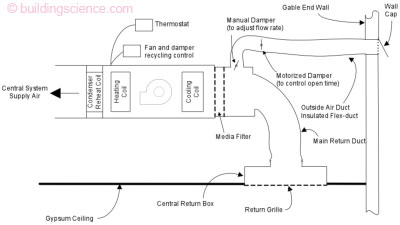

One of the major design upgrades for this house will be the installation of a heat pump with integrated supplemental dehumidification. AAON Inc. has designed a residential heat pump that integrates a modulating gas reheat coil to allow for dehumidification separate from cooling. This technology has been implemented successfully in commercial buildings for years and now will provide supplemental dehumidification in residential buildings.

The entire duct system is located in the unvented conditioned attic is sealed extremely tight. Jump ducts provide passive returns from the bedrooms. High efficiency exhaust ducts are installed at all the bathrooms and at the kitchen hood.

Heating: 8.5 HSPF heat pump

Mechanical system design schematic

Cooling: 14.8 SEER heat pump

Supplemental Dehumidification: Modulating hot gas reheat coil added to air handler to allow for dehumidification separate from cooling.

Dehumidification system installed

Ventilation: Central Fan Integrated Supply Ventilation controlled by Aprilaire 8126 Ventilation Control System (VCS).

Aprilaire VCS controller and motorized damper

Return Pathways: Jump ducts at bedrooms.

Ducts: R-8 flex ducts in unvented conditioned attic; leak free to outside (5% or less)

Ducts in unvented conditioned attic

DHW: Natural gas 0.82 instantaneous gas hot water heater

Appliances: ENERGY STAR® dishwasher, refrigerator and clothes washer

Lighting: 95% Energy Star CFLs; 5% LEDs

LED lights in kitchen and dining areas

Ventilation

Greencraft Builders, LLC utilizes Central Fan Integrated Supply ventilation that draws outside air via a 6” flex duct to the return plenum of the HVAC system. This allows for the introduction of outside air to the living space whenever space conditioning is already operating. An Aprilaire® Ventilation Control System 8126 communicates with the air handler to employ fan cycling. Fan cycling will turn on the fan at a 33% duty cycle (10 minutes on, 20 minutes off) in order to provide outside air during periods of no space conditioning. A 6” mechanical damper is installed on the 6” outside air duct. This is controlled by the fan cycler and will close off the outside air duct during periods of consistent space conditioning to prevent over ventilation of the living space.

Bathroom exhaust fans plus a kitchen hood are installed to provide spot ventilation when necessary. These are all routed to the outside and are not re-circulating fans. One of the bathroom fans is rated to provide ASHRAE 62.2 ventilation so that the house can be operated at that rate if needed.

Quality Control

Design follows BSC Building America criteria

Manual J8 analysis ensures right sized mechanical systems and ductwork

Testing

Testing and commissioning of the building enclosure and mechanical systems was performed to ensure the house will operate as designed. The following tests were performed:

Air leakage

Duct leakage

Local air flows

System external static pressure

Outside air duct air flow

Proper configuration of fan cycling control

Monitoring

BSC is actively monitoring the performance of the AAON HVAC air source heat pump with reheat supplemental dehumidification.

Design and Construction ChallengeBSC and Greencraft attempted to integrate slab insulation at the Lewisville house. The typical design of exterior insulation with a covering at the slab edge was not allowed. Local code forbids the covering of the exterior slab edge such that termite activity can be observed easily. An attempt was made to integrate 2” of vertical XPS embedded in a monolithic slab design, but there is a need for extensive reinforcement through the XPS due to expansive soils. BSC recommended replacing typical reinforcing bars with fiberglass ties in order to reduce thermal bridging losses through the vertical XPS. Another problem is that the structural design did not allow for the XPS to extend from the top of the slab down to the bottom of the grade beam. Time and budget constraints prevented resolution of this technology barrier Lessons Learned

|