In building air barriers, the field of the opaque wall typically does not contribute strongly to the building’s overall air leakage. Instead, details that connect building components are often the cause of much of the air leakage, such as the roof-to-wall interface, wall-to-foundation interface, and other details (e.g., bathtubs, fireplaces, service penetrations).

The rim joist or band joist is a particularly troublesome detail. This condition occurs at the basement- (or conditioned crawlspace) to-first-floor interface, and between floors. The concrete foundation-to-wood sill plate connection is often the source of significant air leakage.

This area is problematic for several reasons. First, several framing components (sill plate or top plate, rim joist, and subfloor above) need to be connected with sealant as air barrier components; this application is quite workmanship-sensitive. Second, the interior side of the rim joist is a cold surface in wintertime, and has associated risks of condensation (see Condensation Control, below).

Details have been developed that address all of these issues (see below); however, they require time and care to execute effectively.

An alternate detail that addresses these condensation and air barrier details quickly and easily is known as the “critical seal”: spray urethane foam insulation is applied to the relevant surfaces, connecting them as an air barrier. In practice, our measurements have shown that this detail provides outstanding building airtightness (when combined with cavity-fill insulation above-grade walls with good airtightness detailing).

High density (closed cell, 2 pounds/cubic foot) or low density (open cell, 0.5 pounds/cubic foot) foams provide acceptable results; open cell foams might require additional vapor and condensation control measures in DOE Zone 6 and higher. Foam can be applied by a spray foam subcontractor, or by the use of small spray foam kits.

Condensation Control

The interior of the rim joist is a cold surface in wintertime; this problem is made worse when the basement walls are insulated. Conventional fibrous insulation (e.g., fiberglass batts) allows interior air to communicate through the material; as a result, condensation and mold growth can result. The “critical seal” detail minimizes the risk of interstitial condensation at this area.

Code Acceptance

The International Residential Code (IRC) allows the exposed use of spray foam at rim joists (i.e., without a 15-minute thermal barrier such as drywall), as long as the thickness is less than 3-¼” (see R314.5.11). High density (closed cell, 2 PCF) spray foams were approved in the 2003 IRC, and low density (open cell, 0.5 PCF) foams were approved in the 2009 IRC, as well as any intermediate densities.

Critical Seal Details

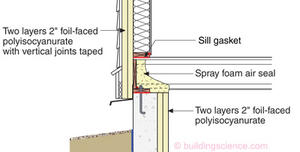

Figure 1

Cold-Climate Rim Joist Detail

- Non spray foam detail that handles condensation and air barrier issues

- Exterior rigid insulation board provides condensation control at interior of rim joist

- Caulk or sealant connection required between framing components and subfloor to maintain air barrier continuity; workmanship-sensitive application

Figure 2

Critical Seal Detail

Figure 3

Critical Seal Application at Basement Rim Joist

- Spray foam can be left exposed in basement or conditioned crawlspace application

- For air barrier purposes, spray foam must connect from foundation wall, up rim joist, and to floor sheathing

- Photo above shows basement insulated mid-thickness within concrete (foam insulation placed in concrete forms); exterior insulated basement would be similar

Figure 4

Critical Seal at Rim Joist Between First and Second Floors

- For air barrier purposes, spray foam must connect from first floor wall top plate, up rim joist, and to floor sheathing; of course, connections to remainder of air barrier system (e.g., Air Drywall Approach) must be made.

Figure 5

Critical Seal Application with Small Spray Foam Kit

Figure 6

Small Spray Foam Kit

Suggestions for Further Research:

“READ THIS: Before You Design, Build or Renovate,” Section 2a: Recommendations—Water, Building Science Practice Note 040.