I remember sitting around listening to stories my dad and his friends would tell when they were hanging around in the basement playing cards. They would laugh uproariously, tease each other, get serious sometimes, and tear up when they were telling stories about the old country and the war and friends that were no longer around. I kept telling him he should write them down, but he never did, and I never did, and then he was gone.

Not too long ago I was hanging around with some friends in a bar in Denver drinking scotch and telling stories. The laughter was loud, the teasing was good-natured, some serious things got said and a lot of truths got stretched. It was late and they told me I should write some of them down. I remembered Dad and said that I would mostly to shut them up so I could go to bed in peace. Well one of them called me a couple of days later and asked if I had written them down. He said if I didn’t he would. Well he has a blog and he gets most things wrong and I couldn’t risk that.2

In 1978 I was 23 years old. I was a builder. I thought I was one anyway. My dad was a builder and an engineer and he taught me stuff. I learned building from him. I of course was smarter than he was. I got my own engineering degree and left him and went out on my own because who would ever want to work for their father?

One evening in early December of that year I ended up at a Home Builders Association meeting listening to some old guy talking about walls. I couldn’t believe the stuff he was saying. I called him on it. He pushed his glasses down his nose and looked at me with a look of bemusement and replied: “Sonny, when you finally learn your high school physics you can come and sit with the big boys.” Just as I was going to do I don’t know what another guy gingerly put his hand on my shoulder and gave me a look that said come with me. Kind of in shock I went out into the hall with him. He said: “Gus is like that a lot. Let me get you a drink.” I followed him up to his room and he poured me a scotch. It was a single malt. I had never had one. He handed me a book.3 “You should read this”, he said. “That guy that you wanted to punch out wrote it with a guy who told him a long time ago the same thing he told you. The book hasn’t come out yet. This is a draft. I have another copy. Give it back when you are done.” I figured if I was drinking with him I should at least know his name. I asked him who he was: “John Timusk, he replied.”4

I couldn’t put the book down that night. It kept referencing the Canadian Building Digests. I read them too. The one guy, N. B. Hutcheon was some real smart guy. He headed the Division of Building Research of the National Research Council of Canada. The guy I wanted to punch out, G. O. Handegord was also real smart and from the same place. What was a guy like Handegord doing at a Home Builders Association meeting? I couldn’t believe I almost punched him out.5 They sure knew walls. Roofs, too. Windows. Airtightness. Energy. Everything. I had a mechanical engineering degree and I thought I knew stuff but I knew none of this. But I could understand the language. I read and learned. The buildings I was going to build and design forever changed that night. It pays to go to Home Builders Association meetings. Really.

Put the insulation on the outside and make the building tight. Made sense. Problem was no one was doing it. Not where I was building, just outside of Toronto. No one doing things never stopped me before. Did I mention I was 23 and invincible? In the beginning of 1979 I started a bunch of houses based on Hutcheon’s CBD-50 “Principles Applied to a Masonry Wall”, first published February 1964.

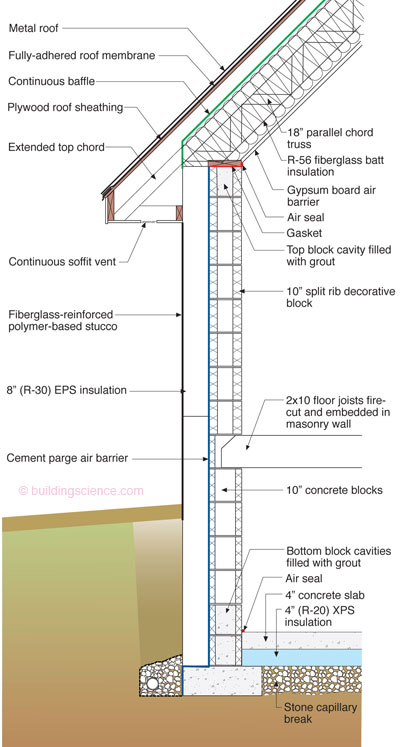

The building section I sketched up for the first one was pretty straightforward based on today’s thinking (Figure 1). But then? I couldn’t even get a building permit. It was too weird for the first building official I went to. I wasn’t a licensed engineer yet, so I couldn’t go that way. I had to build it in a place where there wasn’t a building department. Up near Bancroft, Ontario. God’s country. It wasn’t the end of the world. But you could see the end of the world from there. A three-hour plus drive there. Coming back was even worse. There and back every day? Fun. You want to ruin your marriage do that for a while.

Figure 1: Perfect Masonry Wall - Too weird to build in 1979 except way out of town. Continuous exterior insulation and an airtight enclosure.

Even though the section was easy enough to come up with. Building it was another story. The roof truss was unusual for the time but I found an old truss engineer who adopted me, did the truss design and sealed the truss drawings. So far so good. Then it got weird. How to attach 8 inches of foam insulation to the outside of a block wall? OK. Time to suck it up and eat humble pie. Time to go see Dad. He was an engineer before he was a builder. Howard Hughes was his hero. He never bought anything new. Fixed things. He made everything himself. I grew up with a machine shop in the garage and a partially built single seat jet helicopter in the basement. Not making this up. He said smart people write things in books for us stupid people if we were smart enough to read them. No kidding. The trick is to find the right book. And I had. And I had found smart people.

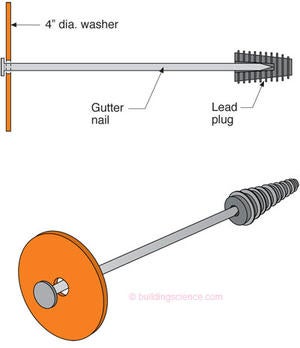

He just sat down and looked at me and didn’t say a thing. Dad was like that. Most guys of his generation were like that. He was a fighter pilot during the war. The ones that lived would go quiet a lot. The ones I knew anyway. I met a bunch of them through Dad. Not once did he ask why I wanted to do it. He just worked the problem. After about an hour he got up without saying a thing and I followed him to the car and we drove to Canadian Tire. He got a long masonry drill bit, some gutter nails, a bunch of really big washers and some lead plugs. He sketched out the solution on a pad of paper. I wish I had kept the sketch. Worked like a charm (Figure 2).

Figure 2: Dad’s Fastener - Gutter nails, a bunch of really big washers and some lead plugs. Put the nail through the washer. Push the lead plug onto the end of the nail. Lean the rigid foam against a masonry wall. Drill through the foam with a 5/8-inch diameter long masonry bit 1-inch into the masonry wall. Pull the bit out of the opening. Insert the fastener through the foam “pilot” hole so the lead plug engages the hole in the masonry. Use a mallet to hammer the fastener home.

How many would I need? How far apart? Dad gave me “the look”. The look I had been getting since I was in short pants. Build a wall and you will know. He was a flight test engineer at DeHaviland. He was an old school engineer. I was his son. I knew what to do. Mock ups, test walls, experiments. The Wright brothers were his role model. His sketch book and his slide rule were part of him. He was my role model. I built a test wall and tested it until it broke. Six fasteners for every 4 ft x 8 ft sheet of insulation. Two at the top, two in the middle and two at the bottom. Eight inch thick foam. No way that would work. Except when you built it, it did. You could hang a pickup truck off that wall.6

Then it got weirder. The cladding. It was going to be stucco. Even with my limited building experience, I already hated stucco. Dad hated stucco. This was Ontario. We don’t build stucco walls. Except when we do. The client wanted stucco. He was going to get stucco.

I went to see John Timusk. He was “JT” to me by then. He started talking to me about the concrete canoe club at the University. I rolled my eyes. Those undergraduate civil engineering students were always hitting up us engineering science students for cash to fund their dumb ass competition entries in the international concrete canoe thing. I was away from the University less than 4 months and here I am hearing about these losers again. But JT loved his stories. If you listen to them you actually learn stuff. So I listened. Apparently you can make very thin shell concrete canoes with fiberglass cloth and Portland cement paste and latex polymer and ammonia and the Germans were already ahead of us putting it up as a thin cladding on foam on the outside of buildings. It was lightweight and it had tensile strength. I liked it. JT had my attention.

He took me down to the Gardiner Expressway7 where they were using it to fix and patch the concrete supports and concrete deck. He made sure I understood that the fiberglass cloth needed to be treated to handle the alkalinity of the mix or that the mix had to be buffered. I asked him how he knew. He handed me another book. “Properties of Concrete” by Adam Neville. He started to say something. I waved him off. “I know, I know, give it back when I am done,” I said.

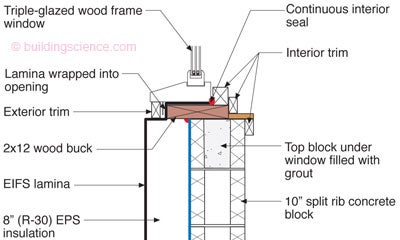

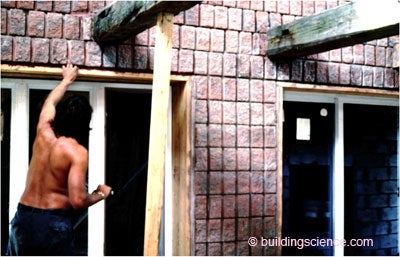

So I mixed up a batch and did a test wall. Awesome. There was no Sto or Dryvit around yet. I hadn’t met John Edgar yet. I was in the EIFS8 business before there was one. I was getting my chemicals from the guys fixing the expressway and using the mix design from the guys in the concrete canoe club. So how did I avoid all those EIFS problems that came a decade later? Easy. I wrapped my EIFS lamina into the window opening and then installed the window (Figure 3). I also had a water control layer behind the foam. And I had a masonry wall. And I had the CBD’s. Especially CBD-40 “Rain Penetration and its Control.” Kirby Garden’s classic, first published April, 1963.

Figure 3: Avoiding EIFS Problems - I avoided all those EIFS problems that came a decade later by wrapping the EIFS lamina into the window opening and then installing the window. The lamina acts as an under window “gutter.” A stucco “pan flashing.”

Was I really that smart? No. I was very lucky. When the problems of EIFS started popping up in the late 80’s I already knew the score because I had done stuff with synthetic stucco that worked, I understood water management because I was learning at the feet of the masters, or at least reading their stuff and I compared it to stuff that I was seeing that didn’t work. The failures I was seeing explained to me why what I had done worked and why it was consistent with what I had read. It is often better to be lucky than smart. It is even better if you know smart people. And I was meeting them in spades.

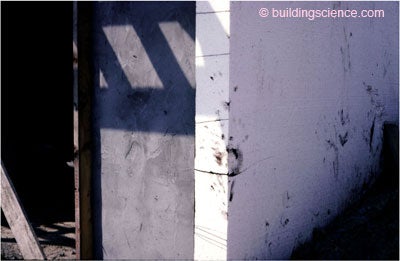

Finished the first one fall 1979 (Photograph 1). Continuous exterior insulation (Photograph 2). Beautiful split ribbed concrete block interior with timber beams (Photograph 3). Triple glazed windows. Airtight. Heated by a wood stove in the basement. No ducts, just transfer grilles in the floor. Old school. We used to do that before there was forced air. Combustion air ducted to the wood stove. Also had a fireplace. Combustion air ducted to the fireplace too. Got one of Greg Allen’s9 first air-to-air heat exchangers. Build tight, ventilate right. Doing it before Jim White coined the phrase.

Photograph 1: God’s Country 1979 – Super insulated continuous exterior insulation, triple glazed windows, airtight and ventilated right.

Photograph 2: Air Control Layer – Cement rendering is the air control layer. Mechanically attached 8 inch thick expanded polystyrene (EPS).

Photograph 3: Interior Finish – Split rib decorative block with exposed structural timbers.

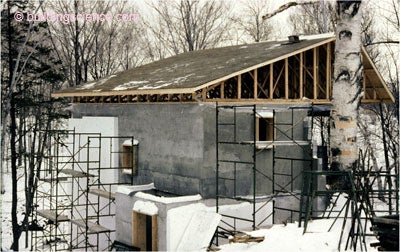

Built another one in Collingwood, Ontario the next year. Used “energy trusses” before there were energy trusses (Photograph 4). My old truss engineer said it was dumb to squeeze the insulation at the roof perimeter. He sketched up his idea on a napkin. Another napkin I should have kept. The rigid foam on this one went up “slick as snot on a glass door knob”10 (Photograph 5).

Photograph 4: Energy Trusses – “High heel” trusses and a R-60 vented attic with an airtight lid.

Photograph 5: Exterior Rigid Insulation – Large plastic washers and mechanically attached 8 inch thick expanded polystyrene (EPS).

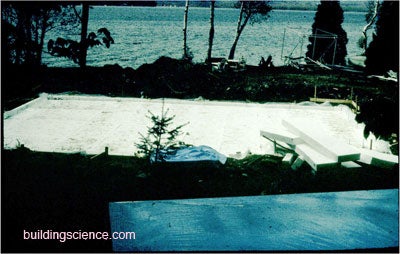

I had a system and it was working. I built a couple more in 1980. Problem was it was expensive. And it was slow. Needed to make this work with wood. I got a chance to give it a shot in the Eastern Townships outside of Montreal in 1981 (Photograph 6). The site was beautiful and on the edge of a lake. The site was also ugly because of the bearing conditions of the soil. I needed to spread the load. I needed a very stiff plate foundation and I needed the plate to be lightweight. And I needed a thermal break. And I needed a shallow foundation. I was a Toronto boy. The U of T had another unheralded genius, Eli Robinsky. He was a professor in the same department as JT. Professor Robinsky developed the shallow frost protected foundation that the Swedes get credit for. I actually took his class. I remembered.

Photograph 6: Go East Young Man – Wood frame perfect wall in the Eastern Townships outside of Montreal in 1981.

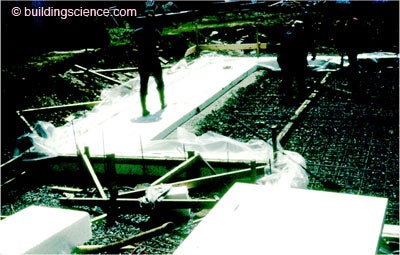

Check out Photographs 7, 8, 9 and 10. Got a crazy lunatic US engineer, Tony Karwoski, to do the structural calculations as no one I knew in Canada would touch it. “TK” wherever you are, you are my hero. Two thin reinforced concrete slabs sandwich a foam core that saves weight and acts as a thermal break. A slab on grade foundation with a high moment of inertia without a weight penalty. Stiffer than a week old corpse.

Photograph 7: Slab 1 – Grade prepared for first layer of concrete. Notice the foam form.

Photograph 8: Slab 2 – Foam core is embedded into the first layer of concrete as the first layer of concrete is placed.

Photograph 9: Slab 3 – “Foam bathtub” ready for top layer of concrete.

Photograph 10: Slab 4 – Sandwich construction of slab. Note the foam layer between two layers of concrete. A small section of the perimeter foam form was removed for this “photo op”.

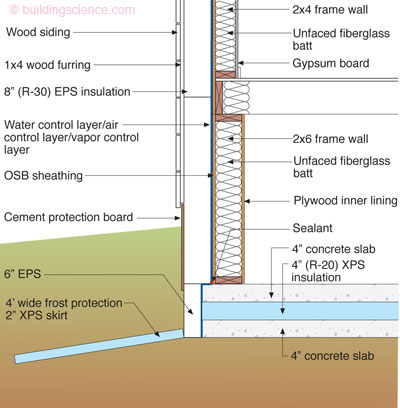

I put a conditioned crawlspace on top of the slab and used a wood frame version of Professor Hutcheon’s masonry wall. Check out Figure 4. Professor Hutcheon meet Professor Robinsky. Introduction courtesy of “TK”.

Figure 4: Perfect Frame Wall - Two thin reinforced concrete slabs sandwich a foam core that saves weight and acts as a thermal break. A conditioned crawlspace was constructed on top of the slab. A wood frame version of Professor Hutcheon’s masonry wall was used for the exterior assemblies. Professor Robinsky’s frost protected shallow foundation makes it all work. The walls were wood frame sheathed with oriented stand board (OSB). A polyethylene water control layer, air control layer and vapor control layer was installed over the exterior of the OSB. R-30 EPS (8 inches worth) was installed over that held in place with wood furring and long screws. The wood siding was installed over the furring providing back venting and drainage. I had Kirby Garden’s “rain screen”. The frame wall was insulated with unfaced fiberglass batts. An R-40 single stud wall.

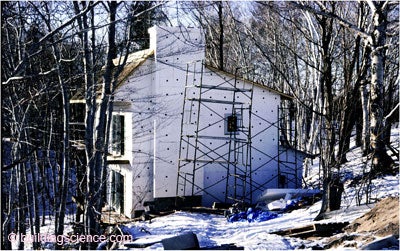

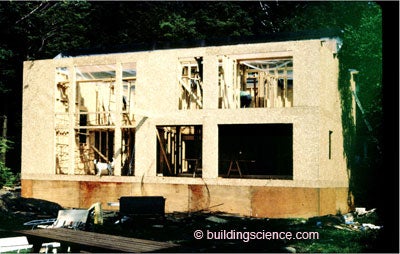

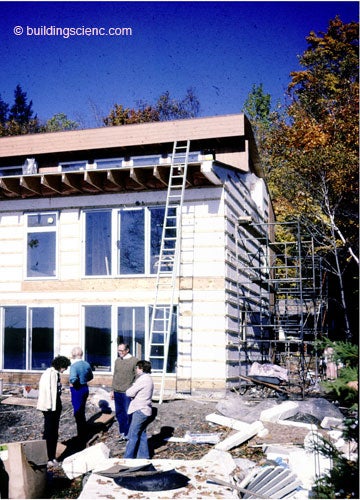

The walls were wood frame sheathed with a new product called oriented stand board (OSB) (Photograph 11). A polyethylene water control layer, air control layer and vapor control layer was installed over the exterior of the OSB. R-30 EPS (8 inches worth) was installed over that held in place with wood furring and long screws (Photograph 12). The wood siding was installed over the furring providing back venting and drainage. I had Kirby Garden’s “rain screen” (Photograph 13). The frame wall was insulated with unfaced fiberglass batts. And presto I had an R-40 single stud wall. All this was before R-2000.

Photograph 11: Frame Structure - The walls were wood frame sheathed with a new product called oriented stand board (OSB).

Photograph 12: Perfect Assembly - A polyethylene water control layer, air control layer and vapor control layer was installed over the exterior of the OSB. R-30 EPS (8 inches) was installed over that held in place with wood furring and long screws.

Photograph 13: Rain Screen - The wood siding was installed over the furring providing back venting and drainage. I had Kirby Garden’s “rain screen”. The frame wall was insulated with unfaced fiberglass batts. An R-40 single stud wall before R-2000.

Thirty years later not a lot has changed in my designs from that wall I built in 1981. I call it the “perfect wall” now. Professor Hutcheon’s brainchild really was “perfect”. The wood frame is a 2x6 now and the poly has been replaced with a fully adhered membrane. I am down to 4 inches of rigid insulation, in two layers, with the joints offset. Polyisocyanurate at that thickness gives me R-26. With the nominal R-20 cavity insulation in the 2x6 frame I have got a “R-40 ish” wall. Figure 5 shows the evolution.

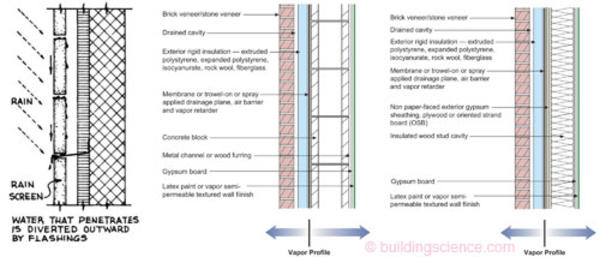

Figure 5: Perfect Evolution – Professor Hutcheon’s perfect wall circa 1964 is on the left. The masonry version constructed today is in the middle and the wood frame version constructed today is on the right.

So what happened with Gus and me? I started driving out to see him in Ottawa every other week. It was a 5-hour drive and if I left early enough I could catch him during the mid morning coffee break at the Division of Building Research. By then I was living in Dads basement again, no longer having to worry about irritating a wife. Gus always had time for me. Warmed up to me over time. I wrote a paper a couple of years later that got peer reviewed and ultimately published. Even better it was selected to be one of the representative Canadian papers at the CIB W40 Conference in Victoria, BC. I traveled to Victoria to present it. At the end of the presentation, John Timusk, who was also at the conference gave me that famous nod of his and told me to follow him to his room.

There standing in the room was Gus Handegord himself with a grin on his face holding a scotch in one hand and handing me one with his other. “Well young Joseph,” he says, “it looks to me as if you finally did learn your high school physics.” John Timusk laughs and seeing the two of them standing together gets me all teary. OK, not teary, being the big macho guy I am tears stream down my face. I then hear a voice behind me: “Someone told me I could find some scotch here.” I turn around and there is this slim distinguished looking man with an amazing twinkle in his eyes. “You must be that young man that John and Gus keep telling me about” he tells me. “You and I have to sit down and talk about wood. You really have it all wrong. But first, is that a single malt in your hand?” I nod and I ask with some trepidation because I already know where this is going to end up: “Who are you?” He winks at me and says, “My name is Don Onysko.”11

Post Script

It is not often that someone gets to meet the giants in their chosen profession and to learn from them and to laugh with them. A couple of us have been very fortunate in that regard. Me particularly. Note that I am not going to use the standing on the shoulders of giants quote here. Isaac Newton meant it as an insult to Robert Hooke who was a real short guy. Newton and Hooke really hated each other. The guys I am talking about didn’t. But they did get irritated at each other every now and then.

References

Kirby Garden, “Rain Penetration and its Control.” Canadian Building Digest 40, National Research Council of Canada, April, 1963

Neil B. Hutcheon and Gus. O. Handegord, “Building Science for a Cold Climate”, John Wiley and Sons, 1983.

Neil B. Hutcheon, “Principles Applied to a Masonry Wall”, Canadian Building Digest 50, National Research Council of Canada, February 1964.

Adam M. Neville, “Properties of Concrete”, John Wiley and Sons, 1963.

Eli Robinsky and Keith Bespflug, “Design of Insulated Foundations”, American Society of Civil Engineers, Journal of the Soil Mechanics and Foundations Division, Vol. 99, No. 9, September, 1973.

Footnotes:

You of course know that is not true – it’s a fabulous blog written by a guy with a girl’s name. His name also has a number after it. What is that about?

Hutcheon, N. B. and G. O. Handegord, “Building Science for a Cold Climate”.

Professor John Timusk, Department of Civil Engineering, University of Toronto. Retired now. Friend. Mentor. Doctorial advisor. Role model. Great father. His son Chris is a Professor at George Brown College and takes after his dad.

They were fixing it then. They are still fixing it. It should have been taken down a long time ago.

EIFS stands for “exterior insulation finish system” also known as “synthetic stucco”.

Greg Allen is one of those quiet geniuses who has not gotten the recognition he deserves. University of Toronto grad. Same program as me, Engineering Science, graduated a decade earlier than me, and much smarter. We never became real friends probably because I went out of business before I paid for those first heat exchangers he made.

Canadian expression from the farm country around Waterloo, Ontario.

Dr. Don Onysko passed away last month. He was the best wood guy in the world. He was at Forintek for many years. His legendary knowledge was only exceeded by his generosity, kindness and grace – and fondness for single malts. His tiny physical stature and wisdom earned him the nickname “Yoda” from the generation of Star Wars youngsters whom he mentored. We miss you Don.