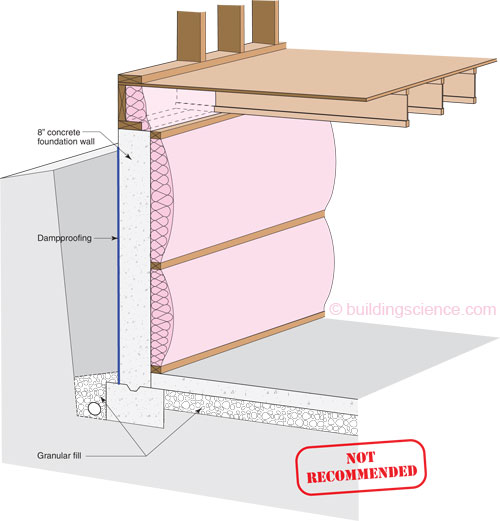

This construction uses continuous R-10 or R-13 batt insulation on the interior of the concrete foundation wall. The slab is left uninsulated and the rim joist is insulated with batt insulation. According to the IECC, new residential construction of conditioned basements in DOE climate zones 4 and greater must be constructed with continuous R-10 insulation or R-13 in a framed wall. Continuous R-10 is typically installed by applying a roll batt directly to the foundation wall which consist of fiberglass batt. In some areas, the roll batt is covered with a polyethylene vapor barrier, as was simulated in the hygrothermal analysis. In the IRC, there have been improvements to the building code which do not recommend a Class I or II vapor control layers in the basement or on the below grade portion of any wall. Commonly a perforated facer is used which is vapor and air permeable.

Foundation Wall

- Free draining backfill

- Dampproofing to grade

- Concrete foundation wall

- Continuous R-10 or R-13 batt insulation

Foundation Slab

- Uninsulated concrete foundation slab

- 6 mil polyethylene vapor barrier under slab

- 4” stone pad (no fines)

- Undisturbed/ native soil

Thermal Control

The installation of R-10 continuous insulation, even as a roll batt, has significant energy improvements over uninsulated foundations, with savings of approximately 31 MBtus (more than half of an uninsulated basement) according to simulations. Roll batt is used because it is very inexpensive and meets code, although there are other alternatives that peform better, as shown in some of the following cases. These alternatives are more expensive for the contractor, and homeowners are unaware of the benefits.

Moisture Control

There are moisture issues with this insulation strategy that are evident both in field investigations and simulations. Fiberglass batt is air and vapor permeable, so moisture and air can move through the insulation.

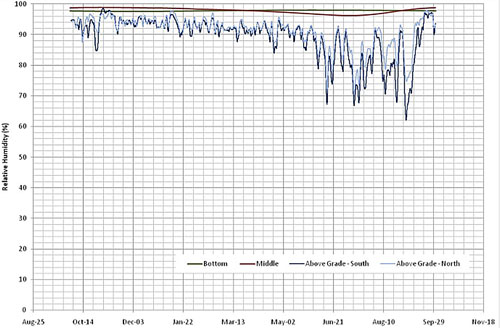

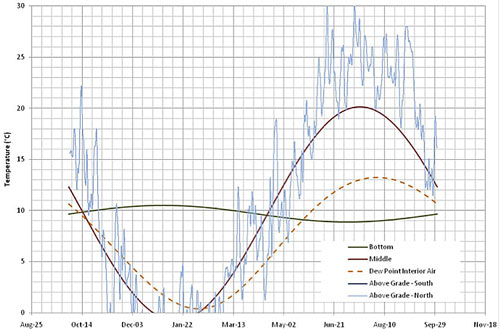

As can be seen in Figure 2, the relative humidity against the concrete foundation wall is elevated through the entire year. If there is air leakage (or the facer is air permeable) there is condensation potential on the concrete foundation through most of the year as shown in Figure 3. Because these simulations are one dimensional, they are good approximations, but heat flow in the foundation wall is three dimensional. Also, in the air permeable insulation, convective looping is likely, which may increase the condensation above predicted results. Field investigations show that it is quite common to get high quantities of mould in this wall system.

Figure 2: Predicted RH at the interior surface of the concrete foundation wall

Figure 3: Condensation potential for interior air on the surface of the concrete foundation wall

Constructability and Cost

This is the most inexpensive alternative in terms of initial capital cost, which is the reason it is chosen. Continuous roll batt makes finishing the basement with gypsum board difficult, unless the roll batt is removed.

Other Considerations

This wall is not recommended based on this analysis, other reports, and field investigations of moldy basements.

Reference

Mitalas, G.P., Calculation of Basement Heat Loss, National Research Council Canada.