I love wine. People think that I must know something about the stuff because I drink a lot of it. I don’t really know that much, but I do know what I like: red, and French and with a cork. Most of the questions I get, I have no clue about, and so I make up stuff—I am a consultant after all. Mostly, I know the answers to questions about how to store the stuff. That is, I know whom to ask about storing the stuff.

If you want to know something about wine just ask the French.1 Here is the magic information you need to know about storing wine: 55 degrees F at 70 percent relative humidity. Where does that come from? Old French guys. That is not the temperature you should drink it at, but the temperature and relative humidity you should store it at. And we are talking bottles here, not barrels. Drinking temperatures are more difficult to pin down. I like 65 degrees F for Bordeaux—but there is no consensus, it varies by type of wine and by nationality and most folks are lunatics about the drinking temperature part.2

It is clear that the colder you store wine (and most other things) the longer it will last. The Arrhenius equation tells us why. So why not colder? Ah, we actually want it to “age” and that means we want some chemical reactions to continue to happen in the bottle for a long time. If it is too cold these reactions don’t happen. There is a difference between “preserving” wine and “aging” wine.

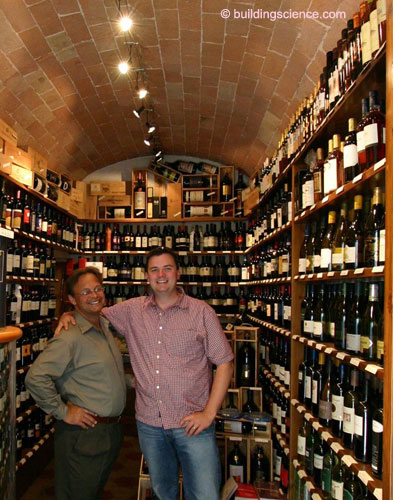

It really is a “Goldilocks” thing, not too hot, not too cold, but just right. How did the French pick 55 degrees? Tradition mostly. Wine was stored in cellars—that is why we call them “wine cellars.” Who knew? If you have a big old-fashioned French Chateau handy (Photograph 1) you will find that the temperature in the cellar is about 55 degrees.

Photograph 1: French Chateau—A nice place to store wine is in its cellar.

What about relative humidity? Notice, earlier I said “bottles.” Most of the wine in the Chateau’s starts out in barrels (Photograph 2). Drinking out of the barrel is complicated—you can’t move them easily to the dining room and so you need a guy with a “thingy” that extracts the wine directly from the barrel (Photograph 3) and squirts it immediately into a waiting glass (Photograph 4). The French, being the innovators they are, figured bottles made from glass—small enough to carry—would be more convenient.

Photograph 2: Cellar for Barrels—Barrels need higher humidity conditions than bottles.

Photograph 3: Professional at Work—I just love this picture. Note the mold on the walls. No respirator and bio-suit.

Photograph 4: Other Professionals—Famous ASHRAE member checking on the quality of the wine. Mr. Gary Nelson finds time away from his Standard 62.2 interests.

So why not put the wine right into glass bottles right away? Not so fast. The barrels are made out of wood and the wine needs the wood for it to be able to taste like wine. OK, the wine needs the wood for it to taste like good wine.3 The type of wood the barrel is made out of is a big deal. Oak is the wood of choice. French oak is preferable for French wine, American oak is preferable for American wine, Slovenian oak is preferable for Italian wine . . .

Back to the barrels, the ones made out of wood, well they are not impermeable. Wood is not a vapor barrier. It is not an alcohol barrier and it is not an oxygen barrier. Water diffuses out as does alcohol while oxygen diffuses in. The diffusion outward of water and alcohol concentrates the flavors—the diffusion inward of the oxygen governs the chemical reactions.

It is important for the wine making process that the vapor diffusion outward is controlled—slowed down – but not stopped—and this is done by storing the barrels at a high relative humidity. How high? Back to the French again. What is the relative humidity in the cellar of a French Chateau?

A cellar in France is around 55 degrees F and 80 to 90 percent relative humidity. Apparently those are the ideal conditions for storing barrels of French wine. You are not going to find those conditions in a cellar in California unless you get help from an ASHRAE member. And even with help from an ASHRAE member you are not going to get identical conditions to those of France—you will get close—but it will not be the same. You are going to get California conditions in California and therefore you are going to get wine that tastes differently—it will taste like—wait for it—California wine.

French wine tastes French because it is made in France out of grapes grown on French dirt and stored at the temperature and relative humidity found in the cellars of French Chateaux in wood barrels made from French Oak made by French craftsmen the French way—staves are split, not sawn (and yes, this makes a difference). Size also matters—the ratio of surface area to volume is a big deal.

Now let us think about the consequences of temperature and relative humidity conditions relating to 55 degrees F and 80 to 90 percent relative humidity. Great for making wine and for storing wine barrels, but not so great for the space. Without fail you will get all kinds of mold (Photograph 5).

Photograph 5: Mold in Cellar—I am shocked, just shocked to see mold in a cellar. One of the reasons French wine tastes differently than California wine . .

Is this mold good or bad? The mold on the walls does not seem to be a problem. It does not hurt the wine if it stays on the walls. It also does not seem to bother the French. The French are pretty cool about mold, and health and the food thing in general. They seem to not over do the pasteurization thing with food—even though Pasteur was French. But they do seem to smoke a lot.

The problem with the mold is if the mold is cleaned off the walls with bleach. The cleaning with bleach leads to something called TCA (“2,4,6-trichloranisole”). If the TCA gets into the wine the wine becomes “tainted.” That’s a polite way of saying it tastes like crap. The French do not worry about the mold on the walls in their wine cellars that store barrels. They also never use chlorine in their wineries for cleaning purposes. Soap and water and elbow grease. Also, they tend to build them out of rocks and wood rather than paper faced gypsum board and engineered lumber. It is harder to get mold on rocks and wood than the stuff we use in North America.

In America, particularly in California, where we have a high preponderance of mold fearing lunatics, the zeal to eliminate mold with chlorine has lead to tens of millions of dollars worth of tainted wine. I love to watch the French in California especially near food or near a winery—their heads explode.4 We also put chlorine in water. It is not a good idea to have chlorinated water anywhere near a winery or a wine cellar.

What the French worry about is mold in corks. This becomes more of problem once we take the wine out of barrels and store them in bottles. We now have lots of corks to worry about. Too much humidity and we get moldy corks. Too little humidity and we get dry corks. With a dry cork, air can get into the bottle and that will lead to spoilage. Also, dry corks lead to evaporation from the bottle. That is why wine is stored “sideways” so that the wine keeps the cork wet on one side helping to maintain the seal.

So why not get rid of the cork and use something that seals better for longer? I mean the only reason we used cork in the first place is that it was the only technology that we had available at the time. Oh, wow. You want to start an argument? It is like the Designated Hitter Rule in baseball—there will never be peace between the American League and the National League. The folks who want to get rid of the cork are American League types—why use bad technology (i.e. cork) and why watch a lousy hitter (i.e. pitchers). The folks who want to retain the cork are National League types—purists and traditionalists.

So, if we have cork in wine bottles and we want to store the wine what do we do? Back to the answer at the beginning of this story: 55 degrees F at 70 percent relative humidity. The 70 percent relative humidity is just about the maximum relative humidity that we can maintain without damaging corks. It is also a pretty good humidity to keep the cork from drying out. It really is a rate thing. What is the rate of moisture entry into the cork on the wine side versus the rate of evaporation on the outside seal side? We have 100 percent relative humidity on one side and 70 percent on the other. Seems to work. How do we know? Watching lots of bottles for lots of years.

What else do we have to worry about? The label. You have got to be kidding, right? Nope, the label is a big deal. If you trash the label how do you know what is in the bottle? The value of a wine bottle is determined to a large extent by the condition of the label. At 70 percent relative humidity we are pushing the limits for damaging the label—which is paper based. Why not go to a non-paper based label? See cork above and Designated Hitter Rule.

Some folks wrap the label with sealable polyethylene to protect the label from the relative humidity (Photograph 6). In my experience, and it is limited and I am not French, limiting the relative humidity to 70 percent protects the label. Once you get above 80 percent you pretty much have to wrap the label—and that only buys you time. How much time? Years, not decades.

Photograph 6: Protecting the Label—You don’t need to do this if the cellar does not go above 70 percent relative humidity.

Photograph 7: Wine Cellar—So what should the ventilation rate be for this wine cellar? Where is Standard 62.2 when you need it? Actually, this is an interesting question. Do you ventilate or not? Yes, but very little. I re-circulate the air through a charcoal filter and don’t hang out in the wine cellar. I provide about 1 air change every two days. How? With a small balanced ventilation system on a timer.

What does 55 degrees F and 70 percent relative humidity mean for wine cellars? Well, for the French and their Chateaux it means that have to install dehumidifiers in their cellars if they want to store their wine in bottles with corks and paper labels.

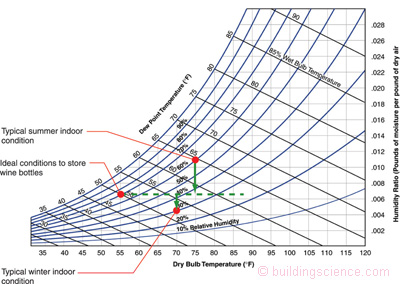

If you don’t happen to be French and have a Chateau with a cellar and a dehumidifier what do you do? You construct a wine cellar using a psychometric chart and some building science. Figure 1 shows typical indoor summer conditions, typical indoor winter conditions relative to ideal wine cellar conditions for houses in most parts of North America. Note that we have vapor flow into the wine cellar during the summer and vapor flow out of the wine cellar during the winter.

Figure 1: Wine Cellar Psychrometrics—Vapor flow occurs into the wine cellar during the summer and out of the wine cellar during the winter.

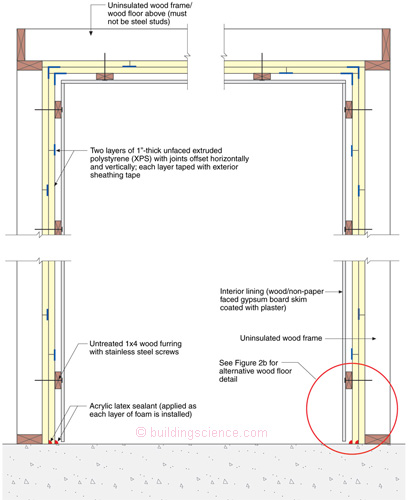

To make this work I need an assembly that handles bi-directional vapor flow. I do not like the idea of vapor barriers on both sides of an assembly that has vapor flow in both directions. I like materials that are semi-vapor impermeable and more or less homogenous. Flow is slow in both directions—but not completely eliminated in either direction. Check out Figure 2a and Figure 2b for a pretty easy way to construct a wine cellar if you don’t happen to have a cellar. If you don’t like extruded polystyrene you could substitute spray polyurethane foam.

Figure 2a: Wine Cellar Enclosure—Bi-directional vapor flow through semi-vapor impermeable extruded polystyrene. Note the back ventilated interior lining and the absence of paper based materials.

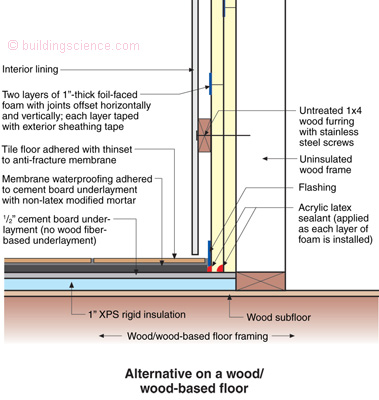

Figure 2b: Wine Cellar on Wood Floor—Note the absence of a vapor barrier between the tile and the cement board underlayment.

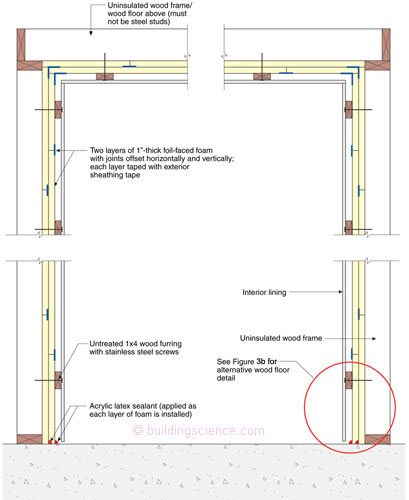

Just to mess some of you up I also provided assembly details for constructing a steam room (or a sauna)—which leads to very similar design outcomes (Figure 3a and Figure 3b). Note the two subtle differences—the steam room and sauna assembly uses foil faced rigid foam—and the steam room and sauna assembly has a waterproof membrane directly under the tile—above the rigid insulation. The wine cellar floor does not have a vapor barrier (i.e. the water proof membrane) under the tile floor above the rigid insulation as this would lead to a vapor barrier on the wrong side of the assembly for the summer part of the year.

Cheers!

Figure 3a: Steam Room or Sauna—Vapor flow is almost always from the interior of the steam room or sauna to the exterior. This is not a bi-directional flow problem. Note the very high vapor resistance lining—foil faced rigid insulation.

Figure 3b: Steam Room or Sauna on Wood Floor—Note the waterproofing membrane and flashing. This layer is also a vapor barrier.

Footnotes:

Yes I know that other folks also make good wine. However, you ask Canadians about hockey, even though other folks play some pretty good hockey, you ask Americans about baseball, even though other folks play some pretty good baseball. I have also learned that when you ask about these things you should ask the older, more crotchety opinionated ones that wear natty suits the difficult questions . . . well that’s true about hockey . . . with wine questions the suits don’t matter . . .

ASHRAE legend Ollie Fanger carried around a gold thermometer with him wherever he went to make sure the wine he drank was at precisely the correct temperature. I never got to drink wine with the great Professor …. maybe I will get a chance in the great wine cellar in the sky . . .

Some wine manufactures do this part of the process it in large stainless steel vessels that they spike with wood chips. Notice I used the word “manufacturers”—these are not craftsmen—a pox on their houses . . .

Memo to the French, the rest of us also think the folks in California are crazy.