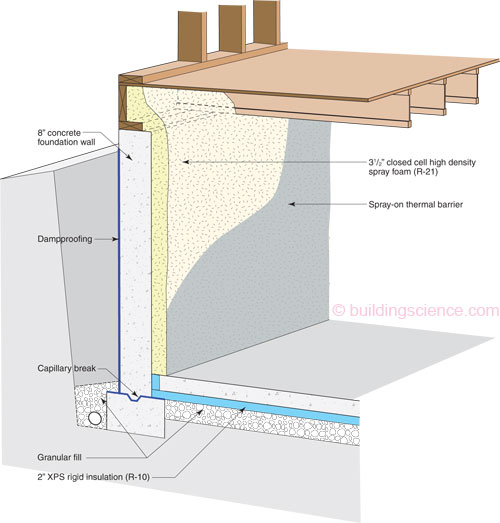

This construction uses 3 1/2" closed cell high density spray foam insulation on the interior of the rimjoist and foundation wall, and 2" XPS rigid insulation under slab. As shown below, the spray foam can be applied directly to the concrete, but if the foam is left exposed it will require a thermal barrier, typically a spray-on thermal barrier. The other option is to build a stud wall in front of the spray foam and use gypsum wall board as the thermal barrier.

Foundation Wall

- Free draining backfill

- Dampproofing to grade

- Concrete foundation wall (over a capillary break on the concrete footing)

- 3 1/2" closed-cell spray foam

- Spray-on thermal barrier

Foundation Slab

- Concrete foundation slab

- 6 mil polyethylene vapor barrier under slab

- 2" XPS rigid insulation under slab

- 4” stone pad (no fines)

- Undisturbed/ native soil

Thermal Control

Closed-cell spray foam provides very good continuous thermal control. Spray foam is an air barrier, so convective looping and air leakage thermal losses do not occur. This wall system has an R-value of R-21 and a predicted annual heating energy loss of 16.4 MBtus. More thermal control could easily be added by spraying more foam against the wall.

Moisture Control

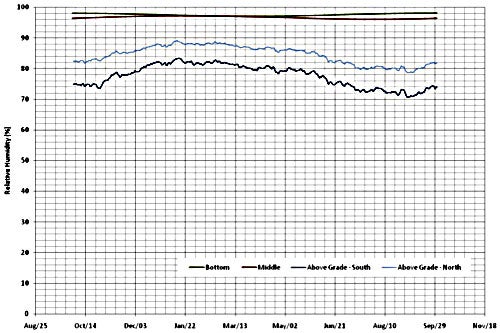

Because closed-cell spray foam is an air and vapor barrier, there are no risks to air leakage or vapor diffusion condensation. The concrete is unable to dry to the interior through closed cell spray foam, but concrete is generally not affected by a high moisture content. Figure 2 shows the relative humidity in the middle of the foam does not exceed 80%, which means there are no moisture related risks from vapor diffusion.

Figure 2: Predicted RH in the interior surface of the foundation wall of closed-cell spray foam

Constructability and Cost

In this proposed wall system, it is possible to embed the framing members in the foam (similar to High-R Foundation 10) to increase the interior space. The framing should not be in contact with the foundation wall to limit thermal bridging, and potential moisture related issues with the framing members. Closed-cell spray foam can be more expensive than other options, but reduces labour time over some of the other walls, and is applied by a skilled labourer so the system is very durable as a long term solution.

Spray on thermal barriers can add significant cost to the spray foam installation, but are region specific.

Closed-cell spray foam installed on the interior of the concrete foundation wall is the easiest and safest way to retrofit an existing basement. Spray foam can be installed in combination with a drainage matt and interior drainage tile in basements that have liquid water ingress issues.

Other Considerations

Spray foams have been improved considerably for human health and the environment. Ozone depleting substances in the process have been removed, but some spray foams use greenhouse gases that are much worse than carbon dioxide. There are options available of more environmentally friendly spray foams that do not release green house gases, such as water blown foams, on the market and should be considered.

Reference

Mitalas, G.P., Calculation of Basement Heat Loss, National Research Council Canada.